Rigging safety involves applying key safety principles and protocols to control and move heavy loads safely. You play a vital role in keeping job site safety high, as improper rigging can lead to serious injuries or even fatalities.

In construction and manufacturing, over 2.6 million nonfatal injuries were reported in 2023, with 60% of crane-related fatalities linked to rigging failures. The right certified equipment, such as that from Powerful Machinery, helps you prevent these incidents and ensures compliance with strict industry standards.

Evidence Type | Statistic |

|---|---|

Nonfatal Workplace Injuries | Over 2.6 million (2023) |

Percentage of Crane-Related Fatalities from Rigging Failures | 60% |

Average Cost of Workplace Injury | $43,000 |

Key Takeaways

Always inspect rigging equipment before use to catch any damage or wear. This simple step can prevent serious accidents.

Understand the roles of operators, riggers, and signal personnel. Clear communication and defined responsibilities enhance safety on the job site.

Use certified rigging equipment from trusted suppliers like Powerful Machinery. This ensures compliance with safety standards and reduces risks during lifts.

Plan every lift carefully, considering load weight, center of gravity, and environmental conditions. Proper planning helps avoid accidents and ensures smooth operations.

Regular training and ongoing education are essential. Keeping skills updated helps workers stay safe and aware of the latest safety practices.

Rigging Safety Roles and Responsibilities

Operators, Riggers, and Signal Personnel

You must understand the distinct roles in rigging to maintain a safe work environment. Operators control the machinery and execute lifts. Riggers attach loads, inspect equipment, and ensure secure connections. Signal personnel communicate instructions and guide lifts, especially when visibility is limited.

When each person knows their responsibilities, you reduce confusion and prevent accidents.

Trained signal personnel give clear signals, which helps you avoid mistakes during crane lifts.

Standardized communication protocols from signalmen make sure everyone understands commands, lowering the risk of miscommunication.

Safety-focused riggers and signalmen encourage a culture of safety, so all workers feel responsible for preventing accidents.

Clear role assignments in rigging operations help you coordinate tasks efficiently. You can trust that everyone knows what to do, which keeps the job site organized and safe.

Employer and Worker Duties

Employers must provide certified rigging equipment and proper training. You need access to products that meet industry standards, like those from Powerful Machinery. Employers should inspect equipment regularly and maintain records for compliance.

You must follow safety procedures, report hazards, and use equipment as intended.

Workers have a duty to check rigging hardware before each use. You should never exceed load limits or ignore warning signs. If you see damaged gear, report it immediately. Employers must support you by offering ongoing education and up-to-date safety information.

Tip: Using certified products from Powerful Machinery ensures you meet safety requirements and reduces risk on every lift.

When you and your team understand your roles and duties, you create a safer workplace. Reliable equipment and clear communication form the foundation of successful rigging.

Rigging Safety Principles and Hazards

What Is Rigging Safety?

Rigging safety means using the right methods and equipment to move heavy loads without causing harm. You must follow strict rules to protect yourself and your team during rigging operations.

Leading safety organizations agree that you need to define employee roles, identify hazards, and complete proper training before you start any rigging task. When you understand these core principles, you lower the risk of accidents and keep your workplace safe.

Employee roles: Operators, riggers, and signal personnel each have clear duties.

Hazard identification: You must spot dangers before lifting begins.

Training requirements: Everyone involved in rigging needs up-to-date training.

Safety Factors in Rigging

You must always consider safety factors when planning a lift. Safety factors help you choose the right equipment and prevent failures. Powerful Machinery designs every product with certified safety factors, so you can trust the strength and reliability of your rigging hardware.

Each component comes with a clear load rating, making it easy for you to select the right gear for your job.

Load balance and center of gravity: You need to align loads properly to avoid tilting.

Sling angles: The angle of your slings affects the stress on your rigging.

Dynamic forces: Loads in motion create extra forces you must control.

Load rating and capacity: Never exceed the rated capacity of your rigging equipment.

Load securing: Use the correct method for each type of material.

Tip: Always check the load rating on your rigging hardware before starting any lift.

Common Hazards in Lifting

You face many hazards during lifting operations. Some of the most common include:

Inadequate pre-use inspections—using damaged rigging can cause accidents.

Lack of communication and coordination—misunderstandings can lead to mistakes.

Poor load control—unstable loads may shift or tip over.

Overloading rigging equipment—exceeding limits can cause equipment failure.

Incorrect sling angles—low angles increase tension and risk.

Improper storage of rigging equipment—exposure to harsh conditions weakens gear.

Electrical hazard from power lines—contact can result in severe injury or death.

