You depend on rigging equipment for material handling to move heavy loads safely and efficiently. This equipment forms the backbone of many operations in construction, manufacturing, and cargo handling. Certified rigging equipment for material handling reduces risk and protects workers.

Studies show that 60% of crane-related fatalities result from rigging failure, making proper selection and inspection vital. You must inspect rigging equipment for material handling before each shift and ensure all load markings remain clear and permanent.

By choosing certified rigging equipment for material handling, you help prevent accidents and keep your site compliant. Rigging equipment for lifting must never exceed its rated capacity, and unused gear should be removed from the work area.

Rigging equipment for material handling keeps your team safe.

Pre-planned suspended load routes protect everyone on site.

Key Takeaways

Always inspect rigging equipment before each use to ensure safety and compliance.

Select the right type of rigging equipment based on load weight, environment, and specific lifting tasks.

Use certified rigging products to reduce risks and enhance operational efficiency.

Implement a formal safety program to train your team on best practices and maintain high safety standards.

Maintain traceability of rigging equipment to support compliance and quickly address any issues.

Types of Rigging Equipment for Material Handling

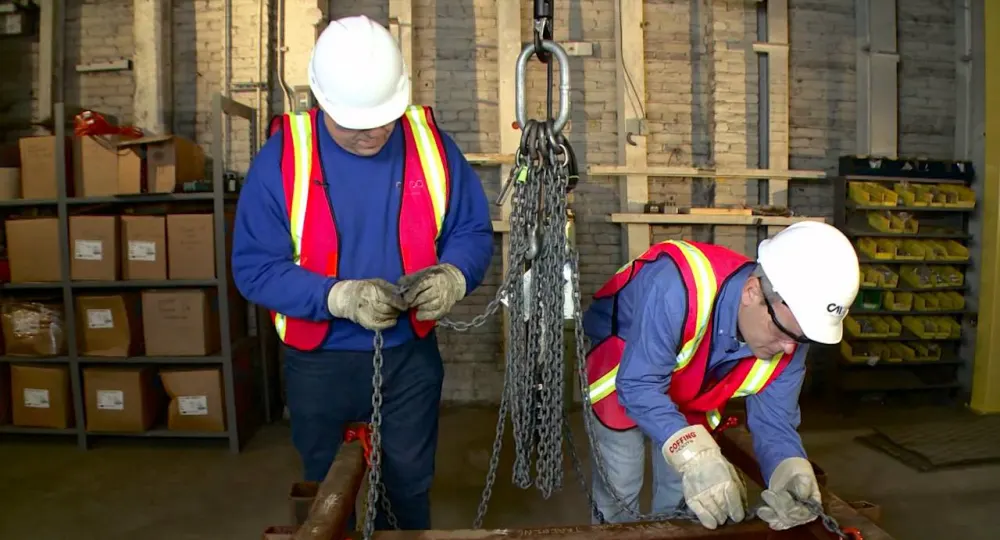

You encounter many types of rigging equipment in material handling. Each component plays a unique role in safe and efficient lifting. Understanding these categories helps you select the right tools for your application and ensures compliance with safety standards.

Slings and Synthetic Slings

Slings serve as the primary connection between your load and the lifting device. You can choose from several types of slings, including wire rope slings, chain slings, and synthetic slings. Wire rope slings offer high tensile strength and flexibility, making them suitable for a wide range of lifting tasks.

Chain slings excel in heavy lifting due to their exceptional durability and load capacity. Synthetic slings, made from polyester or nylon, provide lightweight handling and resistance to certain chemicals, which is ideal for delicate or finished surfaces.

Tip: Always match the sling’s working load limit to your load’s weight and consider the environment. For example, synthetic slings work well in non-abrasive, non-corrosive settings, while chain slings handle rugged conditions.

Powerful Machinery manufactures all types of slings to meet Grade 80 and Grade 100 standards. Each sling comes with clear load markings and full traceability, supporting your compliance and inspection routines.

Shackles and Connectors

Shackles and connectors link different pieces of rigging equipment, forming a secure lifting system. You find screw pin, bolt-type, and round pin shackles, each designed for specific lifting scenarios. Shackles must undergo inspection before every use.

You should always ensure the pin is properly seated and secured to maintain the shackle’s strength.

