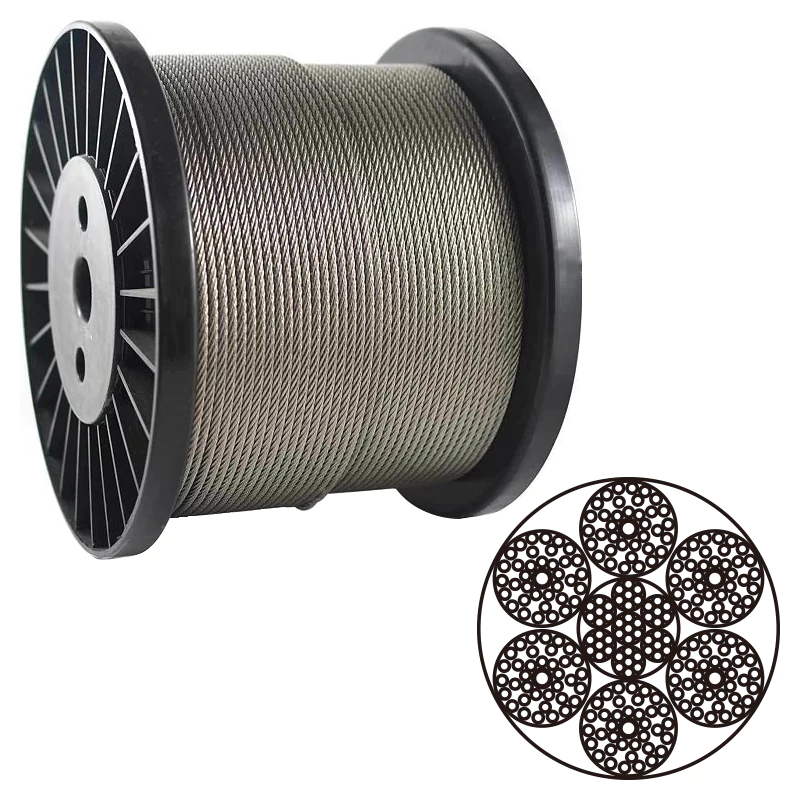

Technical Specifications for 8×55SWS Steel Wire Rope

The 8x55SWS represents the absolute frontier of steel wire rope technology, a bespoke solution crafted for applications that operate beyond the boundaries of conventional mechanical engineering. It is designed not for general industry, but for the world’s leading innovators in science, aerospace, and robotics.

Its construction features the highest achievable density of micro-fine wires, meticulously arranged in a sophisticated eight-strand Warrington Seale pattern. This allows the rope to achieve a level of flexibility and fatigue endurance that explores the absolute physical limits of steel, enabling the development of next-generation, hyper-compact mechanisms.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 8 | 22.98 | 22 | 27.9 | 29.3 | 34.7 | 31.2 | 36.9 | 33.1 | 39.1 | 35 | 41.3 | 36.7 | 43.4 |

| 9 | 29 | 27.8 | 35.3 | 37.1 | 43.9 | 39.5 | 46.7 | 41.9 | 49.5 | 44.3 | 52.3 | 46.5 | 54.9 |

| 10 | 35.9 | 34.4 | 43.6 | 45.8 | 54.2 | 48.8 | 57.6 | 51.7 | 61.1 | 54.7 | 64.6 | 57.4 | 67.8 |

| 11 | 43.3 | 42.6 | 52.7 | 55.5 | 65.5 | 59 | 69.7 | 62.6 | 73.9 | 66.2 | 78.2 | 69.5 | 82 |

| 12 | 51.5 | 49.5 | 62.8 | 66 | 78 | 70.2 | 83 | 74.5 | 88 | 78.7 | 93 | 82.7 | 97.6 |

| 13 | 60.4 | 58.1 | 73.6 | 77.5 | 91.5 | 82.5 | 97.4 | 87.4 | 103 | 92.4 | 109 | 97 | 114 |

| 14 | 70.1 | 67.4 | 85.4 | 89.8 | 106 | 95.6 | 113 | 101 | 120 | 107 | 127 | 112 | 133 |

| 16 | 91.6 | 88 | 111 | 117 | 139 | 125 | 148 | 132 | 156 | 140 | 165 | 147 | 173 |

