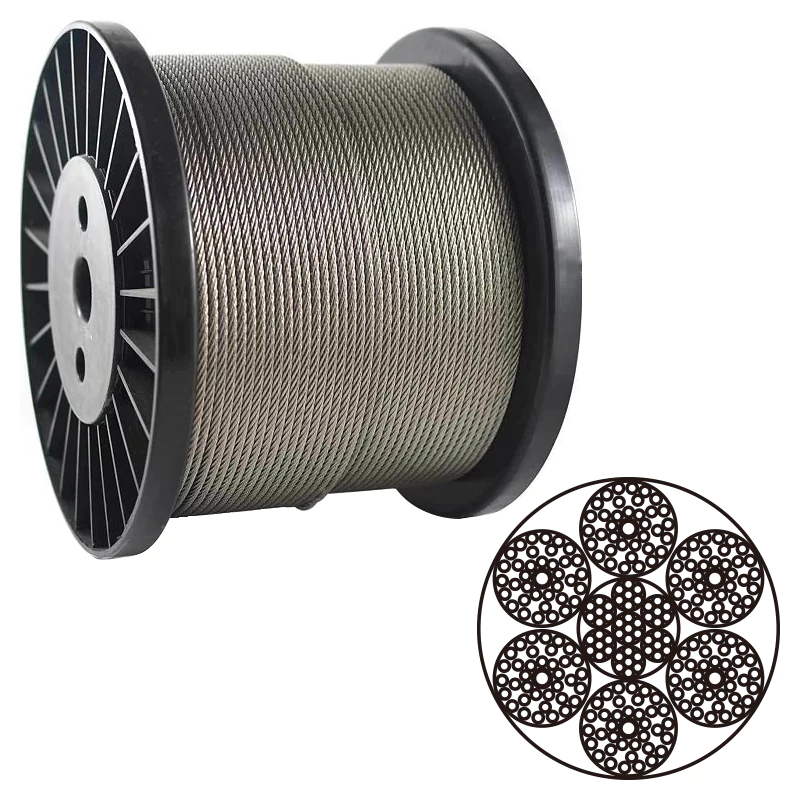

Technical Specifications for 8×25Fi Line Contacted Wire Rope

The 8x25Fi is a top-tier specification designed for elevator systems where longevity, reliability, and resistance to wear are critical. As a “Line Contact” rope, its Filler (Fi) wire construction ensures that all internal wires are laid in parallel, providing full-length support to each other.

This creates a highly compact and stable strand with minimal internal voids, leading to outstanding resistance to crushing forces on the traction sheave and superior fatigue life under constant bending. Combined with the smooth and low-wear benefits of an eight-strand design, the 8x25Fi is the definitive choice for reducing long-term operating costs in high-traffic installations.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 8 | 22.98 | 22 | 27.9 | 29.3 | 34.7 | 31.2 | 36.9 | 33.1 | 39.1 | 35 | 41.3 | 36.7 | 43.4 |

| 9 | 29 | 27.8 | 35.3 | 37.1 | 43.9 | 39.5 | 46.7 | 41.9 | 49.5 | 44.3 | 52.3 | 46.5 | 54.9 |

| 10 | 35.9 | 34.4 | 43.6 | 45.8 | 54.2 | 48.8 | 57.6 | 51.7 | 61.1 | 54.7 | 64.6 | 57.4 | 67.8 |

| 11 | 43.3 | 42.6 | 52.7 | 55.5 | 65.5 | 59 | 69.7 | 62.6 | 73.9 | 66.2 | 78.2 | 69.5 | 82 |

| 12 | 51.5 | 49.5 | 62.8 | 66 | 78 | 70.2 | 83 | 74.5 | 88 | 78.7 | 93 | 82.7 | 97.6 |

| 13 | 60.4 | 58.1 | 73.6 | 77.5 | 91.5 | 82.5 | 97.4 | 87.4 | 103 | 92.4 | 109 | 97 | 114 |

| 14 | 70.1 | 67.4 | 85.4 | 89.8 | 106 | 95.6 | 113 | 101 | 120 | 107 | 127 | 112 | 133 |

| 16 | 91.6 | 88 | 111 | 117 | 139 | 125 | 148 | 132 | 156 | 140 | 165 | 147 | 173 |