Powerful Machinery’s shackles and connectors are produced in strict accordance with international standards. You receive full material traceability and certification, which simplifies project sign-offs and safety audits.

Hooks and Hoist Rings

Hooks attach slings or chains to the load or lifting device. You can select from various hook types, such as grab hooks, slip hooks, and self-locking hooks. Hoist rings provide a secure lifting point on machinery or equipment, allowing for rotation and angular lifts without compromising safety.

You must always check that hooks and hoist rings match the load requirements and are free from damage. Powerful Machinery offers hooks and hoist rings with certified strength and clear load ratings, ensuring safe and reliable lifting operations.

Wire Ropes and Chains

Wire ropes and chains form the backbone of many lifting devices. Wire ropes consist of multiple strands of high-grade steel wires, offering high tensile strength and flexibility. Chains, made from interlocking metal links, provide exceptional strength for heavy lifting and demanding environments.

Feature | Wire Rope | Chain |

|---|---|---|

Construction | Multiple strands of high-grade steel wires | Interlocking metal links |

Tensile Strength | High tensile strength and flexibility | Exceptional strength for heavy loads |

Durability | Performs well under various conditions | Handles heavier loads with ease |

You should select wire ropes for applications requiring flexibility and chains for the heaviest loads. Powerful Machinery’s wire ropes and chains are manufactured to Grade 80 and Grade 100 standards, supporting your need for certified, traceable, and compliant rigging.

Pulleys, Blocks, and Sheaves

Pulleys, blocks, and sheaves multiply lifting force and redirect loads. You use block and tackle systems for heavy-duty lifting in cranes, winches, and hoists. Snatch blocks and cable blocks help with load redirection and pulling operations in construction, shipping, and logistics.

Pulley blocks are common in shipping yards, construction sites, and manufacturing facilities.

They facilitate hoisting heavy machinery and materials, improving efficiency and safety.

Powerful Machinery supplies a full range of pulleys, blocks, and sheaves, each designed for durability and compliance with industry standards.

Eyebolts, Eye Nuts, and Turnbuckles

Eyebolts and eye nuts create secure attachment points for lifting. Turnbuckles adjust tension in rigging systems, ensuring loads remain stable and secure. You must always select proof-tested hardware, inspect after testing, and never exceed the rated load.

Manufacturer markings, size, and grade must be visible for compliance.

Turnbuckle threads must be fully engaged.

Avoid side loading and ensure all loads are in line and under tension.

Powerful Machinery’s eyebolts, eye nuts, and turnbuckles meet strict compliance requirements. Each piece is marked for traceability and rated for safety.

Spreader Bars and Lifting Beams

Spreader bars and lifting beams enhance load stability during material handling. Spreader beams distribute compressive stress, making them ideal for wide and heavy loads. This design prevents tipping or shifting by evenly distributing weight.

Lifting beams manage bending stress and work well for lighter loads or when you need precise load positioning.

You should use spreader beams for high-capacity lifts and wide loads, especially in outdoor settings with ample headroom. Lifting beams are better for indoor environments with limited space and single-point attachments.

Powerful Machinery engineers both spreader bars and lifting beams for certified strength, traceability, and compliance. You can rely on these lifting devices for safe, stable, and efficient operations.

Note: Always match the type of rigging equipment to your specific lifting task. Consider load weight, environment, and lifting angle to ensure safety and efficiency.

Powerful Machinery’s Commitment to Quality

You benefit from Powerful Machinery’s dedication to certified strength, standards readiness, and full traceability. Every product supports your compliance needs and reduces risk during inspections.

You can trust that each component is manufactured to meet or exceed international standards, providing confidence for every lift.

Manufactured in strict accordance with ASME, EN, and other major standards

Full material traceability and certification for safety audits

Grade 80 and Grade 100 products for consistent jobsite acceptance

By understanding the types of rigging equipment and their applications, you make informed decisions that protect your team and improve operational efficiency.

How to Choose Rigging Equipment?

Assessing Load and Application

You must start every rigging project by evaluating the load. Accurate assessment ensures safe lifting and efficient load handling. Use these steps to select the right rigging equipment:

Determine the load weight from equipment nameplates, shipping documents, or engineering blueprints.

If direct information is unavailable, calculate the load volume and multiply by material density.

Select rigging equipment such as hoists, winches, slings, shackles, and spreaders based on the load’s weight and type.

