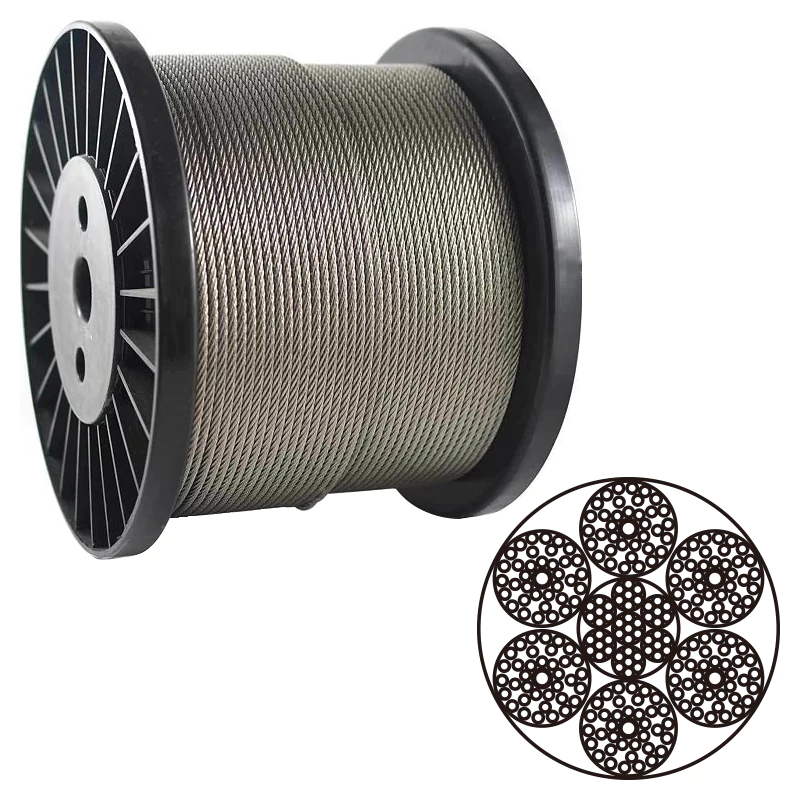

Technical Specifications for 6x19W Steel Wire Rope

The 6×19 Warrington (6x19W) classification is the benchmark for steel wire rope, prized for its versatile design that offers an optimal combination of durability and flexibility. Its unique strand pattern, with alternating thick and thin outer wires, provides a long service life across a vast range of industrial, construction, and commercial uses.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 5 | 9.2 | 9 | 10.1 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.4 | 16.6 | 16.1 | 17.4 |

| 6 | 13.3 | 13 | 14.6 | 18.7 | 20.1 | 19.8 | 21.4 | 21 | 22.7 | 22.2 | 24 | 23.2 | 25.1 |

| 7 | 18.1 | 17.6 | 19.9 | 25.4 | 27.4 | 27 | 29.1 | 28.6 | 30.9 | 30.2 | 32.6 | 31.7 | 34.2 |

| 8 | 23.6 | 23 | 25.9 | 33.2 | 35.8 | 35.3 | 38 | 37.4 | 40.3 | 39.5 | 42.6 | 41.3 | 44.6 |

| 9 | 29.9 | 29.1 | 32.8 | 42 | 45.3 | 44.6 | 48.2 | 47.3 | 51 | 50 | 53.9 | 52.3 | 56.5 |

| 10 | 36.9 | 36 | 40.5 | 51.8 | 55.9 | 55.1 | 59.5 | 58.4 | 63 | 61.7 | 66.6 | 64.6 | 69.7 |

| 11 | 44.6 | 43.5 | 49.1 | 62.7 | 67.6 | 66.7 | 71.9 | 70.7 | 76.2 | 74.7 | 80.6 | 78.2 | 84.4 |

| 12 | 53.1 | 51.8 | 58.4 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.9 | 93.1 | 100 |

| 13 | 62.3 | 60.8 | 68.5 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 |

| 14 | 72.2 | 70.5 | 79.5 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 126 | 136 |

| 16 | 94.4 | 92.1 | 104 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 165 | 178 |

| 18 | 119 | 117 | 131 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 209 | 226 |

| 20 | 147 | 144 | 162 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 258 | 279 |

| 22 | 178 | 174 | 196 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 313 | 337 |

| 24 | 212 | 207 | 234 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 372 | 402 |

| 26 | 249 | 243 | 274 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 471 |

| 28 | 289 | 282 | 318 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 |

| 30 | 332 | 324 | 365 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 627 |

| 32 | 377 | 369 | 415 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 714 |

| 34 | 426 | 416 | 469 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 747 | 806 |

| 36 | 478 | 466 | 525 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 |

| 38 | 532 | 520 | 585 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 933 | 1007 |

| 40 | 590 | 576 | 649 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1034 | 1116 |

6x19W+FC Steel Wire Rope

This version is engineered for enhanced flexibility and ease of handling. The natural or synthetic fiber core provides excellent elasticity and acts as a reservoir for lubrication, allowing the rope to spool smoothly and resist kinking. It is the ideal, cost-effective choice for general hoisting, stationary winches, garage doors, and other dynamic applications where the rope is not subjected to intense crushing forces on a multi-layer drum.

6x19W+IWR Steel Wire Rope

For maximum strength and resilience in the most demanding environments, the IWR version is the definitive choice. The internal steel core provides a solid, crush-resistant foundation, significantly boosting the rope’s breaking strength and providing superior resistance to heat and deformation. This makes it essential for heavy-duty applications like main crane hoists, boom lines, and critical overhead lifting where safety and reliability cannot be compromised.