Technical Specifications

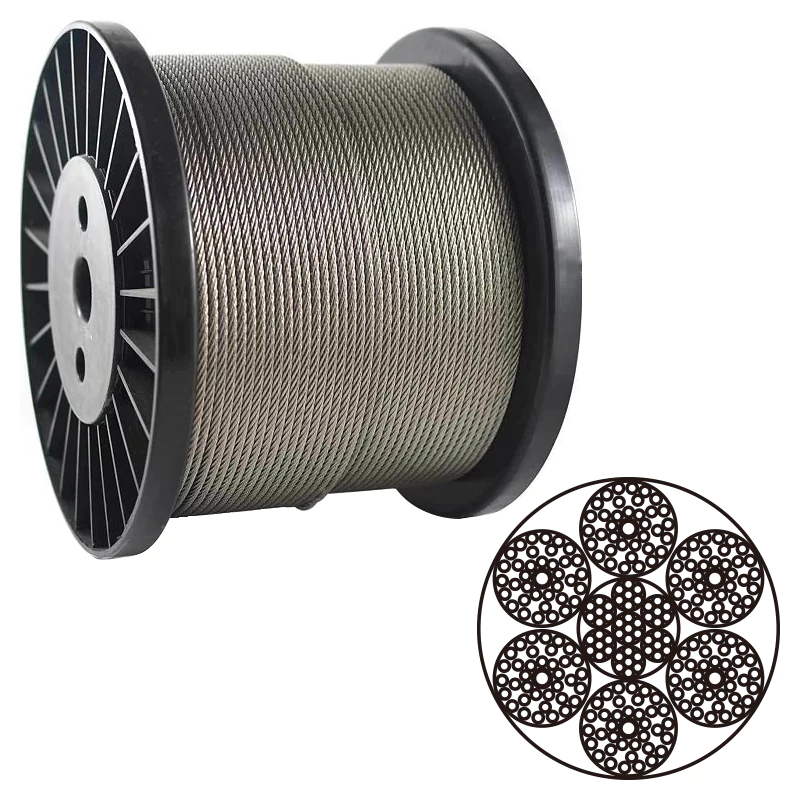

The 6x9w Steel Wire Rope is purpose-built for applications where superior abrasion resistance is the most critical requirement. Unlike more flexible general-purpose ropes, the 6×9 construction utilizes fewer, much thicker wires per strand. This design creates an incredibly rugged outer surface that excels in withstanding extreme surface wear. Due to its inherent rigidity, this rope is not intended for hoisting or frequent bending over sheaves, but it is the ultimate choice for static or low-flexibility roles.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 1.2 | 0.505 | 0.495 | 0.577 | 0.75 | 0.81 | 0.8 | 0.86 | 0.84 | 0.91 | 0.89 | 0.96 | 0.94 | 1 |

| 2 | 1.4 | 1.38 | 1.55 | 2.08 | 2.25 | 2.21 | 2.39 | 2.35 | 2.54 | 2.48 | 2.68 | 2.6 | 2.81 |

| 3 | 3.16 | 3.1 | 3.48 | 4.69 | 5.07 | 4.98 | 5.39 | 5.28 | 5.71 | 5.58 | 6.04 | 5.85 | 6.33 |

| 4 | 5.62 | 5.5 | 6.19 | 8.33 | 9.01 | 8.87 | 9.59 | 9.4 | 10.1 | 9.93 | 10.7 | 10.4 | 11.2 |

| 5 | 8.77 | 8.6 | 9.68 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.5 | 16.7 | 16.2 | 17.6 |

| 6 | 12.6 | 12.4 | 13.9 | 18.7 | 20.2 | 19.9 | 21.5 | 21.1 | 22.8 | 22.3 | 24.1 | 23.4 | 25.3 |

| 7 | 17.2 | 16.9 | 19 | 25.5 | 27.6 | 27.1 | 29.3 | 28.7 | 31.1 | 30.4 | 32.8 | 31.8 | 34.4 |

| 8 | 22.5 | 22 | 24.8 | 33.3 | 36 | 35.4 | 38.3 | 37.6 | 40.6 | 39.7 | 42.9 | 41.6 | 45 |

| 9 | 28.4 | 27.9 | 31.3 | 42.2 | 45.6 | 44.9 | 48.5 | 47.5 | 51.4 | 50.2 | 54.3 | 52.7 | 56.9 |