You should match the rigging gear to the lifting requirements. Heavy machinery demands high-strength chains and wire ropes. Delicate loads may require synthetic slings for gentle lifting. Proper selection reduces risk during rigging operations and supports safe load handling.

Environmental and Safety Considerations

Environmental factors play a major role in rigging operations. Temperature changes affect sling performance. High heat can cause wire rope lubricants to evaporate and synthetic fibers to lose strength. Cold temperatures may make steel brittle and synthetic slings stiff, increasing the risk of cracking.

Always check the temperature ratings provided by the manufacturer.

Steel chain slings withstand temperatures up to 600º F. Synthetic slings work best between –40º F and 180º F. Humidity, especially in saltwater environments, increases corrosion risk. Stainless steel rigging tools offer better resistance in these conditions.

You must select materials that suit your job site’s climate to ensure safe lifting.

Standards and Certifications

You need to verify that all rigging equipment meets international standards. Certifications such as NCCCO and ISO 9001 confirm that rigging companies follow strict safety and quality protocols. These certifications validate operator skills and demonstrate a commitment to safe rigging operations.

Certification | Description | Standards Aligned |

|---|---|---|

NCCCO | Validates qualified crane and rigging operators through rigorous testing. | OSHA, ASME, ANSI |

ISO 9001 | Ensures quality management in rigging operations. | N/A |

ISO 45001 | Focuses on occupational health and safety management. | N/A |

You should look for equipment that aligns with OSHA, ASME, and ANSI standards. Training in core rigging knowledge, hands-on practice, and real-world scenarios improves safety and efficiency in lifting.

Tip: Standards differ by region. In the United States, you see advanced technology and high-strength steel wire ropes. Europe emphasizes craftsmanship and eco-friendly practices. Asia focuses on efficiency and automation in rigging operations.

Why Choose Powerful Machinery?

You gain several advantages by choosing Powerful Machinery for your rigging needs.

Feature | Powerful Machinery | Competitors |

|---|---|---|

Certification | Products meet or exceed international safety standards | Varies by manufacturer |

Quality Control | Strict inspection and testing before shipping | May not have rigorous testing |

Manufacturing Model | Direct manufacturing for lower costs and faster delivery | Often involves middlemen |

Custom Solutions | Custom lifting solutions available | Limited customization options |

Powerful Machinery delivers certified rigging equipment for lifting and load handling. You benefit from strict quality control, full traceability, and custom solutions for complex rigging operations. Direct manufacturing ensures reliable delivery and competitive pricing.

You can trust Powerful Machinery to support safe and efficient lifting across all industries.

Rigging Equipment Safety and Inspection

Inspection Routines and Frequency

You must inspect rigging before every shift and after any incident that could affect its integrity. Regular rigging inspection helps you catch problems early and prevent failures during lifting operations. The frequency of rigging gear inspection depends on service conditions. Use the table below to guide your schedule:

Service Type | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified person |

You should always follow OSHA requirements and your company’s health and safety regulations. In the USA, OSHA mandates compliance with the ASME B30 standard. In Saudi Arabia, SASO requires both initial and periodic inspections by accredited bodies.

Never skip pre-use checks for slings, hooks, shackles, and all rigging gear.

Common Safety Practices

You can reduce accidents in lifting operations by following proven safety protocols. Here are the most effective practices:

Conduct pre-use inspections for all slings, shackles, hooks, and lifting hardware.

Use standardized hand signals or radio communication.

Calculate load weights before every lift.

Check the Working Load Limit (WLL) of all rigging equipment.

Follow recommended sling angle guidelines (45°–60°).

Store rigging equipment properly to prevent corrosion and damage.

You must also watch for common causes of failure, such as improper installations, overload, damaged slings, and stretched or bent links. Consistent attention to these details keeps your lifting operations safe and compliant with OSHA.

Implementing a Safety Program

A formal safety program sets clear expectations for everyone involved in rigging. You should train your team on proper rigging inspection, equipment use, and emergency procedures. Regular safety meetings reinforce best practices and keep everyone alert.

Always document inspections and corrective actions. This record-keeping supports compliance with OSHA and other health and safety regulations.

Tip: Assign a qualified person to oversee rigging gear inspection and safety protocols. This step ensures accountability and helps you maintain high standards.

