Technical Specifications for 6×7 Steel Wire Rope

The following table details specifications for our 6×7 steel wire ropes. Please note that breaking loads and weights will differ between FC and IWS core types.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 1.2 | 0.505 | 0.495 | 0.577 | 0.75 | 0.81 | 0.8 | 0.86 | 0.84 | 0.91 | 0.89 | 0.96 | 0.94 | 1 |

| 2 | 1.4 | 1.38 | 1.55 | 2.08 | 2.25 | 2.21 | 2.39 | 2.35 | 2.54 | 2.48 | 2.68 | 2.6 | 2.81 |

| 3 | 3.16 | 3.1 | 3.48 | 4.69 | 5.07 | 4.98 | 5.39 | 5.28 | 5.71 | 5.58 | 6.04 | 5.85 | 6.33 |

| 4 | 5.62 | 5.5 | 6.19 | 8.33 | 9.01 | 8.87 | 9.59 | 9.4 | 10.1 | 9.93 | 10.7 | 10.4 | 11.2 |

| 5 | 8.77 | 8.6 | 9.68 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.5 | 16.7 | 16.2 | 17.6 |

| 6 | 12.6 | 12.4 | 13.9 | 18.7 | 20.2 | 19.9 | 21.5 | 21.1 | 22.8 | 22.3 | 24.1 | 23.4 | 25.3 |

| 7 | 17.2 | 16.9 | 19 | 25.5 | 27.6 | 27.1 | 29.3 | 28.7 | 31.1 | 30.4 | 32.8 | 31.8 | 34.4 |

| 8 | 22.5 | 22 | 24.8 | 33.3 | 36 | 35.4 | 38.3 | 37.6 | 40.6 | 39.7 | 42.9 | 41.6 | 45 |

| 9 | 28.4 | 27.9 | 31.3 | 42.2 | 45.6 | 44.9 | 48.5 | 47.5 | 51.4 | 50.2 | 54.3 | 52.7 | 56.9 |

| 10 | 35.1 | 34.4 | 38.7 | 52.1 | 56.3 | 55.4 | 59.9 | 58.7 | 63.5 | 62 | 67.1 | 65 | 70.3 |

| 11 | 42.5 | 41.6 | 46.8 | 63 | 68.1 | 67 | 72.5 | 71.1 | 76.8 | 75.1 | 81.2 | 78.7 | 85.1 |

| 12 | 50.5 | 49.5 | 55.7 | 75 | 81.1 | 79.8 | 86.3 | 84.6 | 91.5 | 89.4 | 96.6 | 93.7 | 101 |

| 13 | 59.3 | 58.1 | 65.4 | 88 | 95.2 | 93.7 | 101 | 99.3 | 107 | 104 | 113 | 110 | 118 |

| 14 | 68.8 | 67.4 | 75.9 | 102 | 110 | 108 | 117 | 115 | 124 | 121 | 131 | 127 | 138 |

| 16 | 89.9 | 88.1 | 99.1 | 133 | 144 | 141 | 153 | 150 | 162 | 158 | 171 | 166 | 180 |

| 18 | 114 | 111 | 125 | 168 | 182 | 179 | 194 | 190 | 205 | 201 | 217 | 210 | 228 |

| 20 | 140 | 138 | 155 | 208 | 225 | 221 | 239 | 235 | 254 | 248 | 268 | 260 | 281 |

| 22 | 170 | 166 | 187 | 252 | 272 | 268 | 290 | 284 | 307 | 300 | 324 | 315 | 340 |

| 24 | 202 | 198 | 223 | 300 | 324 | 319 | 345 | 338 | 366 | 357 | 386 | 374 | 405 |

| 26 | 237 | 233 | 262 | 352 | 381 | 371 | 405 | 397 | 429 | 419 | 453 | 440 | 475 |

| 28 | 275 | 270 | 303 | 408 | 441 | 434 | 470 | 460 | 498 | 486 | 526 | 510 | 551 |

| 30 | 316 | 310 | 348 | 469 | 507 | 498 | 539 | 528 | 571 | 558 | 604 | 585 | 633 |

| 32 | 359 | 352 | 396 | 533 | 577 | 567 | 613 | 601 | 650 | 635 | 687 | 666 | 720 |

| 34 | 406 | 398 | 447 | 602 | 651 | 640 | 693 | 679 | 734 | 717 | 776 | 752 | 813 |

| 36 | 455 | 446 | 502 | 675 | 730 | 718 | 776 | 761 | 823 | 804 | 870 | 843 | 912 |

| 38 | 507 | 497 | 559 | 752 | 813 | 800 | 865 | 848 | 917 | 896 | 969 | 940 | 1016 |

| 40 | 561 | 550 | 619 | 833 | 901 | 887 | 959 | 940 | 1016 | 993 | 1074 | 1041 | 1125 |

| 42 | 619 | 606 | 682 | 919 | 994 | 978 | 1057 | 1036 | 1120 | 1095 | 1184 | 1147 | 1241 |

| 44 | 679 | 666 | 749 | 1009 | 1091 | 1073 | 1160 | 1137 | 1230 | 1202 | 1300 | 1260 | 1362 |

| 46 | 742 | 728 | 818 | 1102 | 1192 | 1173 | 1268 | 1243 | 1344 | 1313 | 1420 | 1377 | 1488 |

| 48 | 808 | 792 | 891 | 1200 | 1298 | 1277 | 1381 | 1354 | 1464 | 1430 | 1546 | 1499 | 1621 |

Contact us for detailed specifications on our 6×7 fc galvanized steel wire ropes or for any custom requirements.

