Technical Specifications for 6×55SWS Steel Wire Rope

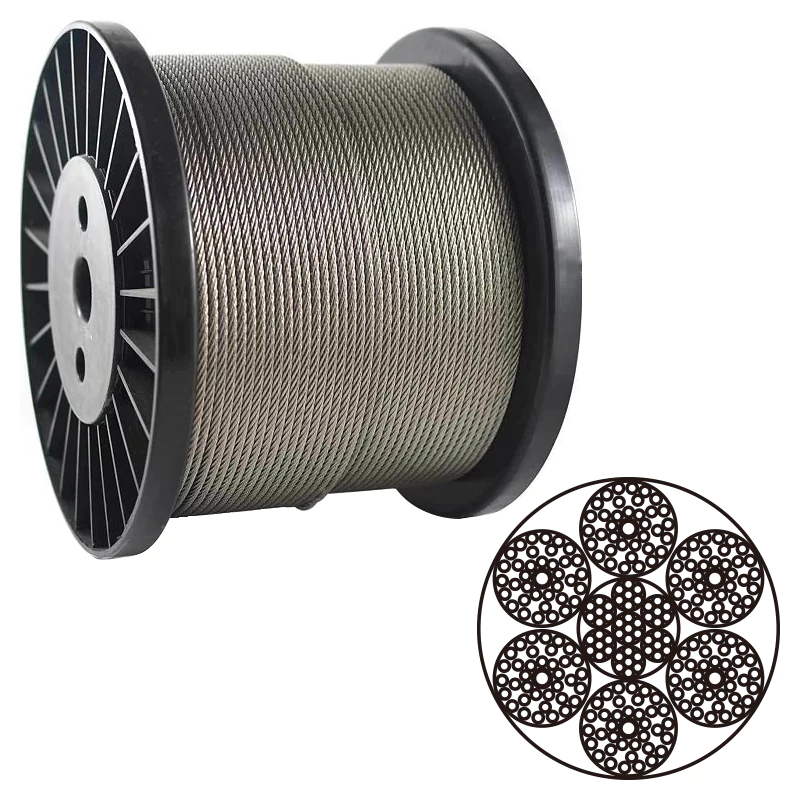

The 6x55SWS classification is less a standard product and more of a bespoke engineering solution for the most extreme dynamic challenges. It stands as the absolute pinnacle of fatigue-resistant design, created for specialized equipment where performance is measured in millions of severe bending cycles under precise conditions.

Its construction features an exceptionally high density of ultra-fine wires, enabling it to operate with unparalleled flexibility in environments where space is minimal and the bending radii are critically small.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 6 | 13.7 | 13.4 | 15 | 18.6 | 20.1 | 19.8 | 21.4 | 21 | 22.6 | 22.2 | 23.9 | 23.2 | 25.1 |

| 8 | 24.3 | 23.7 | 26.8 | 33.2 | 35.8 | 35.3 | 38 | 37.4 | 40.3 | 39.5 | 42.6 | 41.4 | 44.6 |

| 9 | 30.8 | 30.1 | 33.9 | 42 | 45.3 | 44.6 | 48.2 | 47.3 | 51 | 50 | 53.9 | 52.3 | 56.5 |

| 10 | 38 | 37.1 | 41.8 | 51.8 | 55.9 | 55.1 | 59.5 | 58.4 | 63 | 61.7 | 66.6 | 64.6 | 69.7 |

| 11 | 46 | 44.9 | 50.6 | 62.7 | 67.6 | 66.7 | 71.9 | 70.7 | 76.2 | 74.7 | 80.6 | 78.2 | 84.4 |

| 12 | 54.7 | 53.4 | 60.2 | 74.6 | 80.5 | 79.4 | 85.6 | 84.1 | 90.7 | 88.9 | 95.5 | 93.1 | 100 |

| 13 | 64.2 | 62.7 | 70.6 | 87.6 | 94.5 | 93.1 | 100 | 98.7 | 106 | 104 | 113 | 109 | 118 |

| 14 | 74.5 | 72.7 | 81.9 | 102 | 110 | 108 | 117 | 114 | 124 | 121 | 130 | 126 | 136 |

| 16 | 97.3 | 95 | 107 | 133 | 143 | 141 | 152 | 150 | 161 | 158 | 170 | 165 | 178 |

