When you need to know which rigging hardware is designed for vertical pulls, focus on equipment purpose-built for safe lifting. You should consider lifting clamps, swivel eyebolts, unshouldered eyebolts, vertical lifting slings, and shackles.

Synthetic slings carry up to 6,000 lbs, wire rope slings handle loads up to 36 tons, and chain slings support up to 100 tons. Selecting the right hardware prevents accidents and ensures reliability. Powerful Machinery provides certified solutions trusted worldwide for demanding vertical lifting tasks.

Key Takeaways

Select specialized rigging hardware for vertical pulls to ensure safety and effectiveness. Using the right equipment prevents accidents.

Always inspect rigging hardware before each use. Regular checks help identify worn or damaged equipment, reducing the risk of failure.

Understand the load ratings of your rigging devices. Ensure that the working load limit matches or exceeds the weight of the load you are lifting.

Use certified rigging hardware from reputable manufacturers. This guarantees compliance with safety standards and enhances reliability during lifts.

Maintain clear communication among your team during lifting operations. Effective communication helps prevent accidents and ensures safe handling.

Vertical Pulls in Rigging Hardware

What Are Vertical Pulls?

You encounter vertical pulls when you lift a load straight up using rigging hardware. This process requires you to move heavy objects vertically, often in construction, marine, or industrial settings. Vertical pulls demand precise control and reliable rigging to prevent accidents.

You rely on rigging hardware such as lifting clamps, slings, and shackles to secure the load and maintain stability. When you perform vertical pulls, you must ensure that the rigging hardware supports the weight and resists shifting.

You use vertical pulls to position beams, containers, or machinery safely. Rigging hardware designed for vertical pulls helps you achieve efficient lifting and protects both workers and equipment.

Why Specialized Rigging Hardware Matters?

You must select specialized rigging hardware for vertical pulls to guarantee safety and effectiveness. Using the wrong rigging hardware exposes you to serious risks. Consider the following hazards when you use non-specialized rigging hardware:

Overloading can cause equipment failure and dropped loads.

Improper sling angles reduce load capacity and increase the risk of failure.

Equipment failure may occur if you use defective rigging hardware.

Falling loads threaten injuries and property damage.

Swinging loads can strike workers or nearby objects.

Pinch points and crush hazards require you to stay alert and use proper PPE.

Environmental factors, such as weather, can impact rigging safety.

Electrical hazards arise when you work near energized lines or use defective tools.

You must follow industry regulations that specify the need for specialized rigging hardware in vertical lifting. The following table outlines key standards:

Standard | Description |

|---|---|

ASME B30.23 | Applies to hoisting equipment used to lift, lower, or transport personnel. |

ASME B30.24 | Covers container cranes for lifting purposes, including construction. |

ASME B30.25 | Pertains to scrap and material handlers, detailing their operation. |

ASME B30.26 | Focuses on detachable rigging hardware for load handling activities. |

You protect yourself and your team when you choose certified rigging hardware for vertical pulls. Specialized rigging hardware ensures that you meet safety standards and achieve reliable lifting results.

Which Rigging Hardware is Designed for Vertical Pulls?

When you need to know which rigging hardware is designed for vertical pulls, you must understand the strengths and limitations of each type. You rely on specialized rigging hardware to lift loads vertically with maximum safety and efficiency.

You use rigging equipment such as lifting clamps, swivel eyebolts, unshouldered eyebolts, vertical lifting slings, and shackles. Each rigging device serves a unique purpose in vertical lifting operations.

Lifting Clamps for Vertical Pulls

You use lifting clamps when you need to grip and lift steel plates or similar materials vertically. Vertical lifting clamps keep your load steady and secure during the lift. You benefit from their locking systems, which hold onto the material tightly and distribute force evenly.

The hinge design enhances stability and safety. You must always select a lifting clamp with a working load limit close to your cargo’s weight. Vertical lifting clamps handle weights from 500kg to 5000kg, depending on the model. Proper usage is essential to avoid accidents or damage.

Vertical clamps keep the load steady and secure during lifting.

They significantly enhance safety levels when handling materials.

Vertical plate clamps provide a secure grip on materials lifted.

Improper usage can lead to damage or accidents.

They may leave marks on the materials’ surface.

Vertical lifting clamps use a locking system to hold onto the material securely.

They are designed to handle various shapes and sizes of loads, distributing force evenly.

The hinge design enhances stability and safety when lifting.

