DIAGRAM

SPECIFICATIONS

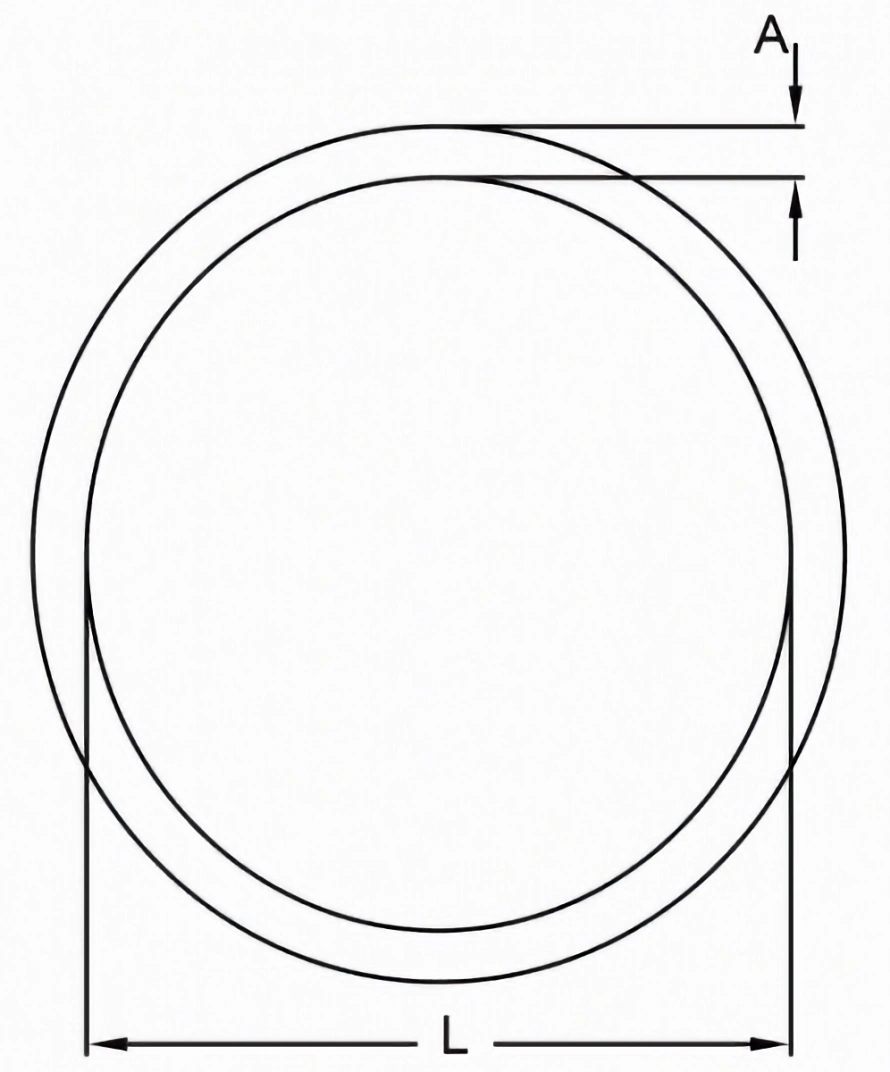

| ITEM NO | A | L | WT | ITEM NO | A | L | WT | |

| mm | mm | KGS | mm | mm | KGS | |||

| HF0436-A/B0315 | 3 | 15 | 0.003 | HF0436-A/B0535 | 5 | 35 | 0.0189 | |

| HF0436-A/B0320 | 3 | 20 | 0.0038 | HF0436-A/B0540 | 5 | 40 | 0.022 | |

| HF0436-A/B0325 | 3 | 25 | 0.0048 | HF0436-A/B0545 | 5 | 45 | 0.0237 | |

| HF0436-A/B0330 | 3 | 30 | 0.005 | HF0436-A/B0550 | 5 | 50 | 0.025 | |

| HF0436-A/B0420 | 4 | 20 | 0.0074 | HF0436-A/B0625 | 6 | 25 | 0.02 | |

| HF0436-A/B0425 | 4 | 25 | 0.0089 | HF0436-A/B0630 | 6 | 30 | 0.0244 | |

| HF0436-A/B0430 | 4 | 30 | 0.0102 | HF0436-A/B0635 | 6 | 35 | 0.0279 | |

| HF0436-A/B0435 | 4 | 35 | 0.012 | HF0436-A/B0640 | 6 | 40 | 0.031 | |

| HF0436-A/B0440 | 4 | 40 | 0.013 | HF0436-A/B0645 | 6 | 45 | 0.035 | |

| HF0436-A/B0525 | 5 | 25 | 0.0146 | HF0436-A/B0650 | 6 | 50 | 0.0384 | |

| HF0436-A/B0530 | 5 | 30 | 0.016 | HF0436-A/B0655 | 6 | 55 | 0.042 | |

| ITEM NO | A | L | WT | ITEM NO | A | L | WT | |

| mm | mm | KGS | mm | mm | KGS | |||

| HF0436-A/B0660 | 6 | 60 | 0.045 | HF0436-A/B1080 | 10 | 80 | 0.180 | |

| HF0436-A/B0840 | 8 | 40 | 0.0587 | HF0436-A/B10100 | 10 | 100 | 0.212 | |

| HF0436-A/B0845 | 8 | 45 | 0.069 | HF0436-A/B1260 | 12 | 60 | 0.193 | |

| HF0436-A/B0850 | 8 | 50 | 0.077 | HF0436-A/B1270 | 12 | 70 | 0.217 | |

| HF0436-A/B0855 | 8 | 55 | 0.0814 | HF0436-A/B1280 | 12 | 14 | 0.260 | |

| HF0436-A/B0860 | 8 | 60 | 0.0814 | HF0436-A/B12100 | 12 | 100 | 0.308 | |

| HF0436-A/B0870 | 8 | 70 | 0.097 | HF0436-A/B1475 | 14 | 75 | 0.331 | |

| HF0436-A/B0880 | 8 | 80 | 0.106 | HF0436-A/B1490 | 14 | 90 | 0.411 | |

| HF0436-A/B1050 | 10 | 50 | 0.108 | HF0436-A/B1975 | 19 | 75 | 0.663 | |

| HF0436-A/B1060 | 10 | 60 | 0.136 | HF0436-A/B1990 | 19 | 90 | 0.772 | |

| HF0436-A/B1070 | 10 | 70 | 0.151 | |||||

PRODUCT FEATURES

- Material: 304 or 316 stainless steel for enhanced corrosion resistance

- Durability: Polished finish for maximum resistance to rust and wear

- Certifications: Proof tested and meets OSHA and ASME standards

- Sizes: Available in diameters from 3mm to 19mm, catering to a variety of needs

- Applications: Ideal for marine, industrial rigging, webbing, decorative, and food service uses

INSTRUCTIONS & CAUTIONS

Check Load Capacity Before Use

Before using a stainless steel round ring, always ensure it’s rated for the load you’ll be lifting or securing. Overloading the ring can cause it to fail, leading to unsafe conditions. If you’re unsure of the appropriate size or load rating, feel free to reach out to our team for guidance. Using the right ring for your application ensures the safety and longevity of your rigging setup.

Inspect for Damage Regularly

Inspect the stainless steel round ring before each use to check for any signs of wear, cracks, or corrosion. Even minor damage can weaken the ring and affect its performance. If any issues are detected, replace the ring immediately to avoid any failures during operation. Regular inspections help maintain the safety and reliability of your rigging system.

Ensure Proper Installation

When installing the stainless steel round ring, make sure it’s securely attached to the rigging components. Whether you’re using ropes, chains, or webbing, the connection should be tight and firm. Loose fittings can cause the ring to slip or fail under load. Follow the manufacturer’s installation instructions and always double-check before use to avoid accidents.

