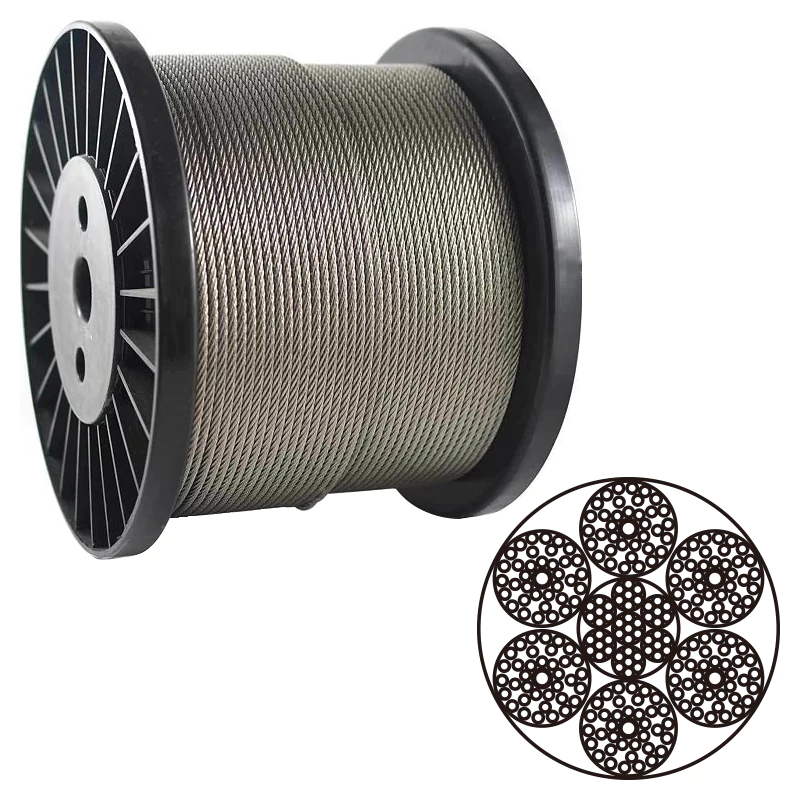

Technical Specifications for 6x19S Steel Wire Rope

The 6x19S classification is a high-performance wire rope designed specifically for applications where abrasion resistance is the most critical factor for service life. Unlike the balanced design of a Warrington rope, the Seale strand pattern features a layer of large, thick wires over a layer of smaller inner wires. This configuration creates a tough, durable outer surface that provides superior protection against wear from drums, sheaves, and contact with the operating environment. While this robust construction is less flexible than other 6×19 types, its longevity in rugged conditions is unmatched.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 5 | 9.2 | 9 | 10.1 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.4 | 16.6 | 16.1 | 17.4 |

| 6 | 13.3 | 13 | 14.6 | 18.7 | 20.1 | 19.8 | 21.4 | 21 | 22.7 | 22.2 | 24 | 23.2 | 25.1 |

| 7 | 18.1 | 17.6 | 19.9 | 25.4 | 27.4 | 27 | 29.1 | 28.6 | 30.9 | 30.2 | 32.6 | 31.7 | 34.2 |

| 8 | 23.6 | 23 | 25.9 | 33.2 | 35.8 | 35.3 | 38 | 37.4 | 40.3 | 39.5 | 42.6 | 41.3 | 44.6 |

| 9 | 29.9 | 29.1 | 32.8 | 42 | 45.3 | 44.6 | 48.2 | 47.3 | 51 | 50 | 53.9 | 52.3 | 56.5 |

| 10 | 36.9 | 36 | 40.5 | 51.8 | 55.9 | 55.1 | 59.5 | 58.4 | 63 | 61.7 | 66.6 | 64.6 | 69.7 |

| 11 | 44.6 | 43.5 | 49.1 | 62.7 | 67.6 | 66.7 | 71.9 | 70.7 | 76.2 | 74.7 | 80.6 | 78.2 | 84.4 |

| 12 | 53.1 | 51.8 | 58.4 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.9 | 93.1 | 100 |

| 13 | 62.3 | 60.8 | 68.5 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 |

| 14 | 72.2 | 70.5 | 79.5 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 126 | 136 |

| 16 | 94.4 | 92.1 | 104 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 165 | 178 |

| 18 | 119 | 117 | 131 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 209 | 226 |

| 20 | 147 | 144 | 162 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 258 | 279 |

| 22 | 178 | 174 | 196 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 313 | 337 |

| 24 | 212 | 207 | 234 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 372 | 402 |

| 26 | 249 | 243 | 274 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 471 |

| 28 | 289 | 282 | 318 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 |

| 30 | 332 | 324 | 365 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 627 |

| 32 | 377 | 369 | 415 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 714 |

| 34 | 426 | 416 | 469 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 747 | 806 |

| 36 | 478 | 466 | 525 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 |

| 38 | 532 | 520 | 585 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 933 | 1007 |

| 40 | 590 | 576 | 649 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1034 | 1116 |

6x19S+FC Steel Wire Rope

This version combines the excellent abrasion resistance of the Seale strands with the flexibility and elasticity of a fiber core. This makes it easier to handle and provides a degree of shock absorption. It is the ideal choice for applications such as draglines, scraper winches, and some logging ropes, where the primary challenge is surface wear, but the full strength of a steel core is not required.

6x19S+IWR Steel Wire Rope

This is the ultimate configuration for durability in the most brutal environments. The solid support of the Independent Wire Rope Core enhances the Seale strands’ inherent strength, providing maximum breaking load and exceptional crush resistance on the drum. This makes it the essential specification for rotary drilling lines, percussion drilling rigs, scrap yard crane ropes, and any heavy-duty application defined by both intense abrasion and high tensile forces.