Tip: Always inspect your lifting clamps before use. You prevent accidents by following manufacturer guidelines and using clamps within their rated capacity.

Swivel Eyebolts and Unshouldered Eyebolts

You use eyebolts to attach rigging hardware to loads for vertical pulls. Swivel eyebolts and unshouldered eyebolts are common choices. Swivel eyebolts pivot and swivel, making them versatile for both vertical and angled pulls.

Unshouldered eyebolts are only safe for true vertical lifts. If you use unshouldered eyebolts for angled pulls, they may bend or fail.

Eyebolt Type | Suitability for Vertical Pulls | Suitability for Angled Pulls |

|---|---|---|

Swivel Eyebolts | Yes | Yes |

Unshouldered Eyebolts | Yes | No |

You should use swivel eyebolts for both vertical and angled lifts to ensure safety. You must avoid using unshouldered eyebolts for anything other than vertical lifts.

Vertical Lifting Slings and Shackles

You rely on vertical lifting slings and shackles to connect loads to lifting hardware. Slings come in several types, including wire rope, chain, synthetic web, and round slings. Shackles act as U-shaped connectors, linking slings, hooks, and loads in rigging assemblies.

You select the right sling width and type based on your load requirements.

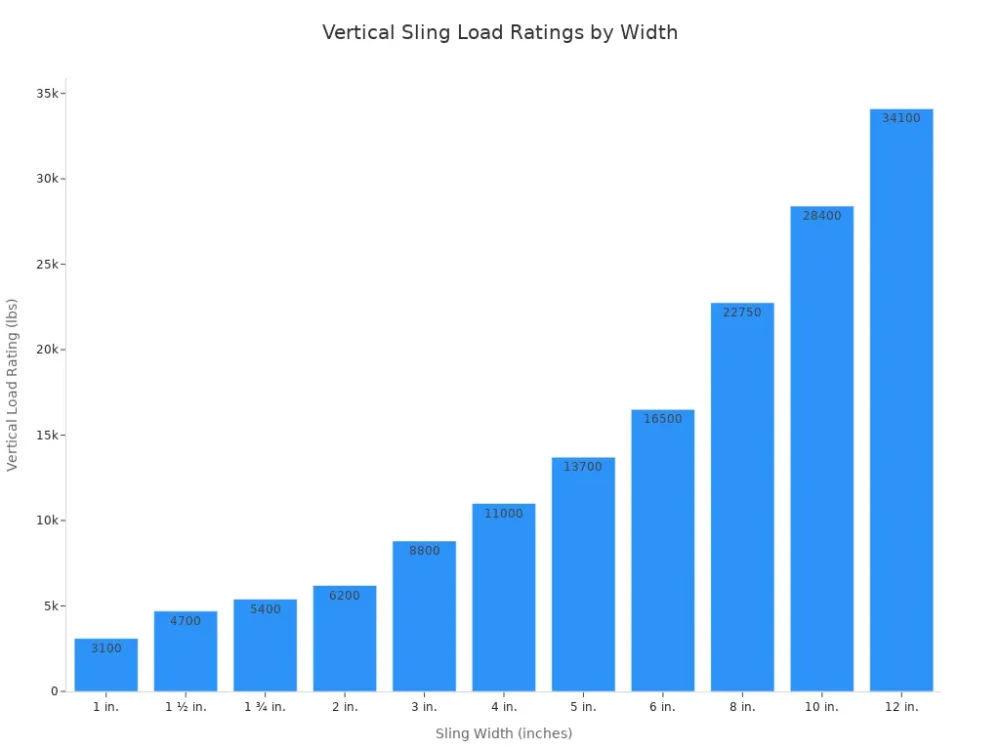

Sling Width (in.) | Vertical Load Rating (lbs) |

|---|---|

1 | 3,100 |

1 ½ | 4,700 |

1 ¾ | 5,400 |

2 | 6,200 |

3 | 8,800 |

4 | 11,000 |

5 | 13,700 |

6 | 16,500 |

8 | 22,750 |

10 | 28,400 |

12 | 34,100 |

You use synthetic slings for lighter loads up to 6,000 lbs. Wire rope slings handle loads up to 36 tons. Chain slings support up to 100 tons. Shackles provide secure connections in crane rigging, heavy equipment lifting, and towing.

You choose slings for flexibility and load handling. You select shackles for secure connections in rigging assemblies.

