Rigging Equipment

Rigging equipment makes every lift safer and more controlled when loads get heavy. We manufacture rigging equipment ourselves, manage quality from start to finish, and help you match the right gear to the job. Quote rigging equipment from Powerful Machinery today.

Built with defined load ratings and safety factors to support lifts with confidence and control.

Produced to meet Grade 80, Grade 100, and industry standards for consistent jobsite acceptance.

Each product supports traceability and compliance to reduce risk and simplify inspections.

Factory-controlled output supports bulk orders, stable lead times, and predictable pricing.

Featured Partners for Lifting and Rigging Equipment

We work with industry leaders to provide dependable lifting and rigging equipment supply.

RIGGING EQUIPMENT COLLECTIONS

Our rigging equipment collection helps you lift, pull, and secure loads with confidence. We organize each product clearly so you choose the right rigging equipment faster and keep operations safe and efficient across daily lifting tasks.

SLINGS

A flexible, lightweight tool used with wire ropes to lift heavy loads

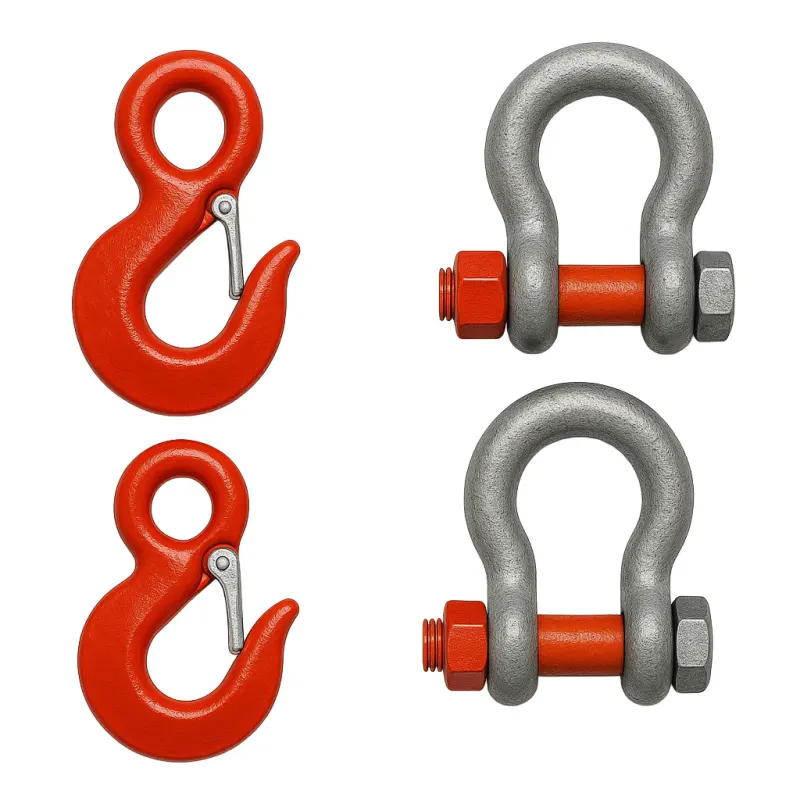

RIGGING HOOK & SHACKLE

Connects chains, ropes, slings, and other riggingequipment to prevent them from slipping