| 18 | 116 | 111 | 141 | 149 | 176 | 158 | 187 | 168 | 198 | 177 | 209 | 186 | 220 |

| 20 | 143 | 138 | 174 | 184 | 217 | 195 | 231 | 207 | 224 | 219 | 258 | 230 | 271 |

| 22 | 173 | 166 | 210 | 222 | 262 | 236 | 279 | 250 | 296 | 265 | 313 | 278 | 328 |

| 24 | 206 | 198 | 251 | 264 | 312 | 281 | 332 | 298 | 352 | 315 | 372 | 330 | 390 |

| 26 | 242 | 232 | 295 | 310 | 367 | 330 | 390 | 350 | 413 | 370 | 437 | 388 | 458 |

| 28 | 280 | 270 | 342 | 360 | 425 | 384 | 453 | 406 | 480 | 429 | 507 | 450 | 531 |

| 30 | 322 | 310 | 392 | 414 | 488 | 440 | 520 | 446 | 551 | 493 | 582 | 516 | 610 |

| 32 | 366 | 352 | 446 | 471 | 556 | 501 | 591 | 531 | 627 | 561 | 662 | 588 | 694 |

| 34 | 414 | 398 | 504 | 532 | 628 | 565 | 668 | 600 | 707 | 633 | 747 | 663 | 784 |

| 36 | 464 | 446 | 565 | 596 | 704 | 634 | 748 | 672 | 793 | 710 | 838 | 744 | 878 |

| 38 | 517 | 497 | 630 | 664 | 784 | 706 | 834 | 748 | 884 | 791 | 934 | 829 | 979 |

| 40 | 572 | 550 | 698 | 736 | 869 | 782 | 924 | 830 | 979 | 876 | 1035 | 918 | 1085 |

| 42 | 631 | 607 | 769 | 811 | 958 | 863 | 1019 | 914 | 1080 | 966 | 1141 | 1013 | 1196 |

| 44 | 693 | 666 | 844 | 890 | 1051 | 947 | 1118 | 1004 | 1185 | 1060 | 1252 | 111 | 1312 |

| 46 | 757 | 730 | 922 | 973 | 1140 | 1035 | 1222 | 1090 | 1295 | 1150 | 1360 | 1215 | 1434 |

| 48 | 825 | 793 | 1004 | 1050 | 1251 | 1120 | 1331 | 1194 | 1411 | 1262 | 1490 | 1323 | 1562 |

| 50 | 895 | 860 | 1090 | 1150 | 1358 | 1223 | 1444 | 1296 | 1531 | 1369 | 1617 | 1435 | 1695 |

| 52 | 968 | 930 | 1179 | 1243 | 1468 | 1323 | 1562 | 1402 | 1655 | 1481 | 1749 | 1552 | 1833 |

| 54 | 1044 | 1003 | 1271 | 1341 | 1584 | 1426 | 1684 | 1512 | 1785 | 1597 | 1886 | 1674 | 1977 |

| 56 | 1122 | 1079 | 1367 | 1442 | 1703 | 1534 | 1812 | 1626 | 1920 | 1718 | 2029 | 1800 | 2126 |

| 58 | 1204 | 1157 | 1466 | 1547 | 1827 | 1646 | 1943 | 1744 | 2060 | 1843 | 2176 | 1931 | 2281 |

| 60 | 1288 | 1238 | 1570 | 1656 | 1955 | 1761 | 2080 | 1866 | 2204 | 1972 | 2329 | 2067 | 2441 |

8x55SWS+FC Line Contacted Wire Rope

This configuration is an exhibition of manufacturing possibility, producing a steel rope with an almost textile-like pliability. Its application is theoretical and reserved for non-load-bearing roles in proof-of-concept prototypes, advanced sensor arrays, or as a component in highly specific scientific apparatus where extreme flexibility is the sole requirement.

8x55SWS+IWR Line Contacted Wire Rope

This is the only functional configuration for any practical application of the 8x55SWS. It is the enabling technology that harnesses the rope’s unprecedented flexibility for load-bearing tasks. By integrating a solid steel core, it provides the essential strength and structural integrity required for use in future generations of ultra-compact robotics, components within high-energy physics experiments, deep-space exploration mechanisms, and other groundbreaking projects where no other material can meet the extreme specifications.