You can avoid many of these hazards by following rigging safety rules, using certified equipment from Powerful Machinery, and staying alert during every lift.

Rigging Hardware and Equipment for Lifting

Types of Rigging Hardware

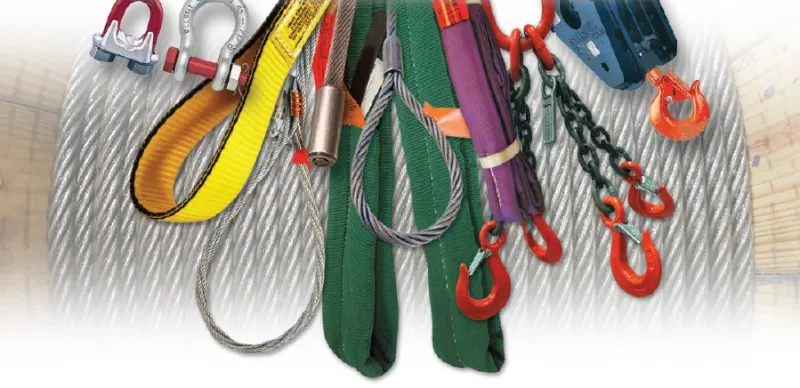

You need the right rigging hardware to ensure every lift is safe and efficient. Powerful Machinery offers a complete range of products designed for construction and manufacturing. You will find these types of rigging hardware most often on job sites:

Shackles: You use these to connect slings, hooks, or other hardware. They come in screw-pin and bolt-pin types.

Turnbuckles: You adjust sling length and tension with these, which helps balance loads.

Swivel Hoist Rings: You rely on these for dynamic loads because they rotate freely.

Master Links: You connect multiple slings for complex lifts.

Hooks: You use these in nearly every crane operation.

Each piece of hardware plays a unique role in rigging safety. You must select the right component for your specific lifting task.

Equipment Selection and Load Ratings

You must always match your rigging equipment to the load and lifting conditions. Powerful Machinery provides hardware with clear load ratings, so you can quickly check if the gear meets your needs. You should never exceed the rated capacity. Load testing is essential for rigging safety.

Qualified professionals inspect and test all equipment at 100% to 150% of its rated load before it reaches you. This process helps you avoid weak points and prevents failures.

Tip: Always review the load rating and inspection documentation before using any rigging hardware.

Powerful Machinery Product Standards

You can trust Powerful Machinery to deliver certified, traceable rigging hardware. Every product meets or exceeds industry standards, including Grade 80 and Grade 100 requirements. You receive equipment with full load testing and inspection records.

Certified professionals perform all inspections, and you get documentation for your records. This commitment to compliance supports your rigging safety program and helps you meet regulations like 29 CFR 1910.179.

Key Points | Details |

|---|---|

Regulation | 29 CFR 1910.179 |

Test Load Limits | Max 125% of rated capacity |

When Testing Is Required | New cranes, after repairs or modifications |

Documentation | Keep test reports for the crane’s lifespan |

Importance of Load Testing | Identifies weak points, prevents failures |

Compliance | Regular inspections and recordkeeping |

You improve job site safety and efficiency when you choose hardware that is certified, traceable, and built for demanding environments.

Routine Inspections and Maintenance

Routine inspections form the backbone of rigging safety. You must check your rigging equipment regularly to prevent accidents and keep your team safe. Powerful Machinery supports you with traceable products that make every inspection and compliance check easier.

Pre-Use and Daily Checks

You should start each shift with a pre-use inspection. Look for worn or damaged gear before you begin any lift. Check for cracks, bent parts, or missing labels. If you find any problems, remove the equipment from service right away. This habit helps you catch issues early and avoid costly mistakes.

Tip: Always inspect your rigging hardware before every use. A few minutes can prevent serious accidents.

Periodic and Post-Incident Inspections

You need to schedule regular inspection intervals based on how often you use your rigging and the conditions on your job site. OSHA and ASME require documented inspections at least every 12 months. If you work in harsh environments or use your equipment heavily, you may need to inspect it monthly or quarterly.

After any incident or overload, perform a detailed inspection before using the gear again.

Consider these factors for inspection frequency:

How often do you use the equipment

The severity of service conditions

The type of load-handling activities

Your experience with similar gear

Traceable rigging from Powerful Machinery lets you log every inspection and repair, so you never miss a step.

Inspection Checklists

A checklist helps you stay organized during routine inspections. You should include these steps:

Examine all hooks, shackles, and slings for cracks or deformation.

Check for missing identification tags or unreadable markings.

Inspect wire ropes for broken wires or kinks.