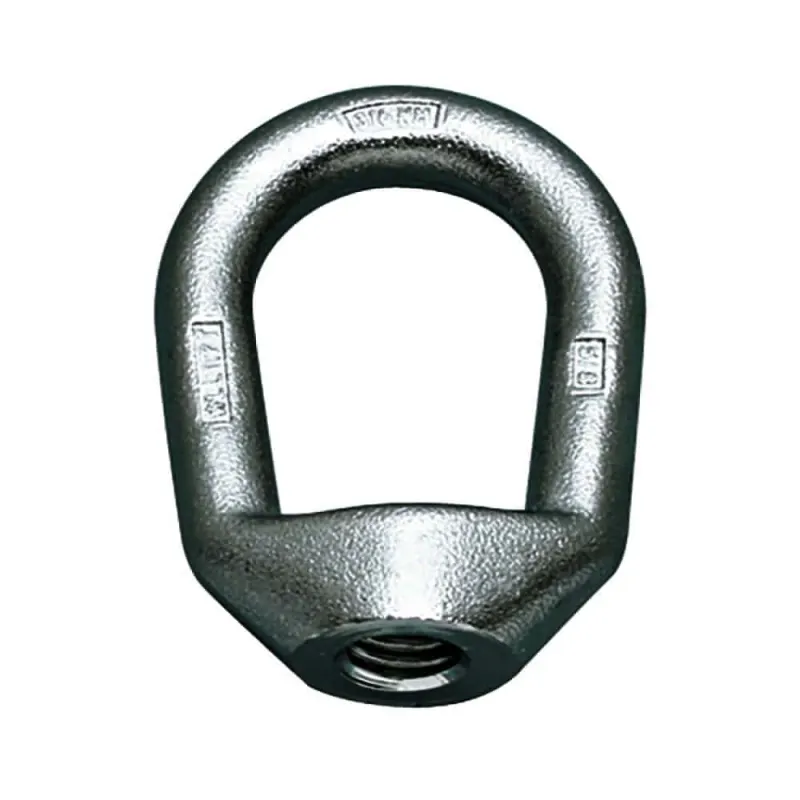

EYE NUT

Works with the eye bolts in anchoring a riggingsystem

TURNBUCKLES

Adjusts the length or tension on a cable, chain,rope, and other tensioned rigging equipment

SPREADER BARS & LIFTING BEAMS

Stabilize the weight of the load for a moremanageable lift

ANY SHAPE. ANY SIZE. NOT A PROBLEM

Rigging equipment includes many components that work together to build custom lifting assemblies for industrial and construction jobs. Each part plays a role in handling heavy loads safely and accurately.

Our rigging range covers turnbuckles, rigging screws, lifting and spreader beams, load arrestors, chains and components, wire rope, snatch blocks, wire rope fittings, and swivels. You can combine these items to match different lifting requirements.

LET THE PROFESSIONALS MANAGE THE DETAILS

GLOBAL SHIPPING SERVICES

No Shipment is Too Large or Too Small. We Deliver Worldwide by Sea, Road, or Air Freight.

CHOOSE THE PAYMENT METHOD THAT SUITS YOU

FLEXIBLE PAYMENT OPTIONS

We Support Multiple Payment Methods, From Debit Cards to Opening a Credit Account With Us.

NEED HELP WITH YOUR ORDER?

Let us help! Reach out today and get recommendations on materials and sizing from our experts.

RIGGING EQUIPMENT GUIDE

Rigging Equipment selection impacts safety and efficiency. Explore our guide to understand where each hardware type works best.

What is Rigging Equipment?

Rigging equipment includes tools and hardware that control, lift, position, secure, or stabilize heavy loads during handling or installation. We design rigging equipment to connect loads to cranes, hoists, winches, or anchor points with predictable behavior under stress.

Rigging equipment covers chains, wire rope, slings, shackles, hooks, turnbuckles, swivels, beams, blocks, and connectors. Each component serves a defined role inside a lifting system.

Types of Rigging Equipment

Rigging equipment types group by function rather than shape. We manufacture load connection hardware, load control devices, and load distribution tools.

• Connection hardware: shackles, hooks, master links, rings

• Flexible elements: chain slings, wire rope slings, synthetic slings

• Load control: turnbuckles, load arrestors, swivels

• Distribution tools: lifting beams, spreader beams

• Motion tools: snatch blocks, rigging blocks

Each type works together inside a lifting plan. Correct selection reduces shock load, side load, and wear during daily operations.

How Often Must Rigging Equipment Be Inspected?

Rigging equipment needs inspection before every use and at defined intervals based on duty cycle, environment, and risk level.

Operators should check hardware daily for cracks, deformation, corrosion, wear, tag loss, and improper fit. Qualified inspectors should perform scheduled inspections monthly, quarterly, or annually depending on usage severity. High-cycle lifting, outdoor exposure, marine use, or heat exposure require shorter inspection intervals. Inspection frequency protects load integrity and keeps lifting plans compliant with site safety rules.

