You want to know which type of rigging equipment is used to balance loads. The main types include slings, spreader beams, lifting beams, shackles, hooks, wire ropes, pulleys, and turnbuckles. You must select the right rigging equipment to balance loads safely and efficiently.

Powerful Machinery offers certified rigging equipment that meets OSHA and ASME standards. You can trust Powerful Machinery for rigging equipment that handles loads and follows OSHA and ASME requirements. Always choose certified rigging equipment for balancing loads in compliance with OSHA and ASME.

Which type of rigging equipment is used to balance loads?

Which type of rigging equipment is used to balance loads in your project?

Which type of rigging equipment is used to balance loads according to OSHA?

Which type of rigging equipment is used to balance loads that meet ASME?

Which type of rigging equipment is used to balance loads with certified rigging equipment?

Key Takeaways

Choose the right rigging equipment, like slings, shackles, and beams, to balance loads safely.

Always use certified rigging equipment that meets OSHA and ASME standards for safety and reliability.

Inspect your rigging gear before each use to ensure it is in good condition and safe for lifting.

Understand the load type and weight to select the appropriate rigging setup for your project.

Consult with experts at Powerful Machinery for tailored rigging solutions that fit your specific needs.

Types of Rigging Equipment for Load Balancing

When you need to balance loads safely, you must choose the right rigging equipment. Powerful Machinery offers a complete range of rigging devices designed for industrial, construction, and marine applications.

Each product meets strict international standards, ensuring you get certified strength, traceability, and compliance for every lift.

Slings and Wire Ropes

Slings and wire ropes form the backbone of most rigging systems. You use slings to connect loads to hoists, cranes, or other lifting devices. Powerful Machinery manufactures slings from high-tensile steel, synthetic fibers, and chains. Each type of sling serves a unique purpose in rigging operations.

Wire rope slings offer flexibility and strength. You can use them for heavy-duty lifting in construction, marine, and oil and gas industries.

Chain slings provide durability and resist abrasion. You often use them for rugged environments and repetitive lifting.

Synthetic slings are lightweight and gentle on delicate loads. They work well for handling finished products or sensitive equipment.

Wire ropes from Powerful Machinery come in galvanized and stainless steel options. In marine environments, stainless steel wire ropes resist saltwater corrosion, making them ideal for securing and lifting. In food processing, stainless steel wire ropes maintain hygiene and durability.

The oil and gas sector relies on high-strength wire ropes to withstand harsh conditions and ensure safety.

Tip: Always check the load rating and certification of your slings and wire ropes before use. Certified rigging equipment from Powerful Machinery meets Grade 80 and Grade 100 standards, supporting safe and reliable lifting.

Shackles and Hooks

Shackles and hooks are essential rigging devices that connect slings, chains, and other rigging equipment to loads and lifting points. You rely on shackles for secure connections and hooks for attaching to lifting devices or anchor points.

Functionality | Description |

|---|---|

Smart Shackles | Monitor load weight in real-time, preventing overload accidents. |

Integrated Lifting Hooks | Connect securely with loads, reducing slippage risk. |

Importance of Design | Features for smooth load control, maintaining stability and preventing accidents. |

Safety Features | Rated for loads; hooks with safety latches prevent accidental disengagement. |

Powerful Machinery manufactures shackles and hooks from high-tensile steel and stainless steel. Each component meets ISO and ASTM standards, ensuring strength and durability. Certification processes guarantee compliance with international regulations, reducing the risk of accidents and increasing reliability.

Always use shackles and hooks rated for the loads you plan to lift.

Safety latches on hooks prevent accidental disengagement.

Design features allow gradual lifting and lowering, reducing sudden movements.

You can trust Powerful Machinery’s shackles and hooks for critical rigging operations. Each product is fully traceable, supporting compliance and simplifying inspections.

Spreader Beams and Lifting Beams

Spreader beams and lifting beams help you balance loads by distributing weight across multiple lifting points. These rigging devices play a vital role in handling wide, long, or uneven loads.

Spreader beams convert lifting loads into compressive forces. You use them to distribute weight evenly across two or more lifting points. This makes them ideal for wide or heavy-duty loads.

Lifting beams convert lifting loads into bending forces. You attach them at a single point, which can sometimes lead to tipping or spinning. Lifting beams work best for shorter spans or when you have limited overhead space.

You can find spreader beams that are adjustable in length, making them versatile for different rigging jobs. Lifting beams have a simple design and support loads that are too weak or flexible to lift without extra support.

