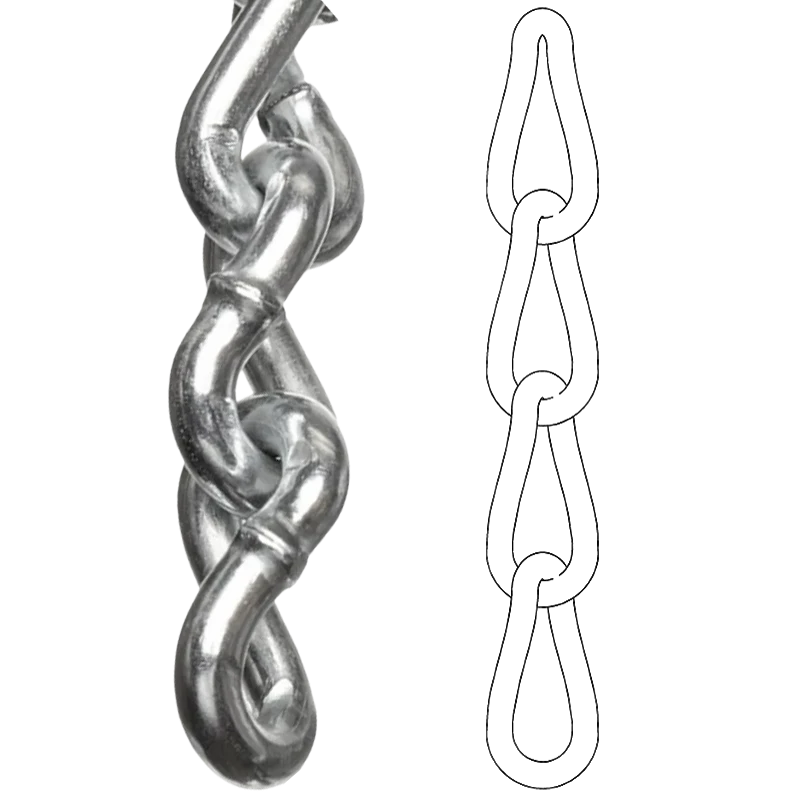

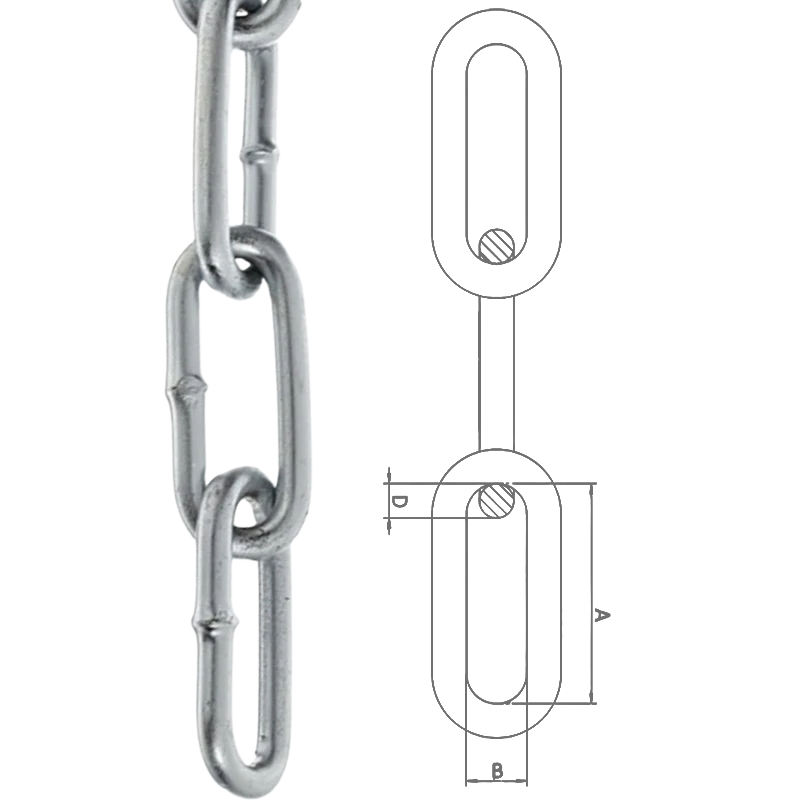

DIAGRAMS

PRODUCT SPECIFICATIONS

| SIZE | A | B | MBL | Weight |

| mm | mm | lbs | kg/pc | |

| 3/4″ x 7′ | 75 | 32 | 55000 | 19.68 |

| 3/4″ x 7′ | 75 | 32 | 75000 | 19.68 |

| 3/4″ x 9′ | 75 | 32 | 75000 | 25.1 |

| 7/8″ x 7′ | 90.5 | 38 | 80000 | 23.21 |

| 1″ x 7′ | 98.5 | 39 | 90000 | 29.29 |

DESIGN

MATERIAL

- Carbon steel/Alloy Steel/Galvanized Alloy

Color

- According to your requirements

FINISH

- Self Coloured/Hot Dip Galvanizing

PACKAGING

- Bulk, Ton bag or as customer request

APPLICATION

- Mooring and Log Booming

INSTRUCTIONS & CAUTIONS

WORKING LOAD LIMITS: This is the maximum load a chain should ever handle, even when it’s new and the load is evenly distributed along a straight, untwisted length. The “working load limit” doesn’t reflect the load the chain could potentially endure if conditions like wear, twisting, misuse, overloading, or corrosion are introduced. These factors can reduce the chain’s strength, so regular inspections are crucial to ensure safety.