Review the maintenance history using traceable records.

Document every finding for future audits.

Accurate logging supports compliance and keeps your rigging safety program strong. With Powerful Machinery’s traceable products, you can easily track maintenance and pass audits with confidence.

Planning, Hazard Identification, and Communication

Lift Planning and Load Routes

You must approach every lift with proper planning. Before any lifting operations, you need to develop a detailed lift plan. This plan should include the load weight, center of gravity, rigging equipment specifications, crane type, and site layout. You also need to review the sequence of operations and conduct a risk assessment.

Develop an engineered lift plan that covers all technical details.

Choose equipment that matches the load and site conditions.

Use certified rigging hardware and check sling angles.

Perform a dry run to test the lift sequence and clearances.

Assign a lift director and establish clear communication protocols.

Monitor weather and ground conditions for added safety.

Execute the lift with patience and precision.

Review the operation after completion to identify improvements.

You should always evaluate site access, overhead obstructions, and team roles. Hold pre-lift meetings to discuss hazards and verify equipment. Document every step to ensure accountability.

Hazard Identification and Control

Identifying hazards is a critical part of rigging safety. You need to inspect the site for risks such as overhead power lines, unstable ground, or nearby traffic. Use systematic checklists to prevent oversight. Assess the complexity of the lift and gather accurate load information.

If you spot a hazard, control it before starting the lift. Adapt your plan if conditions change. This proactive approach keeps your team safe and reduces the chance of accidents.

Tip: Always update your risk assessment as new hazards appear during lifting operations.

Communication Methods

Clear communication is essential for safe rigging. Assign one person to signal the crane operator. Use standard hand signals, radios, or verbal instructions. Confirm that everyone understands the signals before you begin. Maintain eye contact or a clear line of sight whenever possible.

If you notice confusion or a problem, stop the lift immediately. International standards recommend continuous communication between the operator and the signalperson. You should always report changes or unexpected issues right away.

Communication Method | Best Practice |

|---|---|

Hand Signals | Use standard, agreed-upon gestures |

Radios | Keep messages brief and clear |

Verbal | Confirm instructions before action |

Strong teamwork and communication help you manage risks and keep lifting operations safe.

Safe Lifting and Rigging Practices

Basic Rigging Safety Rules

You must follow clear rules to keep every lift safe. Always inspect your rigging equipment before use. Never use damaged or uncertified gear. Check that all hardware, such as shackles and hooks, matches the load requirements. Do not exceed the rated capacity of any component.

Keep your work area clean and free of obstacles. Communicate with your team before and during each lift. Stop the operation if you see any unsafe conditions.

Remember: Using certified rigging hardware from Powerful Machinery helps you meet safety standards and reduces risk on every job.

Follow these best practices to maintain safe rigging operations:

Inspect all equipment before and after each use.

Use only certified and traceable rigging products.

Confirm load weights and lifting points.

Assign clear roles to each team member.

Maintain proper documentation for every lift.

Proper Techniques and Sling Angles

You need to use the right techniques to keep loads stable and prevent accidents. Always attach slings securely and avoid sharp edges that can damage them. Use padding or protection where needed. Position the load so the center of gravity stays directly under the hook. Lift slowly and steadily to avoid sudden movements.

Sling angles play a critical role in rigging safety. The angle of loading, as described by OSHA, is the inclination of a sling’s leg measured from the horizontal or vertical plane. As the angle decreases from horizontal, the tension on the sling increases. For example, a 60° angle is safer than a 45° angle.

Angles below 30° can multiply forces to dangerous levels and should only be used after an engineering review. When you keep sling angles at 60° or greater, you reduce stress on the sling and improve load stability. Understanding sling angles is essential for ensuring the safety of personnel and the stability of the lifted load.

Powerful Machinery’s rigging equipment comes with clear load ratings and is designed to support proper rigging techniques. You can trust these products to help you achieve safe and efficient lifting.

Load Handling and Area Security

You must secure the area before and during any lifting operation. This protects both workers and bystanders from hazards. Document your process to create a clear roadmap for everyone involved. Conduct regular training sessions to keep your team aware of security threats and proper load handling procedures.

Build strong relationships with reliable partners and verify their credentials. Take detailed photos of each load before transport to confirm its condition and security. Secure dockboards to prevent accidents.

Use appropriate equipment, such as forklifts and pallet jacks, that are inspected and maintained.

Train workers on safe loading and unloading procedures.

Secure the load with straps, chains, or other devices to keep it stable during transport.

Follow established loading and unloading procedures to prevent injuries and damage.