Spreader beams from major manufacturers handle up to 40 tons with spreads up to 42 feet.

Heavy-duty models can handle loads up to 375 tons.

Spreader bars have a working load limit ranging from 2,000 lbs to over 100,000 lbs.

Powerful Machinery offers both spreader beams and lifting beams, each certified for strength and traceability. You can select the right beam for your rigging systems, ensuring safe and balanced lifting every time.

Pulleys, Blocks, and Turnbuckles

Pulleys, blocks, and turnbuckles are key rigging devices for complex lifting and load balancing. You use pulleys and blocks to change the direction of force and gain mechanical advantage. This allows you to lift heavy loads with less effort.

Blocks and pulleys are wheel-based systems that optimize lifting operations. You can use them to increase lifting capacity and change the direction of force.

Block and tackle systems combine pulleys (blocks) and ropes or chains (tackle). These systems multiply the applied force, making it easier to lift heavy loads.

Turnbuckles adjust the tension or length of ropes, cables, and other tensioning systems. You use them to fine-tune rigging setups for precise alignment and load distribution.

Axle Type | Efficiency Rating |

|---|---|

Ball Bearing Axles | ~90% |

Bushing Axles | 65% – 80% |

Larger Sheaves (50mm) | 85% – 90% |

Smaller Sheaves | 80% – 85% |

You can achieve high efficiency in your rigging systems by choosing the right pulleys and blocks. Powerful Machinery provides certified pulleys, blocks, and turnbuckles, each designed for maximum performance and safety.

Note: Always inspect your rigging equipment before use. Certified rigging devices from Powerful Machinery support compliance with OSHA, ISO 45001, and other major standards.

Certifications and Compliance

When you select rigging equipment, you must ensure it meets industry standards and certifications. Powerful Machinery’s products comply with the following:

Certification | Description |

|---|---|

ISO 45001 | Focuses on occupational health and safety, ensuring a safe workplace and minimizing risks during operations. |

ISO 14001 | Addresses environmental management, promoting responsible practices in rigging operations to reduce environmental impact. |

OSHA Compliance | Ensures adherence to safety regulations in the workplace, crucial for rigging operations. |

NCCCO Certification | Validates the skills and knowledge of riggers, ensuring they meet industry standards for safety and competence. |

Qualified riggers must have recognized certifications or extensive training.

Rigger certification demonstrates competence and adherence to industry standards.

Candidates must pass written and practical evaluations to prove their skills.

Powerful Machinery’s rigging equipment is fully traceable, supporting compliance and reducing risk during inspections. You can rely on these products for safe, efficient, and certified lifting operations in any environment.

How Rigging Equipment Balances Loads?

Load Distribution Methods

You need to understand how rigging equipment helps you balance loads during lifting. Rigging works by spreading the weight across several points. This prevents any single part from carrying too much weight. You must always check the center of gravity before you move loads.

If you use slings, chains, or cables, you can share the weight among different rigging components. The angle of your slings changes how the rigging distributes the weight. When you use spreader bars, you keep tension even across all rigging points. This method keeps loads stable and safe as you move loads.

You should also consider dynamic loading, which happens when forces change quickly. Different rigging setups, like bridles or basket hitches, give you options for balancing loads in many situations.

