Technical Specifications for 1×7 Steel Strand

The following table details the technical specifications for our standard range of 1×7 steel strand. Please note that other sizes and grades are available upon request.

| DIAMETER OF STEEL WIRE (MM) | DIAMETER OF STEEL STRAND (MM) | CROSS SECTION OF STEEL STRAND (MM) | GRADE OF NOMINAL STRENGTH (MPA) | |||||

| 1370 | 1470 | 1570 | 1670 | 1770 | REFERENCE WEIGHT (KG/100M) | |||

| MINIMUM BREAKING LOAD (KN) | ||||||||

| 0.13 | 0.4 | 0.093 | 0.117 | 0.125 | 0.134 | 0.143 | 0.151 | 0.082 |

| 0.30 | 0.9 | 0.495 | 0.623 | 0.669 | 0.715 | 0.76 | 0.806 | 0.411 |

| 1.00 | 3.0 | 5.50 | 6.93 | 7.43 | 7.94 | 8.45 | 8.96 | 4.54 |

| 1.20 | 3.6 | 7.92 | 9.98 | 10.71 | 11.44 | 12.16 | 12.90 | 6.59 |

| 1.40 | 4.2 | 10.78 | 13.59 | 14.58 | 15.57 | 16.56 | 17.55 | 8.97 |

| 1.60 | 4.8 | 14.07 | 17.73 | 19.03 | 20.32 | 21.62 | 22.91 | 11.71 |

| 1.80 | 5.4 | 17.81 | 22.45 | 24.09 | 25.72 | 27.36 | 29.00 | 14.83 |

| 2.00 | 6.0 | 21.99 | 27.72 | 29.74 | 31.76 | 33.78 | 35.80 | 18.50 |

| 2.30 | 6.9 | 29.07 | 36.64 | 39.31 | 41.99 | 44.66 | 47.34 | 24.20 |

| 2.60 | 7.8 | 37.16 | 46.82 | 50.24 | 53.66 | 57.08 | 60.50 | 30.93 |

| 3.00 | 9.0 | 49.48 | 62.34 | 66.90 | 71.44 | 75.99 | 80.54 | 41.19 |

| 3.20 | 9.6 | 56.30 | 70.92 | 76.10 | 81.30 | 86.45 | 91.63 | 46.87 |

| 4.23 | 12.7 | 98.33 | 123.94 | 132.98 | 142.03 | 151.07 | 160.12 | 81.95 |

| 5.00 | 15.0 | 137.38 | 173.15 | 185.80 | 198.43 | 211.07 | 223.71 | 114.30 |

| 5.33 | 16.0 | 156.11 | 196.76 | 211.12 | 225.49 | 239.85 | 254.21 | 130.05 |

For custom diameters, different strength grades, or specific coating requirements, please contact our technical sales team.

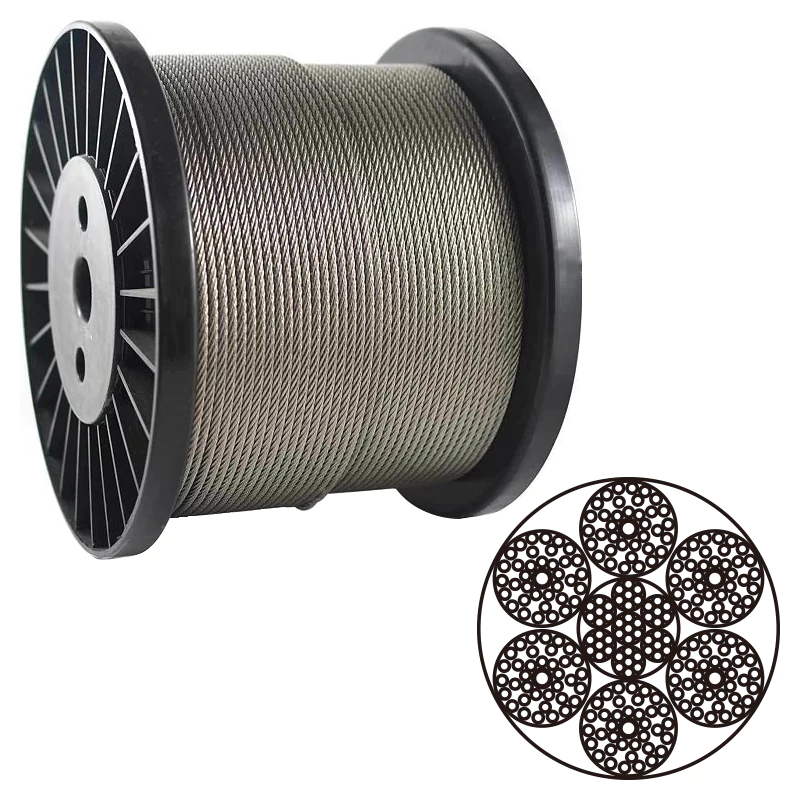

What is 1×7 Steel Strand?

A 1×7 steel strand is a high-strength tension member composed of seven individual high-carbon steel wires that are helically twisted together into a single, tight strand. Unlike more flexible multi-strand wire ropes that are designed for lifting and frequent bending over sheaves, the 1×7 construction creates a semi-rigid cable with exceptionally low stretch and high durability.

This rigidity and minimal elongation under load are its primary engineering advantages, allowing it to maintain consistent and reliable tension over long periods without sagging. As a result, the 1×7 steel strand is the industry standard for static guying, bracing, messenger wire, and structural support applications where strength and stability are the critical requirements.

Features & Benefits of 1×7 Steel Strand

Engineered for Performance and Longevity

We design our 1×7 steel strand to deliver uncompromising performance in the most critical static and guying applications.

High Tensile Strength

Our high-carbon steel construction provides a superior strength-to-diameter ratio, allowing it to securely support immense static loads for critical guying.

Superior Corrosion Resistance

Our 1×7 galvanized steel strand features a thick, hot-dipped zinc coating, providing exceptional protection against rust for a long service life.

Versatile Material & Finish Options

For the most demanding marine or chemical environments, we offer 7 strand stainless steel wire for ultimate defense against aggressive corrosion.

Common Applications of 1×7 Steel Strand

Utility & Telecommunications

As the essential guy wire for supporting utility poles, communication towers, and broadcast antennas, providing the steadfast tension needed to resist wind loads and ensure structural stability.

Structural & Construction

Used as structural support strands in tension fabric buildings, suspension bridges, and for bracing precast concrete panels, providing a strong and efficient method of permanent structural support.

Transportation & Infrastructure

Serves as the high-strength messenger strand that supports overhead power cables for railways, trolleys, and other catenary systems, preventing sag and maintaining proper cable height.

Agriculture & Horticulture

The ideal support cable for creating durable trellis systems in vineyards and orchards, as well as for the structural bracing of large commercial greenhouses against wind and snow loads.

Quality Assurance & Standards

Quality is the foundation of every product we manufacture. Our 1×7 steel strand is produced in facilities that adhere to stringent international standards such as ASTM, ISO, and EN.

From raw material verification to final breaking load tests, our dedicated quality control team monitors every stage of the production process. This rigorous oversight ensures that every strand meets its specified requirements for performance, consistency, and safety.

We provide full material traceability, and Mill Test Certificates (MTCs) are available upon request, giving you complete, documented confidence in the product you receive.

Get a Competitive Quote for Your Project

Ready to equip your project with high-quality steel strand? Send us your requirements—including diameter, strength grade, finish (galvanized or bright), and quantity—and our team will provide a competitive, no-obligation quote promptly.