Powerful Machinery’s certified rigging hardware and equipment help you maintain area security and control during every lift.

Personal Protective Equipment (PPE)

You must wear the right personal protective equipment for every rigging task. PPE protects you from falling objects, pinch points, and other hazards. Standard PPE includes hard hats, safety glasses, gloves, steel-toed boots, and high-visibility vests. In some cases, you may need hearing protection or respiratory gear.

Check your PPE before each use. Replace any damaged or worn items immediately. Make sure your gear fits properly and does not restrict movement. Encourage your team to use PPE at all times during rigging operations.

Tip: Consistent use of PPE, combined with certified rigging equipment from Powerful Machinery, forms the foundation of safe rigging best practices.

By following these practices, you create a safer work environment and reduce the risk of accidents. Rely on certified products and proven procedures to support every lift.

Training and Safety Culture

Rigging Safety Training Requirements

You need proper training to work safely in rigging operations. OSHA and other regulatory bodies set clear requirements for rigging safety. You must complete formal training or on-the-job instruction that covers safe rigging practices. You need to understand how to rig loads safely and show your skills in real situations.

Your employer decides if you are qualified for specific tasks, but you must always follow OSHA’s rigging standards, including 29 CFR 1926.251.

Complete formal training or on-the-job instruction.

Learn how to rig loads safely.

Demonstrate your ability to perform rigging tasks.

Meet your employer’s qualification standards.

Follow OSHA’s rigging safety regulations.

Powerful Machinery supports your training by providing certified equipment and clear documentation, making it easier for you to meet compliance standards.

Ongoing Education and Certification

Proper training does not end after your first class. You need ongoing education to keep up with new safety protocols and best practices. Regular updates help you understand changes in regulations and improve your technical skills.

Certification programs give you credentials that show your commitment to safety and can help you advance in your career.

Ongoing education fills knowledge gaps and helps you calculate load capacities.

It reduces human error by giving you the tools to make smart decisions.

Certification programs prove your skills and dedication to rigging safety.

Powerful Machinery encourages you to pursue ongoing education and offers support for industry-recognized certification.

Building a Safety Culture

A strong safety culture starts with proper training and clear safety policies. You need to assess risks, use personal protective equipment, and inspect your equipment regularly. Job-specific procedures and checklists help you stay organized.

Good communication keeps everyone informed. Emergency response plans prepare you for unexpected events. Continuous improvement ensures your team learns from every job.

A lack of training can lead to accidents and injuries. You protect yourself and your team by making proper training a priority.

You build a safer workplace when you value training, follow procedures, and use certified rigging equipment from Powerful Machinery.

Regulatory Compliance and Standards

OSHA and Industry Regulations

You must follow strict safety regulations to keep your rigging operations compliant and safe. OSHA sets clear rules for construction and manufacturing, with Standard 1926.753 as a key guideline for hoisting and rigging safety.

You need to perform pre-shift inspections on cranes, checking control mechanisms, safety devices, and ground conditions. A qualified rigger must inspect all rigging before each shift. You cannot exceed the rated capacity of your hoisting equipment or rigging, as shown in the manufacturer’s charts.

These safety standards help you prevent accidents and protect your team.

Powerful Machinery supports your compliance efforts by providing products that meet or exceed international safety standards. You receive equipment certified by ISO9001, TUV Rheinland, OSHA, and other major organizations.

Each product comes with clear documentation, making it easier for you to pass inspections and maintain a safe work environment.

Note: Using certified rigging hardware from Powerful Machinery helps you meet safety regulations and avoid costly violations.

Legal and Safety Consequences

If you fail to follow safety regulations, you face serious consequences. Non-compliance can lead to immediate project shutdowns, causing financial losses and damaging your reputation. You increase the risk of accidents and injuries, which can result in liability issues.

Insurance companies may deny claims if you do not meet safety standards, leaving your business exposed. Your reputation with clients and stakeholders can suffer, making it harder to win future projects. OSHA can also issue fines up to $16,000 per violation.

You protect your business and your team by following all rigging safety regulations and choosing certified equipment. Powerful Machinery’s commitment to international certifications gives you confidence that your rigging meets the highest safety standards.

Environmental and Operational Hazards

Power Lines and Electrical Risks

You face serious risks when working near power lines during lifting operations. Electrical hazards can cause severe injuries or fatalities if you do not take proper precautions. Always plan your rigging so that neither the load nor the rigging lines come close to energized lines. Even a small mistake can have tragic results.

Rigging a branch may be a safer option, but there are still some electrical risks. The cut branch can swing into the overhead power lines if the rigging blocks are above or near the power lines. The rigging line may touch the power line.