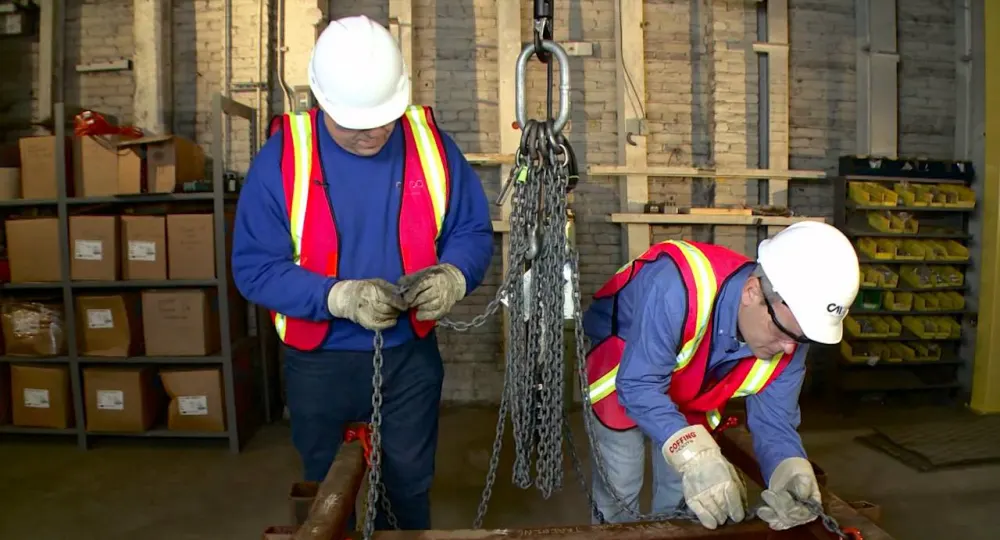

Typical Applications in Rigging

You use rigging every day to move loads in construction, marine, and industrial settings. In construction, you rely on wire ropes and chains to connect heavy materials to cranes. You use hooks to attach loads to your rigging system. In marine work, you choose galvanized or stainless steel wire ropes to resist corrosion.

Marine cranes often move loads that are heavy and uneven, so you need proper rigging to keep everything stable. You must inspect your rigging often, especially in salty environments, to avoid corrosion and broken wires. In factories, you use rigging to move loads like machinery and steel beams.

Each rigging component plays a role in keeping your lifting safe and balanced.

Construction: Move loads like steel beams and concrete panels.

Marine: Use rigging to lift and move loads on ships and docks.

Industry: Rigging helps you move loads in manufacturing plants.

Advantages of Powerful Machinery Rigging Equipment

You gain many benefits when you choose Powerful Machinery for your rigging needs. Their rigging products meet strict international standards, such as ISO, OSHA, and ASME. Every chain and wire rope goes through tough testing for safety and reliability.

Powerful Machinery uses advanced technology, like automated welding and precision forging, to make rigging with a strong structure and consistent quality. You can order custom rigging solutions for your project. Their global export network ensures you get your rigging on time, wherever you work.

You can trust Powerful Machinery to help you move loads safely and efficiently.

Feature | Benefit |

|---|---|

Direct Manufacturer | Lower costs, fast delivery |

Custom Solutions | Fit your project needs |

Advanced Technology | Reliable, high-quality rigging |

Global Export Network | On-time delivery worldwide |

Tip: Always use certified rigging from Powerful Machinery to move loads with confidence and meet safety standards.

Which Type of Rigging Equipment Is Used to Balance Loads: Selection Guide

Assessing Load Type and Weight

You must start every rigging operation by assessing the type and weight of the loads you plan to move. Accurate assessment helps you select the right lifting devices and rigging equipment for safe and efficient lifting. You need to consider several factors before you choose your rigging setup:

You must know the total load weight, which includes the mass of the load, rigging gear, and any attachments.

You should check the working load limit for every rigging component. Each piece of rigging has a maximum safe load capacity.

You need to understand the shape, balance, and fragility of the loads. Some loads require special rigging techniques or materials.

You must ensure that your lifting devices are rated for the maximum load capacity. Never exceed the working load limit to maintain safety.

You should balance the load to avoid equipment failure or unnecessary expenses.

Tip: Always calculate the total weight before you select your rigging equipment. This step helps you avoid overloads and keeps your lifting rigging safe.

Environmental and Safety Considerations

You must consider the environment and safety requirements when you choose rigging equipment for balancing loads. Different environments affect the performance and durability of your rigging gear. The table below shows how sling types respond to environmental and safety factors:

Sling Type | Environmental Considerations | Safety Considerations |

|---|---|---|

Synthetic Web Slings | Vulnerable to cutting, heat, and chemical damage | Lightweight and flexible; excellent for fragile surfaces |

Synthetic Round Slings | Internal damage may go undetected | Similar surface protection and flexibility |

Wire Rope Slings | Prone to wear at contact points | Provides rigidity and temperature resistance |

Alloy Steel Chain Slings | Suitable for harsh environments | Exceptionally durable but can damage sensitive surfaces |

Temperature, humidity, and corrosive conditions play a major role in your rigging choices. Steel chain slings can handle high temperatures, while synthetic slings work best in moderate climates. In marine or saltwater environments, you should use stainless steel rigging to resist corrosion.

You must inspect your rigging regularly to maintain safety and prevent failures.

Note: Always match your rigging equipment to the environment and safety needs of your project. This practice helps you protect your loads and your team.