Feature | Slings | Shackles |

|---|---|---|

Shape | Flexible lifting devices | U-shaped connectors |

Function | Connect loads to lifting equipment | Link slings, hooks, and loads |

Types | Wire Rope, Chain, Synthetic Web, Round Slings | Anchor Shackles, Chain Shackles |

Load Capacity | Varies by type; e.g., synthetic slings up to 6,000 lbs, wire rope up to 36 tons | Varies; chain shackles can carry up to 100 tons |

Applications | Used in shipping, construction, and marine operations | Used in crane rigging, heavy equipment lifting, and towing |

Design Purpose | Designed for flexibility and load handling | Designed for secure connections in rigging assemblies |

Note: You must match the sling or shackle type to your specific rigging application. You ensure safety by checking load ratings and inspecting your rigging devices before each lift.

Powerful Machinery Certified Hardware

You need certified rigging hardware for vertical pulls to meet international safety standards. Powerful Machinery provides a full range of lifting hardware, including lifting clamps, eyebolts, slings, and shackles. You benefit from products that meet or exceed standards such as OSHA, ASME B30.9, NACM, and ASTM.

Standard | Description |

|---|---|

OSHA | Ensures compliance with safety regulations for lifting equipment. |

ASME B30.9 | Requires proofloading of alloy lifting chain assemblies before use. |

NACM | Specifies chain specifications and requirements for safe use. |

ASTM | Sets standards for materials and performance of chains used in lifting. |

You receive documentation for compliance, including proof of OSHA training, written safety programs, and inspection records. Powerful Machinery’s rigging hardware undergoes rigorous testing to guarantee reliability in demanding environments.

You trust Powerful Machinery for certified rigging equipment that supports safe and effective vertical pulls.

Alert: You should always choose certified rigging hardware from reputable manufacturers. You protect your team and your equipment by prioritizing safety and compliance.

You now know which rigging hardware is designed for vertical pulls. You can select the right rigging equipment for your lifting needs and ensure every lift meets the highest safety standards.

Selecting Rigging Hardware for Vertical Lifts

Load Ratings and Material

You must evaluate load ratings before you select rigging hardware for vertical lifts. Working load limits help you determine if the rigging can safely support your intended load. Rated capacity should match or exceed the working load limit of the wire rope or chain you use.

Minimum breaking load shows the point at which rigging hardware may fail, so you need to calculate the working load limit based on this value. Safety factors give you a margin of error for unexpected conditions.

Working load limits ensure safe lifting operations.

Rated capacity must align with your rigging system.

Minimum breaking load helps you avoid hardware failure.

Safety factors protect you from unforeseen risks.

Material selection also impacts performance. Wire ropes consist of twisted steel strands, offering strength and flexibility for hoists and cranes. Chains work well for securing and lifting heavy loads, especially in rugged or high-temperature environments.

You should always choose rigging hardware made from high-quality materials to maximize durability and safety.

Compatibility and Certification

You need to confirm compatibility between all rigging devices in your system. Matching the grade of the hook with the grade of the chain or rigging hardware prevents compromised safety and performance. Incompatible rigging equipment can lead to dangerous situations.

Certification is essential for compliance and reliability. International certifications validate the quality and safety of your rigging hardware. The following table highlights recognized certifications for lifting hardware:

Certification Name | Description |

|---|---|

Lifting Accessories Inspector | Examines and evaluates lifting accessories per regulations. |

Lifting and Rigging Inspector | Identifies hazards and verifies compliance for lifting equipment inspections. |

Lifting and Rigging Safety Specialist | Provides advanced training for supervisors on lift planning and risk assessments. |

Lifting Equipment Safety | Covers safe use of lifting equipment and handling protocols. |

You should also look for NCCCO and NCCER rigging certifications, which are widely recognized in the United States for rigging and signal operations.

Tip: Always verify that your rigging hardware meets international standards before use.

Powerful Machinery Solutions

Powerful Machinery offers custom solutions for unique vertical lifting requirements. You can request custom-fabricated beams for non-standard load shapes or limited clearance. Multi-leg chain sling assemblies enhance stability and capacity beyond standard rigging devices.

Specialized lifting hooks address lifting needs that standard hooks cannot fulfill.

Custom Rigging Solutions | Applications |

|---|---|

Custom-fabricated beams | Non-standard load geometries and limited clearance situations |

Multi-leg chain sling assemblies | Enhanced stability and capacity |

Specialized lifting hooks | Unique lifting requirements |

You benefit from a comprehensive product range, including JIS stainless steel lifting eye nuts, high-tensile lifting chains, hooks, shackles, wire rope fittings, and custom-engineered rigging hardware.