Any rigging system must be set so that the rigging lines do not, or the load does not, swing or fall into the power lines. Ground workers have been electrocuted while tending rigging lines when the load contacts a primary.

You should always use certified, non-conductive rigging equipment when possible. Powerful Machinery’s traceable hardware helps you maintain safe distances and ensures compliance with safety standards.

Weather and Environmental Factors

Weather and site conditions can change quickly and create new hazards. You must monitor the environment before and during every lift.

Weather conditions can affect ground stability, visibility, and worker performance, which are critical for rigging safety.

Adverse weather can lead to hazardous situations, increasing the likelihood of accidents.

Operations should be halted in winds exceeding 20 miles per hour, and visibility should be clear for safe crane operation.

High winds can affect load stability and boom control, while rain or snow can make surfaces slippery.

You reduce risks by using equipment from Powerful Machinery that is designed for tough environments and by following strict safety protocols.

Preventing Shock Loading

Shock loading happens when a load is suddenly applied or stopped. This can damage equipment and cause accidents. You must use the right techniques and plan every lift to avoid these dangers.

Use proper rigging techniques to avoid dropping loads.

Train operators and crews to understand the dangers of shock loading.

Inspect equipment regularly for signs of damage.

Follow manufacturer guidelines for rated capacities.

Plan lifts to avoid sudden stops or impacts.

Conduct post-lift inspections to identify wear or damage.

Log and track incidents to build a history for preventative maintenance.

Control rollback by guiding loads slowly back into position.

Promote reporting of unusual rigging behavior to allow for quick corrective measures.

Training your team to stay calm and perform careful inspections strengthens your safety culture. Powerful Machinery’s certified equipment, with clear load ratings and robust construction, helps you prevent shock loading and maintain safe lifting operations.

Technology in Rigging Safety

Modern Inspection Tools

You now have access to advanced inspection tools that transform how you maintain safety on the job site. Digital load monitoring systems give you real-time feedback on load weights and equipment status. These smart sensors help you avoid overloading and ensure balanced lifts.

Wireless inspection devices let you check equipment conditions from a distance, reducing your exposure to hazardous areas. Computer-guided inspection platforms provide detailed reports and maintenance reminders, so you never miss a critical check.

With these tools, you can spot issues early and keep your rigging hardware in top condition.

Powerful Machinery invests in the latest inspection technology. You benefit from traceable products that support digital recordkeeping and compliance. This commitment helps you streamline inspections and maintain a safer workplace.

Innovations in Lifting Operations

Recent innovations have changed how you approach lifting tasks. Smart rigging sensors monitor load parameters and equipment health in real time. Wireless lift control systems allow you to manage operations remotely, improving both safety and efficiency.

Computer-guided equipment gives you instant data for planning and executing complex lifts. High-performance synthetic ropes offer strength and lightweight handling, making your lifts safer and easier. Adjustable spreader beams adapt to different load shapes, giving you more flexibility on the job.

Modern magnetic lifting systems also speed up material handling. You can complete tasks in minutes that once took over an hour. Electro-permanent magnets keep loads secure even during power interruptions and use much less electricity than traditional systems.

These advances lower your operational costs and support sustainability.

Powerful Machinery leads the industry by integrating these innovations into its product line. You gain access to certified, high-quality solutions that keep your operations safe and efficient.

Conclusion

You strengthen rigging safety by following proven best practices:

Use certified equipment and inspect slings before each lift.

Understand working load limits and select the right sling type.

Perform routine pre-use and periodic inspections to catch hazards early.

Train your team regularly to maintain compliance and awareness.

Partnering with certified suppliers like Powerful Machinery helps you create a safer workplace and supports a proactive safety culture.

FAQ

What is the most important step before starting any rigging operation?

You must inspect all rigging equipment before use. Look for damage, wear, or missing labels. This step helps you prevent accidents and ensures your gear meets safety standards.

How often should you inspect rigging hardware?

You should inspect rigging hardware before every use and schedule periodic inspections based on usage and environment. Always document your findings to maintain compliance and safety.

Why should you use certified rigging equipment?

Certified equipment gives you confidence in load ratings and safety factors. You reduce risk and meet industry regulations when you choose certified products from trusted brands like Powerful Machinery.

What should you do if you find damaged rigging gear?

Remove damaged gear from service immediately. Report the issue to your supervisor. Never use equipment that shows signs of wear, cracks, or deformation.

How can you improve communication during lifting operations?

Use standard hand signals, radios, or clear verbal instructions. Assign one person as the signaler. Always confirm that everyone understands the signals before starting the lift.