PROOF TEST: This is the load a chain undergoes before leaving the factory. The chain is tested under direct tension in a straight line at a consistent speed using a standard testing machine. The purpose of this test is to identify any material or manufacturing defects.

All anchor chains are proof tested. When using attachments like hooks or rings, make sure they match the chain’s grade, type, and size for proper load-bearing performance.

OUR ADVANTAGES

Tailored Customization

We provide custom boom chains to fit your specific needs. Whether it’s size, material, finish, or strength grade, we’ve got you covered. This flexibility makes our chains ideal for everything from industrial to agricultural and marine applications.

Built to Last

Our chains are made from high-quality materials like carbon steel and alloy steel, designed to perform under tough conditions. They resist corrosion, handle heavy use, and keep working long-term, no matter how demanding the environment.

Industry-Approved

All our chains are made to meet elevant certifications, so you can trust their safety and reliability. We ensure that every chain performs to the highest specifications, keeping you compliant with industry regulations.

Great Value with Bulk Discounts

Get the best value for your money with our competitive pricing and bulk discounts for large orders. We make sure you get a great deal without compromising on the quality of our log boom chains.

FAQ

What is a Chain Boom?

A chain boom is a structure made of heavy-duty chains used to create a floating barrier for logs in water. It links logs together to form a floating boom, which helps contain or transport logs safely on rivers or lakes. Chain booms are commonly used in the logging industry, providing a reliable and effective method of managing and moving large quantities of timber in aquatic environments.

What Does a Log Boom Chain Do?

A log boom chain securely connects logs to create a floating barrier, allowing for efficient containment and transport of logs in water. The chain holds the logs together, preventing them from drifting apart and ensuring that they stay in a controlled area for easier handling. It’s essential in log booming systems and is designed to withstand harsh water conditions while maintaining strength and flexibility.

Can Log Boom Chains be used in saltwater?

Yes, log boom chains made from stainless steel or galvanized steel are ideal for use in saltwater environments. These materials are highly resistant to corrosion, ensuring that the chain performs effectively even in harsh marine conditions. Whether used in saltwater rivers or offshore log booming, these chains offer superior longevity and reliability, making them perfect for long-term use in maritime environments.

Are Log Boom Chains customizable in length?

Yes, log boom chains can be customized to the required lengths to fit your specific application. Whether you need shorter chains for small-scale operations or longer chains for larger log booming systems, we provide customization services to meet your needs. Custom lengths ensure a perfect fit for your log containment or transport system, making the process more efficient and safe.

How do I maintain a Log Boom Chain?

-

Regular Inspections: Check the chain for signs of wear, corrosion, or damage to ensure its continued reliability.

-

Clean Periodically: Wash the chain with fresh water to remove salt or debris that can cause wear or corrosion.

-

Apply Rust Inhibitor or Lubricant: Use a rust inhibitor or chain lubricant to protect the chain from corrosion and ensure smooth operation.

-

Proper Storage: Store the chain properly when not in use to prevent unnecessary wear and extend its lifespan.

-

Ensure Safe Operations: Regular maintenance keeps the chain in top condition, ensuring safe and efficient log booming operations.

What certifications do Log Boom Chains have?

Our log boom chains are certified by recognized industry standards, including RINA and BV. These certifications ensure that our chains meet the highest requirements for safety, durability, and performance in the logging industry. By choosing certified chains, you can be confident that you’re using reliable, compliant equipment that has passed rigorous safety and efficiency tests.

Are Log Boom Chains easy to install?

Yes, log boom chains are designed for easy installation. They typically feature “T” ends that can pass through holes drilled in logs, allowing for quick and secure connections. The flexibility of the chain allows for easy handling, even during setup or adjustments, making it suitable for both small and large-scale log booming systems. Proper installation ensures maximum safety and efficiency in log containment.

What are the benefits of using a Log Boom Chain?

The key benefits of using a log boom chain include enhanced safety, durability, and efficiency in log containment and transport. These chains prevent logs from drifting away and ensure that the logs stay organized during transport. With corrosion-resistant materials and the ability to customize lengths, they provide long-lasting, reliable performance in any water-based log booming system.