Product Specifications

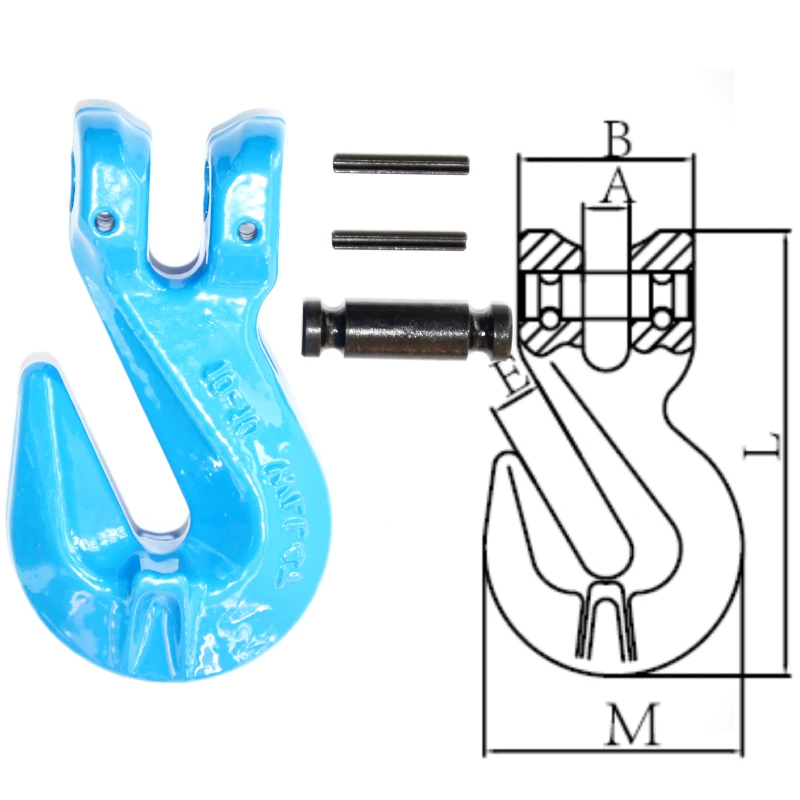

| G80 U.S. TYPE CLEVIS GRAB HOOK | |||||||||

| SIZE | WEIGHT | WLL | B.L | DIMENSIONS(MM) | |||||

| IN. | KG/PC | TON | TON | A | B | E | H | K | L |

| 1/4″ | 0.22 | 1.2 | 4.8 | 8 | 34 | 8 | 19.5 | 57 | 90.5 |

| 9/32″ | 0.31 | 2 | 8 | 9.5 | 41 | 9.5 | 23 | 65.3 | 106.5 |

| 3/8″ | 0.7 | 3.2 | 12.8 | 12.7 | 46 | 12.5 | 31 | 82 | 137 |

| 1/2″ | 1.8 | 5.4 | 21.6 | 16 | 61 | 16.7 | 43 | 113 | 184.5 |

| 5/8″ | 3.1 | 8.2 | 32.8 | 19.5 | 68.5 | 20 | 49 | 129.5 | 215 |

| 3/4″ | 4.1 | 12.8 | 51.2 | 24 | 88 | 24 | 58 | 152 | 254 |

| 7/8″ | 6.2 | 15.5 | 62 | 27 | 96 | 26 | 64.8 | 178 | 295 |

Products Diagrams

Shows the hook’s thick clevis pin and wide throat, highlighting robust load-bearing Grade 80 alloy forged shape, ready for demanding rigging tasks.

Reveals its curved “grab” design and zinc or plastified finish, showing minimal sharp edges and precise hook-to-chain fit.

Material Specification

Grade: Grade 80 alloy steel forged to meet EN 818-2 / ASTM standards for chain hooks; rated for high tensile strength and fatigue load.

Finish: Zinc plated or powder-coated finish resists rust, abrasion, outdoor exposure; optional color coding for safety or brand identity.

Attachment: Clevis fitting with strong pin and locking split-pin; ensures secure connection to chain’s master link or coupling links.

Hook Type: Grab-hook design (“clevis grab”) with throat sized to engage specific chain links, allows shortening or back-hooking of chain.

Material: Alloy steel treated by heat process (quench & temper) to ensure proper hardness and toughness; tested for impact resistance.

Application

Transportation & Freight

Use in transport chain systems for securing loads on flatbed trailers; permits quick chain shortening to avoid slack during transit.

Construction & Rigging

Ideal for scaffolding, lifting brackets, and material hoisting where Grade 80 chain safety and reliable hook engagement are critical.

