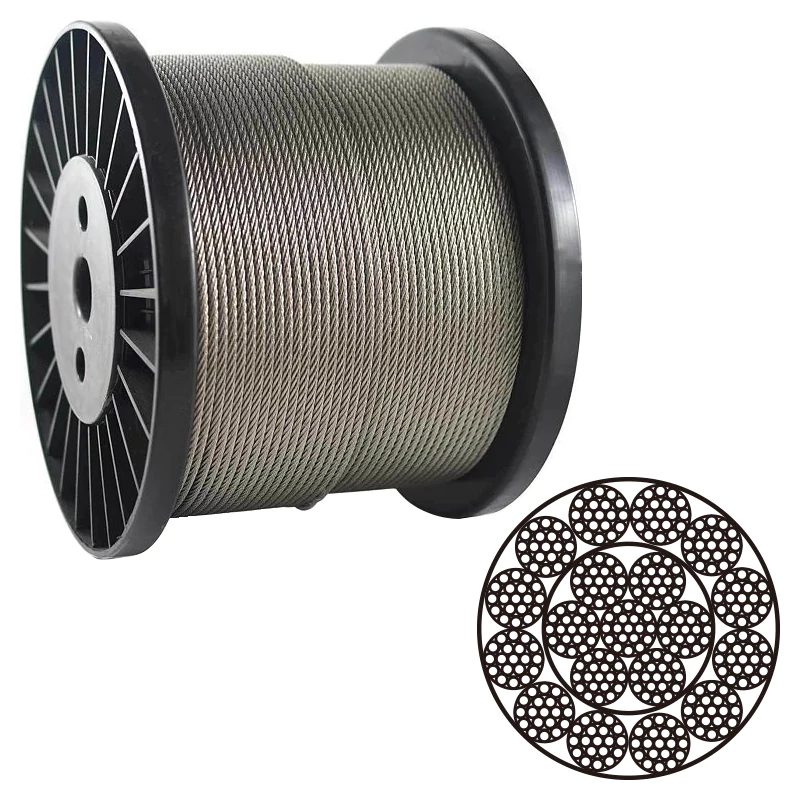

Technical Specifications for 18×19 Non-Rotating Steel Wire Rope

The 18×19 Rotation-Resistant Steel Wire Rope is engineered to provide an optimal blend of stability and durability for modern crane operations. Like all rotation-resistant ropes, it features counter-laid inner and outer strands to generate an internal torque that resists load spin, ensuring safety and precision.

The key advantage of the 18×19 construction lies in its strands, which are composed of 19 finer wires. This design provides significantly greater flexibility and resistance to bending fatigue compared to ropes with fewer wires (like the 18×7), making it the superior choice for applications involving continuous operation over sheaves and drums.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | ||||||||

| MINIMUM BREAKING LOAD OF ROPE | ||||||||||||

| D | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | ||||||||||

| 6 | 14 | 15.5 | 17.5 | 18.5 | 18.6 | 19.7 | 19.8 | 20.9 | 20.9 | 22.1 | 21.9 | 23.1 |

| 7 | 19.1 | 21.1 | 23.8 | 25.2 | 25.4 | 26.8 | 26.9 | 28.4 | 28.4 | 30.1 | 29.8 | 31.5 |

| 8 | 25 | 27.5 | 31.1 | 33 | 33.1 | 35.1 | 35.1 | 37.2 | 37.1 | 39.3 | 38.9 | 41.1 |

| 9 | 31.6 | 34.8 | 39.4 | 41.7 | 41.9 | 44.4 | 44.4 | 47 | 47 | 49.7 | 49.2 | 52.1 |

| 10 | 39 | 43 | 48.7 | 51.5 | 51.8 | 54.8 | 54.9 | 58.1 | 58 | 61.3 | 60.8 | 64.3 |

| 11 | 47.2 | 52 | 58.9 | 62.3 | 62.6 | 66.3 | 66.4 | 70.2 | 70.1 | 74.2 | 73.5 | 77.8 |

| 12 | 56.2 | 61.9 | 70.1 | 74.2 | 74.5 | 78.9 | 79 | 83.6 | 83.5 | 88.3 | 87.5 | 92.6 |

| 13 | 65.9 | 72.7 | 82.3 | 87 | 87.5 | 92.6 | 92.7 | 98.1 | 98 | 104 | 103 | 109 |

| 14 | 76.4 | 84.3 | 95.4 | 101 | 101 | 107 | 108 | 114 | 114 | 120 | 119 | 126 |