| 18 | 116 | 111 | 141 | 149 | 176 | 158 | 187 | 168 | 198 | 177 | 209 | 186 | 220 |

| 20 | 143 | 138 | 174 | 184 | 217 | 195 | 231 | 207 | 224 | 219 | 258 | 230 | 271 |

| 22 | 173 | 166 | 210 | 222 | 262 | 236 | 279 | 250 | 296 | 265 | 313 | 278 | 328 |

| 24 | 206 | 198 | 251 | 264 | 312 | 281 | 332 | 298 | 352 | 315 | 372 | 330 | 390 |

| 26 | 242 | 232 | 295 | 310 | 367 | 330 | 390 | 350 | 413 | 370 | 437 | 388 | 458 |

| 28 | 280 | 270 | 342 | 360 | 425 | 384 | 453 | 406 | 480 | 429 | 507 | 450 | 531 |

| 30 | 322 | 310 | 392 | 414 | 488 | 440 | 520 | 446 | 551 | 493 | 582 | 516 | 610 |

| 32 | 366 | 352 | 446 | 471 | 556 | 501 | 591 | 531 | 627 | 561 | 662 | 588 | 694 |

| 34 | 414 | 398 | 504 | 532 | 628 | 565 | 668 | 600 | 707 | 633 | 747 | 663 | 784 |

| 36 | 464 | 446 | 565 | 596 | 704 | 634 | 748 | 672 | 793 | 710 | 838 | 744 | 878 |

| 38 | 517 | 497 | 630 | 664 | 784 | 706 | 834 | 748 | 884 | 791 | 934 | 829 | 979 |

| 40 | 572 | 550 | 698 | 736 | 869 | 782 | 924 | 830 | 979 | 876 | 1035 | 918 | 1085 |

| 42 | 631 | 607 | 769 | 811 | 958 | 863 | 1019 | 914 | 1080 | 966 | 1141 | 1013 | 1196 |

| 44 | 693 | 666 | 844 | 890 | 1051 | 947 | 1118 | 1004 | 1185 | 1060 | 1252 | 111 | 1312 |

| 46 | 757 | 730 | 922 | 973 | 1140 | 1035 | 1222 | 1090 | 1295 | 1150 | 1360 | 1215 | 1434 |

| 48 | 825 | 793 | 1004 | 1050 | 1251 | 1120 | 1331 | 1194 | 1411 | 1262 | 1490 | 1323 | 1562 |

| 50 | 895 | 860 | 1090 | 1150 | 1358 | 1223 | 1444 | 1296 | 1531 | 1369 | 1617 | 1435 | 1695 |

| 52 | 968 | 930 | 1179 | 1243 | 1468 | 1323 | 1562 | 1402 | 1655 | 1481 | 1749 | 1552 | 1833 |

| 54 | 1044 | 1003 | 1271 | 1341 | 1584 | 1426 | 1684 | 1512 | 1785 | 1597 | 1886 | 1674 | 1977 |

| 56 | 1122 | 1079 | 1367 | 1442 | 1703 | 1534 | 1812 | 1626 | 1920 | 1718 | 2029 | 1800 | 2126 |

| 58 | 1204 | 1157 | 1466 | 1547 | 1827 | 1646 | 1943 | 1744 | 2060 | 1843 | 2176 | 1931 | 2281 |

| 60 | 1288 | 1238 | 1570 | 1656 | 1955 | 1761 | 2080 | 1866 | 2204 | 1972 | 2329 | 2067 | 2441 |

To meet the precise demands of elite projects, we offer two core configurations:

8×25Fi+FC Line Contacted Wire Rope

This is the industry standard for ensuring maximum passenger comfort. The natural fiber core acts as an effective vibration and noise damper, providing the smoothest possible ride. It also serves as a lubricant reservoir, protecting the rope from the inside out. This configuration is the ideal choice for low to mid-rise residential buildings, hotels, and commercial offices where ride quality is paramount.

8×25Fi+IWR Line Contacted Wire Rope

This is the ultimate performance configuration for the most severe applications. The IWR core maximizes the rope’s inherent crush resistance, provides the highest possible breaking strength, and ensures minimal stretch for perfect floor-leveling accuracy. It is the mandatory specification for super high-rise buildings, double-deck elevators, high-speed observation lifts, and ultra-heavy-duty freight elevators where engineering tolerances are tight and performance cannot be compromised.