| 10 | 35.1 | 34.4 | 38.7 | 52.1 | 56.3 | 55.4 | 59.9 | 58.7 | 63.5 | 62 | 67.1 | 65 | 70.3 |

| 11 | 42.5 | 41.6 | 46.8 | 63 | 68.1 | 67 | 72.5 | 71.1 | 76.8 | 75.1 | 81.2 | 78.7 | 85.1 |

| 12 | 50.5 | 49.5 | 55.7 | 75 | 81.1 | 79.8 | 86.3 | 84.6 | 91.5 | 89.4 | 96.6 | 93.7 | 101 |

| 13 | 59.3 | 58.1 | 65.4 | 88 | 95.2 | 93.7 | 101 | 99.3 | 107 | 104 | 113 | 110 | 118 |

| 14 | 68.8 | 67.4 | 75.9 | 102 | 110 | 108 | 117 | 115 | 124 | 121 | 131 | 127 | 138 |

| 16 | 89.9 | 88.1 | 99.1 | 133 | 144 | 141 | 153 | 150 | 162 | 158 | 171 | 166 | 180 |

| 18 | 114 | 111 | 125 | 168 | 182 | 179 | 194 | 190 | 205 | 201 | 217 | 210 | 228 |

| 20 | 140 | 138 | 155 | 208 | 225 | 221 | 239 | 235 | 254 | 248 | 268 | 260 | 281 |

| 22 | 170 | 166 | 187 | 252 | 272 | 268 | 290 | 284 | 307 | 300 | 324 | 315 | 340 |

| 24 | 202 | 198 | 223 | 300 | 324 | 319 | 345 | 338 | 366 | 357 | 386 | 374 | 405 |

| 26 | 237 | 233 | 262 | 352 | 381 | 371 | 405 | 397 | 429 | 419 | 453 | 440 | 475 |

| 28 | 275 | 270 | 303 | 408 | 441 | 434 | 470 | 460 | 498 | 486 | 526 | 510 | 551 |

| 30 | 316 | 310 | 348 | 469 | 507 | 498 | 539 | 528 | 571 | 558 | 604 | 585 | 633 |

| 32 | 359 | 352 | 396 | 533 | 577 | 567 | 613 | 601 | 650 | 635 | 687 | 666 | 720 |

| 34 | 406 | 398 | 447 | 602 | 651 | 640 | 693 | 679 | 734 | 717 | 776 | 752 | 813 |

| 36 | 455 | 446 | 502 | 675 | 730 | 718 | 776 | 761 | 823 | 804 | 870 | 843 | 912 |

| 38 | 507 | 497 | 559 | 752 | 813 | 800 | 865 | 848 | 917 | 896 | 969 | 940 | 1016 |

| 40 | 561 | 550 | 619 | 833 | 901 | 887 | 959 | 940 | 1016 | 993 | 1074 | 1041 | 1125 |

| 42 | 619 | 606 | 682 | 919 | 994 | 978 | 1057 | 1036 | 1120 | 1095 | 1184 | 1147 | 1241 |

| 44 | 679 | 666 | 749 | 1009 | 1091 | 1073 | 1160 | 1137 | 1230 | 1202 | 1300 | 1260 | 1362 |

| 46 | 742 | 728 | 818 | 1102 | 1192 | 1173 | 1268 | 1243 | 1344 | 1313 | 1420 | 1377 | 1488 |

| 48 | 808 | 792 | 891 | 1200 | 1298 | 1277 | 1381 | 1354 | 1464 | 1430 | 1546 | 1499 | 1621 |

6x9W+FC Steel Wire Rope

This is the workhorse for standard static load applications. The fiber core provides a slight cushion and makes this very stiff rope somewhat easier to handle and terminate during the installation of guy wires for towers, antennas, and smokestacks, as well as for standing rigging and structural support cables. It offers a long-lasting, reliable solution for permanent installations with minimal movement.

6x9W+IWR Steel Wire Rope

When maximizing tensile strength is as vital as abrasion resistance, the IWR version is the superior choice. The solid steel core provides maximum structural integrity, a higher breaking load, and greater crush resistance than its fiber core counterpart. It is specified for critical high-tension static lines, bridge supports, and major structural projects where the absolute highest strength and stability are non-negotiable.