Avoid Exposure to Harsh Chemicals

While stainless steel round rings are corrosion-resistant, prolonged exposure to certain chemicals or extreme environments can still affect their durability. Avoid using the rings in environments where they are constantly exposed to harsh chemicals or excessive saltwater without proper cleaning. Rinse and dry the rings after use in such conditions to extend their lifespan and maintain optimal performance.

OUR ADVANTAGES

Customization for Your Project

Unlike many other manufacturers, Powerful Machinery offers customizable stainless steel round rings to meet the unique needs of your project. Whether you need specific diameters, load capacities, or finishes, we tailor our products to suit your exact specifications, ensuring perfect compatibility with your rigging systems.

Expert Support and Guidance

When you choose Powerful Machinery, you're not just buying a product; you’re gaining access to expert support. Our team helps you select the right size and material, provides advice on installation, and answers any questions you may have. We ensure you’re fully supported through every step of the process, from ordering to using the product in your rigging setup.

Durable, Long-Lasting Quality

Our stainless steel round rings are made from high-grade 304 or 316 stainless steel, providing excellent corrosion resistance and durability. Unlike other manufacturers, we ensure every ring undergoes strict quality checks. This means fewer replacements and longer-lasting performance, saving you time and money on repairs or replacements.

Fast, Reliable Delivery

We know that downtime can be costly. That’s why we prioritize fast delivery for all orders, whether you're placing a small order or bulk purchase. With Powerful Machinery, you can count on timely shipments that keep your projects on track. We work hard to meet your deadlines and ensure you get your materials when you need them.

OUR REVIEWS

FAQ

Can I use stainless steel round rings for rigging with chain or webbing?

Absolutely! Stainless steel round rings are versatile and can be used with chains, ropes, and webbing. The smooth, corrosion-resistant surface ensures easy and secure attachment to your rigging components, while preventing wear or fraying of the rope or chain. This makes them ideal for a wide range of applications, from industrial rigging to marine setups.

What is the difference between 304 and 316 stainless steel round rings?

304 stainless steel offers good corrosion resistance, making it suitable for most industrial applications. However, 316 stainless steel has superior resistance to corrosion, especially in marine environments or areas exposed to chemicals. The addition of molybdenum in 316 stainless steel gives it enhanced resistance to pitting and chloride ion corrosion, making it a better choice for harsh environments.

Are custom sizes available for stainless steel round rings?

Yes, we offer custom sizes for stainless steel round rings to suit your specific project requirements. Whether you need a specific diameter, thickness, or load capacity, we can tailor the rings to meet your exact specifications. Custom orders ensure that your rigging system is perfectly equipped to handle the demands of your application.