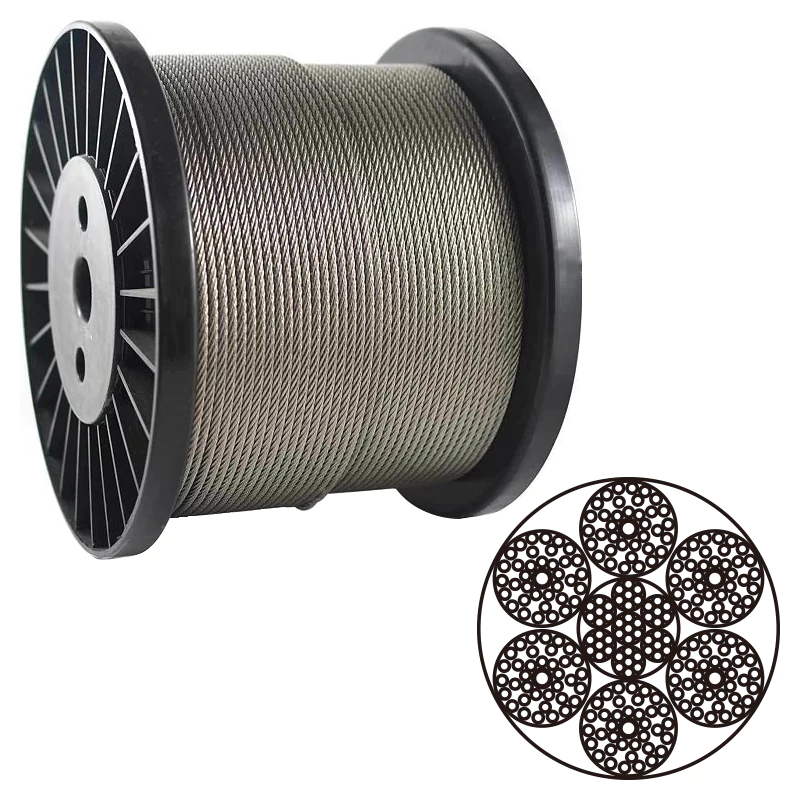

What is a 6×7 FC Steel Wire Rope?

The 6×7 FC steel wire rope classification denotes a specific and robust construction: six outer strands, each composed of seven individual wires, are helically wrapped around a central Fiber Core (FC). The defining characteristic of the 6×7 construction is its use of fewer, thicker wires per strand compared to more flexible ropes. This creates a tough, durable outer surface with exceptional resistance to abrasion, scraping, and friction.

The Fiber Core provides good flexibility for general-purpose applications and acts as a crucial reservoir for lubrication, protecting the wires from internal friction. While the FC core is ideal for many uses, we also offer a 6×7 IWS (Independent Wire Strand) core. The solid steel strand core provides superior support to the outer strands, making it the better choice for applications where the rope is subject to high crushing forces on a drum.

6×7+IWR Steel Wire Rope

This version is designed for applications demanding higher breaking strength and maximum rigidity. The steel core replaces the fiber core, making the rope even stiffer and significantly increasing its tensile strength while minimizing constructional stretch. It is specified for high-tension support systems, critical structural bracing, and scenarios where the rope must act as a solid, non-yielding tie-down.

Features & Benefits of 6×7 Steel Wire Rope

Superior Abrasion Resistance

Constructed with fewer, thicker outer wires, the 6×7 rope offers exceptional resistance to scraping, rubbing, and general surface wear, ensuring a long service life in high-contact applications.

Excellent Corrosion Protection

We offer high-quality 6×7 FC galvanized steel wire ropes for outdoor use. This hot-dipped 6×7+fc galvanised wire rope creates a durable zinc barrier against moisture and rust.

Good Flexibility with Fiber Core

The central Fiber Core (FC) provides the rope with a good degree of flexibility for general-purpose use and helps cushion the strands during operation, reducing the effects of internal wire friction.

Core Options for Specific Demands

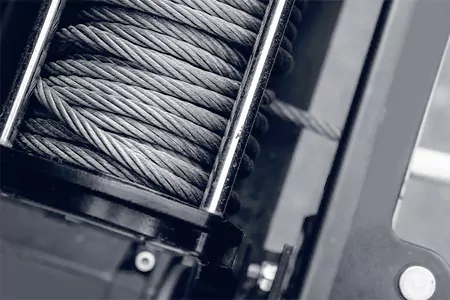

While the standard 6×7 FC wire rope is highly versatile, the 6×7 IWS version with its steel core offers superior crush resistance, making it ideal for multi-layer winding on winch drums.

Common Applications of 6×7 Steel Wire Rope

Winch & Pulling Lines

Ideal as a durable winch line for light-duty applications such as boat trailers, ATV recovery, and other general pulling tasks where the rope may drag on the ground.

Garage Doors & Lifts

Widely trusted as the primary lifting cable in residential and commercial garage door systems, offering a long service life despite the daily cycles and rubbing on pulleys.

Guy Wires & Support Lines

Serves as a strong and reliable guy wire for small towers, antennas, and poles, as well as for general structural bracing and support applications.

Industrial & Agricultural Use

A versatile choice for various industrial tie-downs, lashing, control cables, and in agricultural machinery where a tough, wear-resistant rope is needed.

Quality Assurance & Standards

Quality is the foundation of every product we manufacture. Our 6×7 steel wire rope is produced in facilities that adhere to stringent international standards such as ASTM, ISO, and EN.

From raw material verification to final breaking load tests, our dedicated quality control team monitors every stage of the production process. This rigorous oversight ensures that every rope meets its specified requirements for performance, consistency, and safety.

We provide full material traceability, and Mill Test Certificates (MTCs) are available upon request, giving you complete, documented confidence in the product you receive.

Get a Competitive Quote for Your Project

Tell us your requirements—including diameter, finish (galvanized or bright), core type (FC or IWS), and quantity—and our team will provide a prompt quote for your project.