Traceability and Compliance with Powerful Machinery

You gain a major advantage with Powerful Machinery’s traceable rigging products. Traceability lets you track every component from production to the job site. This system helps you quickly identify and isolate any defective items, protecting your team and your reputation.

You can prove compliance with safety standards during audits, which helps you avoid legal penalties and maintain certifications.

Traceability ensures consistent quality and supports early detection of issues.

Detailed records make it easy to show adherence to OSHA and international standards.

Real-time monitoring allows you to take corrective action before problems escalate.

You can trust Powerful Machinery to support your lifting operations with certified, traceable rigging that meets the highest safety standards.

Types of Rigging and Their Applications

Lifting, Securing, and Mooring

You encounter several types of rigging in material handling. Each type serves a specific purpose and helps you achieve safe and efficient lifting. You use lifting rigging to move loads vertically, securing rigging to stabilize and hold items in place, and mooring rigging to anchor equipment or vessels.

Blocks and pulleys allow you to lift heavy loads with less effort. You use snatch blocks and swivel blocks for different lifting angles.

Eye bolts create anchor points for rigging. You select the right type for each lifting need.

Rigging hooks come in many shapes and sizes. You rely on them for hoisting and securing loads during lifting operations.

Wire ropes and accessories form the backbone of lifting and mooring. Stainless steel wire ropes offer strength and flexibility for demanding tasks.

Stainless steel nuts connect and secure rigging hardware. You choose corrosion-resistant types for marine and outdoor environments.

You must consider load requirements for each application. Uplift forces affect structures submerged in water, while concentrated loads from cranes and trucks require strong rigging. Uniform and concentrated live loads matter for crane tracks and deck slabs.

Horizontal loads play a role in piers and wharves, especially during berthing. Mooring loads depend on wind, current, and wave direction. You often use computer simulations to analyze these forces and select the right types of rigging.

Tip: Always match the types of rigging to your specific lifting, securing, or mooring task. Powerful Machinery offers certified solutions for every application, ensuring safety and reliability.

Industry-Specific Uses

You find specialized rigging applications across industries. Each sector demands unique solutions for lifting and material handling.

Industry | Application | Key Considerations |

|---|---|---|

Oil and Gas | Transporting materials and equipment to offshore platforms using cranes. | Skilled riggers work under extreme conditions. |

Manufacturing | Moving and installing heavy machinery in production lines. | Precision alignment prevents equipment damage. |

Construction | Erecting buildings and infrastructure using cranes and hoists. | Safety and load balancing are paramount. |

In oil and gas, you use rigging for transporting and installing rigs and pipelines. Powerful Machinery supplies wire ropes and hooks designed for offshore lifting.

Manufacturing relies on rigging to move production line machinery. You need precise lifting and securing to avoid costly errors.

Construction uses rigging for heavy lifting of steel beams, concrete panels, and equipment. You depend on spreader bars, lifting beams, and shackles for safe operations.

You improve safety and efficiency by choosing the right types of rigging for each industry. Powerful Machinery supports your needs with certified, traceable products built for demanding environments.

Conclusion

You improve operational safety and efficiency when you understand the different types of rigging equipment for material handling. Careful selection based on load, environment, and compliance with standards protects your team and property. Certified and traceable products from Powerful Machinery offer benefits such as:

Compliance with international certifications and full material traceability.

Increased productivity, reliability, and durability for lifting operations.

Regular inspection prevents hazards, extends equipment life, and ensures safe workflow. Make safety your top priority in every material handling project.

FAQ

What is rigging equipment used for?

You use rigging equipment to lift, move, secure, or stabilize heavy loads in construction, manufacturing, and marine industries. Each component helps you control loads safely and efficiently.

How often should you inspect rigging equipment?

You should inspect rigging equipment before every use. Schedule regular, detailed inspections based on service conditions. Follow your company’s safety guidelines and industry standards for best results.

How do you choose the right rigging equipment?

You assess the load’s weight, shape, and environment. Select equipment with the correct working load limit and certifications. Always match the tool to your specific lifting task.

Why is traceability important in rigging equipment?

Traceability lets you track each component from production to job site. You can quickly identify issues, prove compliance during audits, and ensure only certified equipment enters your workflow.

Can you use different types of slings together?

You should not mix different sling types in one lift. Always use slings with matching materials, ratings, and certifications to maintain safety and compliance.