| 16 | 99.8 | 110 | 125 | 132 | 133 | 140 | 140 | 149 | 148 | 157 | 156 | 165 |

| 18 | 126 | 139 | 158 | 167 | 168 | 177 | 178 | 188 | 188 | 199 | 197 | 208 |

| 20 | 156 | 172 | 195 | 206 | 207 | 219 | 219 | 232 | 232 | 245 | 243 | 257 |

| 22 | 189 | 208 | 236 | 249 | 251 | 265 | 266 | 281 | 281 | 297 | 294 | 311 |

| 24 | 225 | 248 | 280 | 297 | 298 | 316 | 316 | 334 | 334 | 353 | 350 | 370 |

| 26 | 264 | 291 | 329 | 348 | 350 | 370 | 371 | 392 | 392 | 415 | 411 | 435 |

| 28 | 306 | 337 | 382 | 404 | 406 | 429 | 430 | 455 | 454 | 481 | 476 | 504 |

| 30 | 351 | 387 | 438 | 463 | 466 | 493 | 494 | 523 | 522 | 552 | 547 | 579 |

| 32 | 399 | 440 | 498 | 527 | 530 | 561 | 562 | 594 | 594 | 628 | 622 | 658 |

| 34 | 451 | 497 | 563 | 595 | 598 | 633 | 634 | 671 | 670 | 709 | 702 | 743 |

| 36 | 505 | 557 | 631 | 667 | 671 | 710 | 711 | 752 | 751 | 795 | 787 | 833 |

| 38 | 563 | 621 | 703 | 744 | 748 | 791 | 792 | 838 | 837 | 886 | 877 | 928 |

| 40 | 624 | 688 | 779 | 824 | 828 | 876 | 878 | 929 | 928 | 981 | 972 | 1030 |

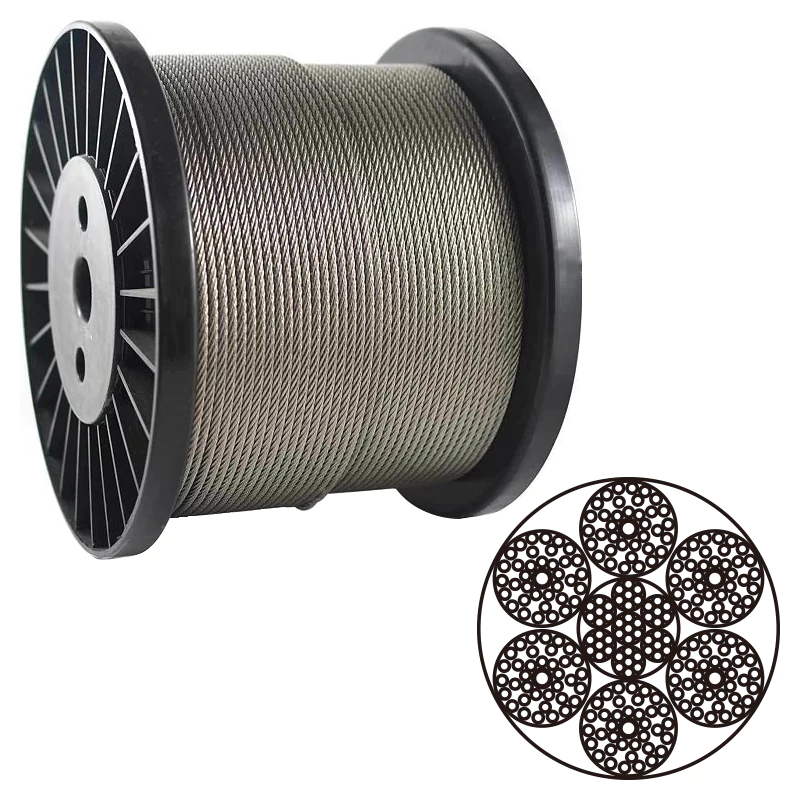

18×19+FC Non-Rotating Steel Wire Rope

This is a special-purpose variant for unique circumstances. By incorporating a fiber core, the rope’s overall flexibility is maximized, making it one of the most pliable rotation-resistant ropes available. This configuration should only be chosen for specific, light-duty applications where the rope must navigate a particularly complex or tight path, and where maximum load capacity and absolute rotational stability are less critical than handling ease.

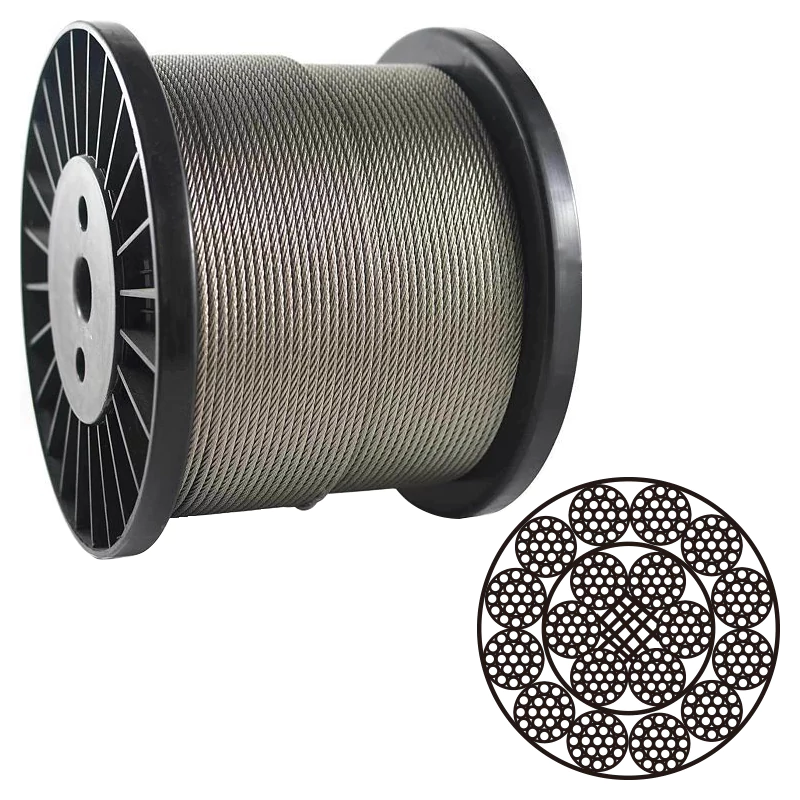

18×19+IWS Non-Rotating Steel Wire Rope

This is the standard, high-performance configuration. It combines the superior flexibility of the 19-wire strands with the strength, crush resistance, and rotational stability provided by the integral steel strand core. This makes it the reliable, go-to choice for the vast majority of single-part hoisting applications that demand both safety and a long operational life.