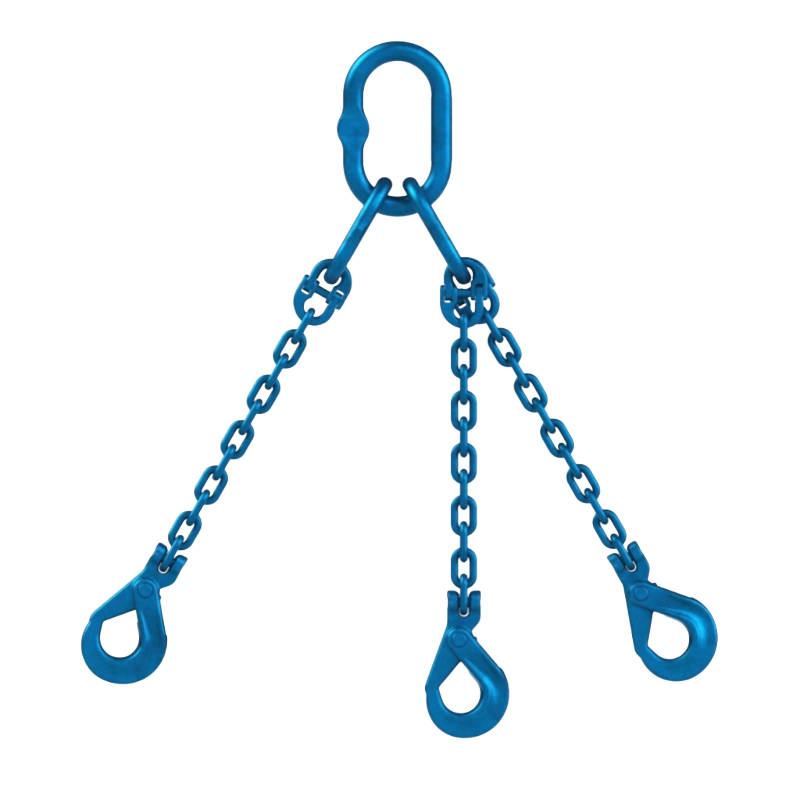

As a trusted chain sling manufacturer of triple leg chain sling, we specialize in providing customized lifting solutions for a wide range of applications, from small to oversized. Our focus is on delivering high-quality chains with strength-enhancing features such as triple alloy (nickel, chromium, molybdenum) and single-weld links for optimal durability and safety.

When ordering your custom 3 leg chain sling or 3 leg adjustable chain lifting sling, please consider the following:

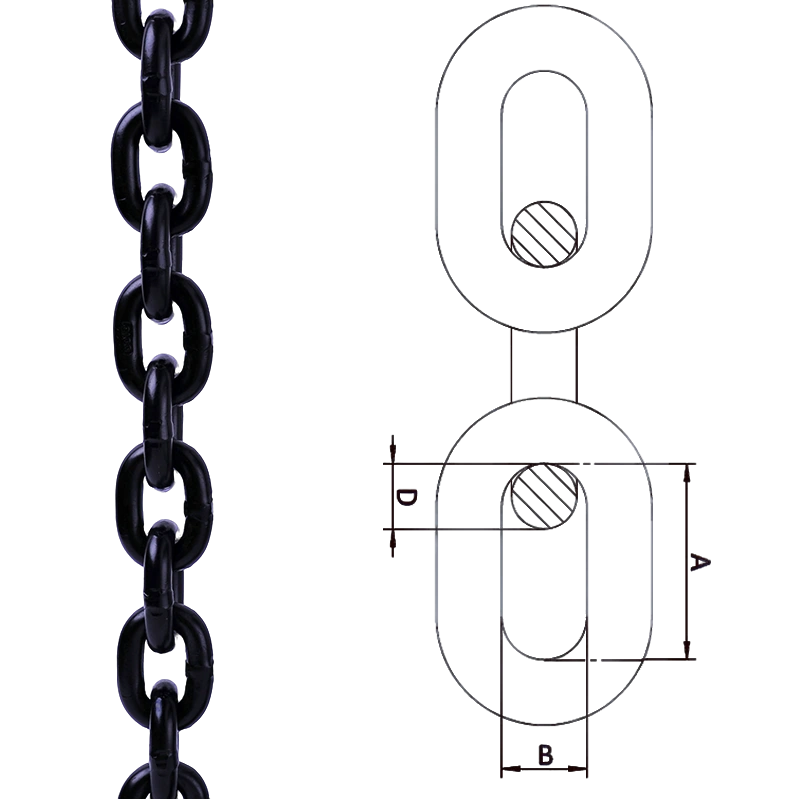

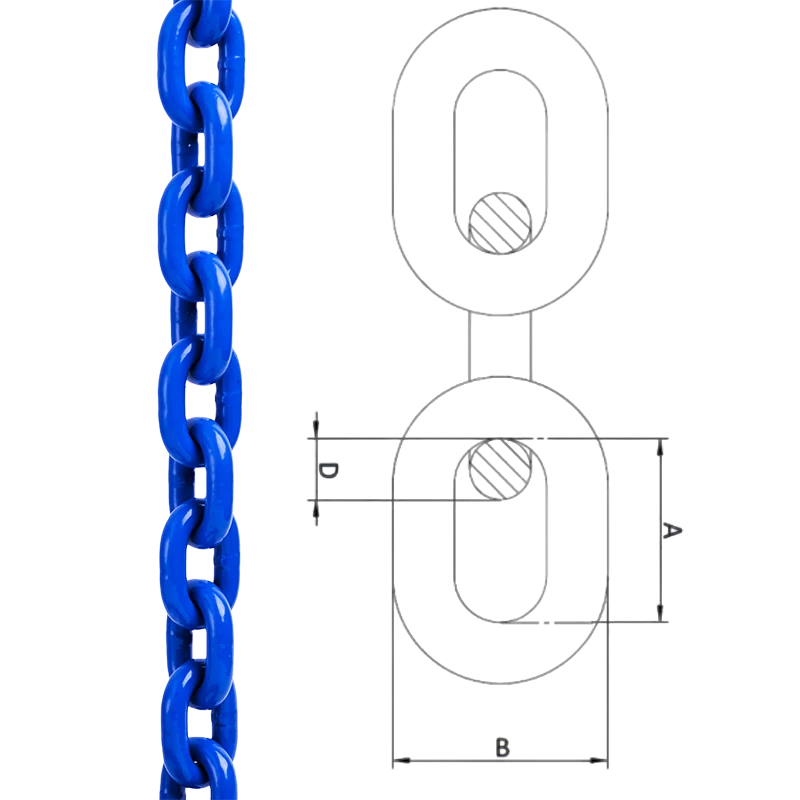

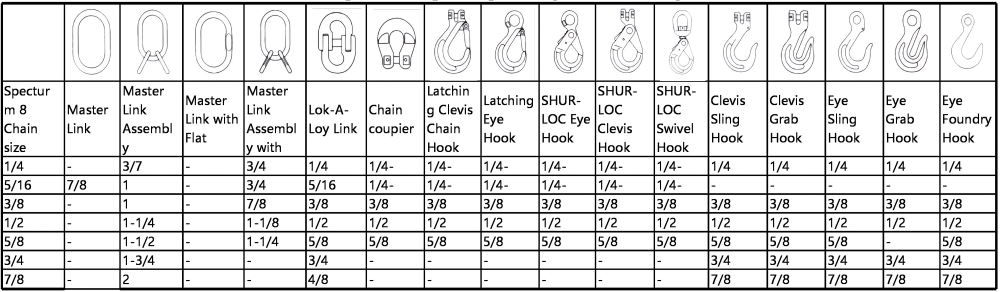

SIZE: Determined by the material size of the chain, based on the required working load limit.

REACH: The length from bearing point to bearing point, including all attachments.

ATTACHMENTS: Standard master links are typically used unless specified otherwise. If you require non-standard master links or hooks, please provide a detailed description or drawing.

TYPE: Specify the correct sling type, such as:

T = Three Leg

A = Adjustable

O = Oblong Link

S = Sling Hook (if required)

These details ensure your 3 legged chain sling is precisely customized to meet your lifting requirements, offering the safety, strength, and performance you need.

DESIGN of TRIPLE LEG CHAIN SLING

GRADE

- 100

FINISH

- Blue Powder Coat Finish

STANDARDS

- Meets or exceeds ASTM A952, NACM, & OSHA 910 Standards

- Safety factor 4:1

- Fatigue Tested at 1.5 times the WLL for 20,000 cycles

- Proof Tested at twice the WLL

HEAT TREATMENT

- Quenched and tempered before proof testing

ORIGIN

- Made in China

LINK TYPE

- Master Link

APPLICATION

- For overhead lifting

- Suited for use with wire rope, chain, and slings

MATERIAL

- Premium Fine Grain Alloy Steel

FAQ of 3 LEGGED CHAIN SLING

What is a triple leg chain sling and why do you choose it instead of two or four legs?