Matching Powerful Machinery Products to Your Needs

You can match Powerful Machinery’s certified rigging equipment to your specific load balancing requirements. Powerful Machinery offers a wide range of lifting devices, including slings, hooks, shackles, wire ropes, pulleys, blocks, spreader beams, and lifting beams.

Each product meets strict international standards and comes with a clear working load limit.

In construction, you can use wire rope slings and alloy steel chain slings for heavy loads and structural materials.

In marine operations, you should select stainless steel wire ropes and corrosion-resistant shackles for lifting and securing loads in harsh environments.

In manufacturing, you can use synthetic slings for delicate machinery and finished products.

You can request custom-engineered rigging solutions from Powerful Machinery to fit unique project needs. Every product is traceable and certified for safety.

Powerful Machinery helps you optimize your rigging setup for every industry. You can rely on their lifting rigging products to balance loads, maintain safety, and meet operational demands.

You get support from initial consultation to final production, ensuring your rigging equipment matches your lifting devices and working load limit requirements.

🛠️ Tip: Consult Powerful Machinery for certified rigging equipment that fits your load, environment, and safety needs. Their experts help you select the right rigging for every application.

Rigging Safety and Inspection Tips

Rigging safety should always be your top priority. You protect yourself and your team by following strict safety protocols and inspecting your rigging equipment before every lift. Powerful Machinery designs all rigging products to meet international safety standards, so you can trust their equipment for every job.

Pre-Use Inspection Guidelines

You must inspect all rigging gear before each use. Look for these issues:

Cuts, burns, broken wires, or kinks in slings.

Missing identification tags on slings.

Bent shackles, damaged threads, or mismatched pins.

Hooks that show deformation or have latches that do not close.

Signs of wear, corrosion, or fraying on any rigging hardware.

Check that your rigging matches the lift requirements, including capacity and sling angle. Protect sharp edges with padding or corner protectors. Always balance the load and confirm clear communication with your team. Never allow anyone under a suspended load.

Tip: Keep a record of all inspections and replace damaged equipment immediately.

Safe Handling and Operation

You extend the life of your rigging equipment and improve safety by following best practices:

Store rigging gear in a dry, clean, and organized area.

Lubricate moving parts and clean equipment after use.

Rotate loads when possible to prevent uneven wear.

Train all personnel in proper rigging techniques and load balancing.

Conduct comprehensive inspections before each lift.

Regular maintenance and proper storage prevent hazards and keep your rigging ready for safe operation. Safety training ensures everyone understands how to use rigging equipment correctly.

Training Component | Description |

|---|---|

Roles & Responsibilities | Duties for all team members in rigging operations |

Regulations and Standards | Covers OSHA and industry safety standards |

Inspections | How to check rigging and understand load limits |

Certification | Wallet certificates after passing the training |

Common Mistakes to Avoid

You can avoid many rigging accidents by steering clear of these common mistakes:

Skipping equipment inspections.

Ignoring load limits and overloading rigging gear.

Using the wrong hitch type for the load.

Forgetting to protect slings from sharp edges.

Pro Tip: Even a small change in sling angle can increase tension and risk equipment failure. Always check your setup before lifting.

By following these guidelines and using Powerful Machinery’s certified rigging, you help ensure every lift is safe and successful.

Conclusion

You have many options for balancing loads, such as slings, spreader beams, lifting beams, shackles, hooks, and wire ropes. Choosing the right equipment keeps your lifts safe and efficient. Always use certified products like those from Powerful Machinery.

Regular inspections and safe handling protect your team and your investment. For expert advice and certified rigging solutions, contact Powerful Machinery today.

FAQ

What is the most important factor when choosing rigging equipment?

You must check the working load limit. This ensures your rigging equipment can handle the weight safely. Always verify certifications and match the equipment to your specific lifting needs.

How often should you inspect rigging equipment?

You should inspect rigging equipment before every use. Schedule regular inspections based on how often you use the gear and the environment. Replace damaged items immediately.

Which rigging equipment helps balance uneven loads?

You use spreader beams and lifting beams to balance uneven loads. These devices distribute weight across multiple points, keeping the load stable during lifting.

What certifications do Powerful Machinery products meet?

Certification | Description |

|---|---|

ISO9001 | Quality management |

OSHA | Safety standards |

ASTM | Material specifications |

You get certified products that meet international standards for safety and reliability.

Can you customize rigging equipment for special projects?

Yes, you can request custom-engineered rigging solutions from Powerful Machinery. Their team helps you design equipment that fits your project requirements.

Tip: Always consult with experts before starting a new rigging project.