Powerful Machinery ensures every piece of rigging equipment meets or exceeds industry benchmarks for vertical lifting. You receive certified products that guarantee safety and reliability for every lift.

🛠️ Choose Powerful Machinery for certified rigging hardware and custom solutions that meet the toughest demands in vertical lifting.

Safety in Vertical Rigging

Inspection and Installation

You must inspect rigging hardware before every vertical lift. Regular inspection helps you identify worn or damaged rigging equipment, preventing failures during operation.

The inspection interval depends on your service conditions. For normal service, inspect your rigging hardware yearly. If you operate in severe conditions, inspect monthly or quarterly. Special service requires inspection as recommended by a qualified person.

Service Type | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified person |

When installing rigging devices, you need to avoid common errors that can lead to accidents. Overloading the crane, choosing the wrong sling, or attaching lifting devices incorrectly can cause instability. You must check the angle of lift and use only undamaged rigging hardware.

Always perform a test lift and use slings of the same length and type. Proper communication and ground support are essential for safe lifting.

Overloading the crane

Incorrect sling selection

Improper load attachment

Incorrect angle of lift

Using damaged or worn rigging equipment

Failure to perform a test lift

Using slings of different lengths or types

Improper use of hooks and shackles

Failure to ensure proper communication

Lifting loads for extended periods

Lifting loads from the wrong position

Ignoring environmental factors

Inadequate ground support

Lack of a spotter

Powerful Machinery supports your safety with regular inspections, proof testing, and safety seminars. Their team repairs self-retracting lifelines and checks lifting hardware to ensure reliability.

Usage Tips for Vertical Pulls

You improve safe lifting by following essential safety tips for rigging operations. Always inspect rigging equipment before each shift and during use. Never exceed the rated capacity of your rigging hardware. Only qualified riggers should operate lifting devices.

Maintain clear communication between the crane operator and the rigging crew.

Safety Tip | Description |

|---|---|

Inspection | Rigging equipment must be inspected before use on each shift and as necessary during its use. |

Safe Working Load | Rigging equipment must not be loaded beyond its rated capacity, with limits clearly marked. |

Qualified Riggers | Only qualified riggers should perform rigging work, ensuring safety through proper training. |

Communication | Effective communication must be maintained between the crane operator and the rigging crew. |

You must stay alert to the most common causes of accidents in vertical rigging. Falls account for nearly 40% of fatalities, often due to miscommunication or improper use of rigging hardware.

Transportation accidents, contact with objects, and exposure to harmful environments also pose risks. You protect yourself and your team by following safety protocols and using certified lifting hardware.

🛡️ Powerful Machinery’s commitment to safety means you receive reliable rigging hardware, thorough inspections, and expert guidance for every vertical lift.

Conclusion

You rely on lifting clamps, swivel eyebolts, unshouldered eyebolts, vertical lifting slings, and shackles for safe vertical pulls. Always select hardware rated for overhead lifting and inspect it before each use.

Choose equipment in good condition

Calculate load weight and center of gravity

Train regularly and maintain certification

Communicate clearly with your team

Avoid overloading and improper sling usage

Choosing certified rigging hardware ensures safety and compliance. Powerful Machinery provides tested solutions you can trust. Make safety your priority and inspect your equipment regularly.

FAQ

What is the safest rigging hardware for vertical pulls?

You should use certified lifting clamps, swivel eyebolts, unshouldered eyebolts, vertical lifting slings, and shackles. These devices support vertical loads and meet international safety standards. Always check the load rating before use.

How often should you inspect rigging hardware?

You must inspect rigging hardware before every use. For normal service, inspect yearly. For severe conditions, inspect monthly or quarterly. Replace any damaged or worn components immediately.

Can you use horizontal lifting clamps for vertical pulls?

No. You must use vertical lifting clamps for vertical pulls. Horizontal clamps do not provide the necessary grip or safety for vertical lifting. Always match the clamp type to your lifting direction.

Why do certifications matter for rigging hardware?

Certifications prove that your rigging hardware meets strict safety and quality standards. You reduce accident risks and ensure compliance with industry regulations by choosing certified products from trusted brands like Powerful Machinery.

Where can you buy certified rigging hardware for vertical pulls?

You can purchase certified rigging hardware directly from Powerful Machinery. Visit Powerful Machinery’s official website to explore their full range of lifting solutions and request custom products.