You choose a triple leg chain sling when your load has three lifting points or an uneven center of gravity that requires controlled balance. You achieve greater stability than a two leg sling while avoiding the added weight and higher cost of a four leg assembly. You shorten rigging time because three adjustable legs settle faster on uneven loads. You increase lift safety for steel frames, fabricated modules, pump skids, valves, and structural assemblies.

Advantages you rely on:

• Three-leg geometry limits uncontrolled load rotation

• Adjustable grab hooks allow precise load balancing

• Reduced sling weight improves available crane capacity

• Fewer components simplify inspection and handling

• Well suited for asymmetric and irregular industrial loads

What are chain slings normally used for in industrial lifting operations?

Chain slings serve lifting tasks that require high strength, long service life, and reliable resistance to heat, abrasion, and impact. Industrial operations rely on chain slings for handling steel plates, beams, castings, heavy machinery, offshore equipment, and mining components. Harsh environments favor chain slings because the steel construction tolerates sparks, sharp edges, and extreme temperatures where synthetic slings fail. Repetitive lifting operations select chain slings for consistent performance and strong fatigue resistance.

Common industrial applications:

• Structural steel erection

• Heavy equipment maintenance

• Ship block positioning

• Foundry and forge material handling

• Infrastructure and civil construction projects

How do you calculate the working load limit of a three leg chain sling?

Working load limit calculation for a three leg chain sling depends on sling angle, chain diameter, chain grade, and load symmetry. Equal load sharing across three legs should never be assumed unless lifting points align precisely and remain stable during the lift. Standard industry practice rates most three leg chain slings at two-leg capacity under typical conditions. Angle reduction factors apply to the single-leg working load limit based on the smallest sling angle under tension.

Calculation steps to follow:

• Measure the smallest loaded leg angle

• Apply the correct sling angle reduction factor

• Use the rated capacity for the selected chain grade

• Treat uneven or asymmetric geometry as two-leg loading

• Record calculations for lift planning and compliance audits

How much weight does a triple leg chain sling add to your lift plan?

Sling self-weight must be included in every lift plan because it directly reduces available crane capacity. Triple leg chain slings typically weigh less than four leg assemblies while providing improved load balance compared to two leg configurations. Overall sling weight increases based on chain diameter, total leg length, hook type, and master link size. Risk control depends on selecting an optimized configuration that matches the lift without adding unnecessary mass.

Weight factors to evaluate:

• Chain diameter and grade

• Total leg length

• Hook forging size

• Master link dimensions

• Certification and identification tag hardware

Why do manufacturers rate triple leg chain slings conservatively?

Manufacturers rate triple leg chain slings conservatively because real-world loads shift during lifting. You encounter unequal leg tension due to fabrication tolerances, crane movement, and load flex. Conservative ratings protect your crew and equipment while extending sling service life. You benefit from predictable performance rather than theoretical capacity.

Safety logic you should value:

• Unequal force distribution occurs frequently

• Dynamic lifting changes load paths

• Conservative ratings reduce failure risk

• Compliance simplifies audits and inspections

• Long-term durability improves ownership cost

How do you inspect a 3 leg chain sling before use?

Proper inspection of a 3 leg chain sling before use reduces lifting risk, protects equipment, and supports compliance with industrial safety standards. A consistent inspection routine helps identify wear and damage before a lift begins.

Visual inspection takes place before every lift to identify visible damage or abnormal wear.

Each chain link is checked for deformation, excessive stretch, cracks, gouges, or corrosion that may affect strength.

Hooks are examined for throat opening, twisting, and correct safety latch operation.

Identification tags are reviewed to confirm readability and ensure traceability to rated capacity and certification data.

The sling is removed from service immediately when any defect or nonconformance is found.

Inspection points never skipped:

Chain link deformation or elongation

Surface cracks, sharp nicks, or heavy corrosion

Hook throat spread beyond allowable limits

Missing or damaged safety latches

Illegible or missing identification tags

How long can you expect a triple leg chain sling to last?

Service life depends on usage frequency, load severity, environment, and inspection discipline. You achieve long service life when you avoid overloads and follow inspection rules. Harsh environments like marine, mining, or high-temperature sites shorten lifespan. You extend life through proper storage and component replacement.

Practices that extend sling life:

• Rotate slings across jobs

• Replace hooks before chain wear peaks

• Store slings clean and dry

• Avoid dragging chains on concrete

• Track lift cycles internally