| 18 | 123 | 120 | 135 | 168 | 181 | 179 | 193 | 189 | 204 | 200 | 216 | 209 | 226 |

| 20 | 152 | 148 | 167 | 207 | 224 | 220 | 238 | 234 | 252 | 247 | 266 | 258 | 279 |

| 22 | 184 | 180 | 202 | 251 | 271 | 267 | 288 | 283 | 305 | 299 | 322 | 313 | 337 |

| 24 | 219 | 214 | 241 | 298 | 322 | 317 | 342 | 336 | 363 | 355 | 383 | 372 | 402 |

| 26 | 257 | 251 | 283 | 350 | 378 | 373 | 402 | 395 | 426 | 417 | 450 | 437 | 471 |

| 28 | 298 | 291 | 328 | 406 | 438 | 432 | 466 | 458 | 494 | 484 | 522 | 507 | 547 |

| 30 | 342 | 334 | 376 | 466 | 503 | 496 | 535 | 526 | 567 | 555 | 599 | 582 | 627 |

| 32 | 389 | 380 | 428 | 531 | 572 | 564 | 609 | 598 | 645 | 632 | 682 | 662 | 714 |

| 34 | 439 | 429 | 483 | 599 | 646 | 637 | 687 | 675 | 728 | 713 | 770 | 747 | 806 |

| 36 | 492 | 481 | 542 | 671 | 724 | 714 | 770 | 757 | 817 | 800 | 863 | 838 | 904 |

| 38 | 549 | 536 | 604 | 748 | 807 | 796 | 858 | 843 | 910 | 891 | 961 | 933 | 1007 |

| 40 | 608 | 594 | 669 | 829 | 894 | 882 | 951 | 935 | 1010 | 987 | 1070 | 1034 | 1116 |

| 42 | 670 | 654 | 737 | 914 | 986 | 972 | 1050 | 1030 | 1110 | 1090 | 1170 | 1140 | 1230 |

| 44 | 736 | 718 | 809 | 1000 | 1080 | 1070 | 1150 | 1130 | 1220 | 1190 | 1290 | 1252 | 1350 |

| 46 | 804 | 785 | 884 | 1100 | 1180 | 1170 | 1260 | 1240 | 1330 | 1310 | 1410 | 1368 | 1476 |

| 48 | 876 | 855 | 963 | 1190 | 1290 | 1270 | 1370 | 1350 | 1450 | 1420 | 1530 | 1490 | 1607 |

| 50 | 950 | 928 | 1050 | 1300 | 1400 | 1380 | 1490 | 1460 | 1580 | 1540 | 1660 | 1617 | 1744 |

| 52 | 1030 | 1000 | 1130 | 1400 | 1510 | 1490 | 1610 | 1580 | 1700 | 1670 | 1800 | 1748 | 1886 |

| 54 | 1110 | 1080 | 1220 | 1510 | 1630 | 1610 | 1730 | 1700 | 1840 | 1800 | 1940 | 1886 | 2034 |

| 56 | 1190 | 1160 | 1310 | 1620 | 1750 | 1730 | 1860 | 1830 | 1980 | 1940 | 2090 | 2028 | 2188 |

| 58 | 1280 | 1250 | 1410 | 1740 | 1880 | 1850 | 2000 | 1960 | 2120 | 2080 | 2240 | 2175 | 2347 |

| 60 | 1370 | 1340 | 1500 | 1870 | 2010 | 1980 | 2140 | 2100 | 2270 | 2220 | 2400 | 2328 | 2511 |

6x55SWS+FC Steel Wire Rope

This configuration achieves a level of flexibility that is truly extraordinary, giving it almost textile-like handling properties. Its application is rare and highly specific, typically reserved for counterweight systems, control cables, or other non-load-bearing roles within custom-engineered machinery.

6x55SWS+IWR Steel Wire Rope

This is the primary and essential configuration for nearly all 6x55SWS applications. It integrates the rope’s ultimate flexibility with the vital strength, stability, and crush resistance of a steel core. This makes it an enabling technology for the next generation of compact, high-performance equipment, including certain high-speed elevator compensation ropes, advanced robotics, scientific instrumentation, and other cutting-edge systems where no other wire rope can meet the design specifications.