Rigging Equipment Inspection Checklist

A rigging equipment inspection checklist guides consistent decisions across teams and sites. We build inspection points into our designs to simplify checks.

• Verify identification tags and working load limits

• Check for cracks, bends, elongation, gouges, corrosion

• Measure chain and wire rope wear against limits

• Inspect hooks for throat opening and latch function

• Confirm shackle pin fit and thread condition

• Check sling stitching, fibers, or broken wires

• Review storage damage and heat exposure signs

Rigging Equipment Repair

Rigging equipment repair requires strict control and clear rules. Proper repair protects load integrity, maintains safety, and prevents unexpected failure during lifting operations.

Key rules for rigging equipment repair:

Repair only approved components under manufacturer guidance

Replace chain links using certified parts with controlled heat treatment

Re-terminate wire rope slings through qualified professional processes

Repair hooks only within defined reshaping limits and after crack testing

Never weld, drill, or modify shackles

Reject equipment when repairs alter load paths or material structure

Use documented repair programs with traceable replacement parts and clear rejection criteria

Rigging Equipment Certification

Rigging equipment certification confirms strength, material traceability, and compliance. We certify products through controlled manufacturing, heat treatment records, and proof testing. Buyers search for certification clarity more than logos. Certification includes material grade, working load limit, safety factor, test load, and serial identification. Documents support audits, government projects, and rental operations. Certified rigging equipment reduces liability and simplifies site approval. Manufacturer-issued certificates provide consistency across global supply chains.

Which Type of Rigging Equipment is Used to Balance Loads?

Load balancing relies on equipment that controls force distribution. Lifting beams and spreader beams handle uneven loads and long structures. Swivels reduce torsion during rotation. Adjustable slings and turnbuckles fine-tune load position. Search data shows frequent interest in balance control for machinery moves.

Balanced lifts reduce side loading, sling damage, and crane instability. We design balancing tools with clear pick points and rated configurations to support predictable behavior during complex lifts.

Proof Testing of Rigging Equipment

Proof testing verifies strength under controlled overload. We proof test rigging equipment to confirm material integrity and manufacturing consistency. Test loads exceed working load limits without causing damage. Proof testing identifies defects before site use.

Rigging Equipment Safety

Rigging equipment safety depends on correct selection, inspection, training, and use. We design products with clear markings and predictable behavior. Safety questions focus on misuse rather than defects. Crews must respect working load limits, avoid shock loading, prevent side loading, and protect equipment from heat and chemicals.

Rigging Equipment Storage

Correct storage prevents damage, simplifies inspections, and lowers long-term replacement costs.

Best practices for rigging equipment storage:

Store rigging equipment in dry, clean, and well-organized areas

Separate equipment by type, size, and rated capacity

Hang chains and slings to prevent twisting and deformation

Protect wire rope from moisture, dirt, and surface abrasion

Keep identification tags visible and readable at all times

Avoid stacking heavy items in ways that cause bending or stress

What is the Most Common Misuse of Rigging Equipment?

The most common misuse involves exceeding working load limits or applying side loads. Crews often mismatch hardware sizes or ignore angle factors. Shackle side loading and sling angle errors. Misuse shortens equipment life and raises failure risk.

What Links Pieces of Rigging Equipment?

Connectors link rigging equipment into a system. Shackles, master links, hooks, and rings transfer load between components. Each link must match capacity and geometry. Weak links control system strength. Mmatched components maintain load continuity and reduce unexpected stress points during lifts.

When Must Rigging Equipment Be Inspected?

Rigging equipment requires inspection before use, after impact, after overload, after environmental exposure, and at scheduled intervals. Any drop, shock, or heat exposure triggers inspection. Clear inspection timing prevents hidden damage from entering service and protects lifting operations across all industries.

Have More Questions?

By understanding the specific uses of different types of rigging equipment and their compatibility with various rigging equipment, you can make informed decisions and choose the right components for your lifting needs. For more information or help selecting euipment, please contact us today.