Agriculture & Logging

Handles heavy log chains or tow systems; resists wear in dusty or wet farm environments with its durable alloy finish.

Advantages

Corrosion Resistance

Each hook is finished with premium zinc or powder coating, providing stronger anti-rust protection than standard market options.

Direct Factory Suppl

We deliver hooks directly from our ISO-certified factory, cutting distributor mark-ups.

Certification

We guarantee UL/CE compliance, ensuring safer, longer-lasting performance for demanding heavy-duty applications.

QC

Every batch undergoes crack detection, proof load testing, and dimensional checks.

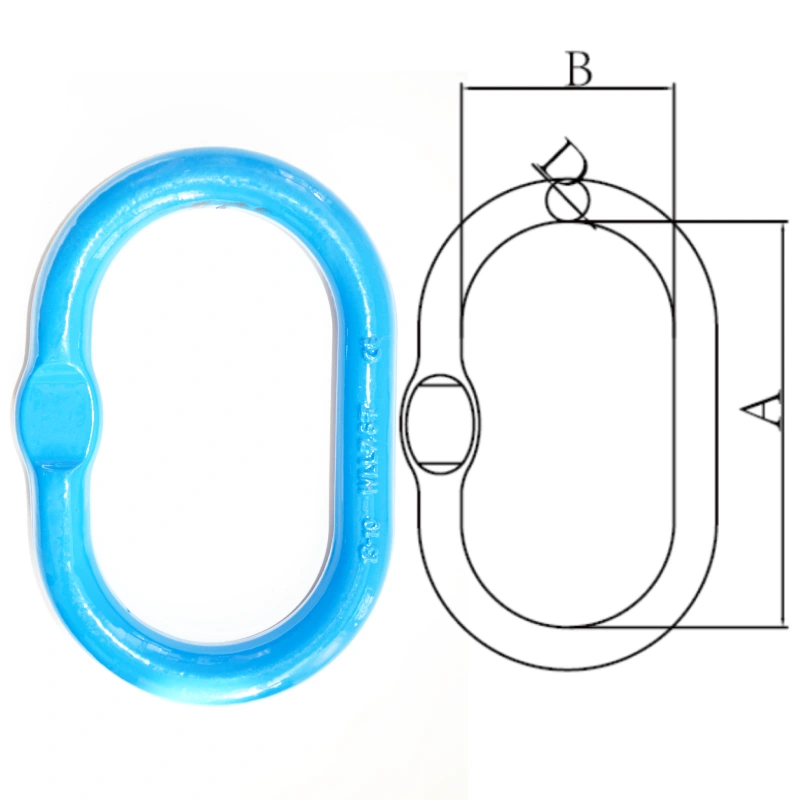

Supporting Products

Grade 80 Chain

matched chain links that carry same load rating, ensuring safety and compatibility.

FAQ

What is the working load limit (WLL) of a Grade 80 clevis grab hook?

The WLL depends on the chain size used with the hook. For example, a 5/16″ G80 hook typically handles about 4,500 lbs (~2,040 kg) when used with matching chain. Always check manufacturer’s rating for your specific size to ensure safety.

Can the hook be used for overhead lifting?

No — clevis grab hooks are generally not permitted for overhead lifting under many safety standards. They are designed for tie-down, load securing, towing or back-hooking chains, not for lifting personnel or loads overhead.

How to ensure compatibility between chain and hook?

Match the chain grade (G80) and chain size (diameter) with hook throat and clevis pin diameter. Using mismatched sizes reduces strength and can lead to dangerous failure.

What safety inspections are needed for grab hooks?

Inspect frequently for cracks, deformation, throat opening enlarged, corrosion, pin wear. If any damage beyond acceptable limits, replace immediately. Safety latch or split pin integrity also critical.

What are the material treatments and how do they improve hook performance?

Hooks are forged from alloy steel, then heat treated (quench-and-temper) to reach high tensile strength and toughness. Surface finish (zinc plate or powder coat) adds corrosion resistance, improving lifespan.

Do you offer custom hook sizes or OEM branding?

Yes. As the manufacturer, we offer custom dimensions, clevis pin sizes, custom finish/colors, and private labeling. These tailored services help distributors and OEMs match specific project requirements.

What quality control measures does your factory take?

We conduct proof-load testing, magnaflux crack detection, and inspect each hook’s clevis pin and split pin. Every batch is traceable with mill certificates and manufacturing records showing Grade 80 alloy compliance.

What is your advantage in price and service compared to competitors?

Because we are direct manufacturer, there’s no middle margin. We offer competitive factory pricing, minimal MOQ for standard sizes, bulk discounts, fast communication, and strong after-sales support for parts or replacements.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.