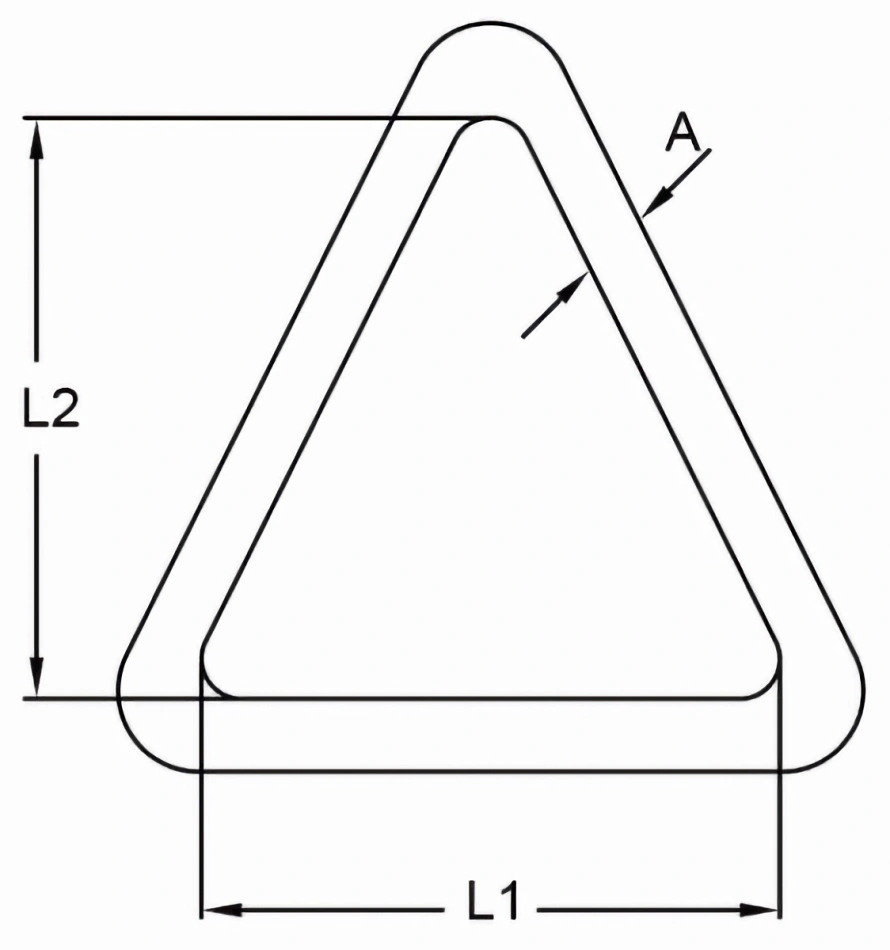

DIAGRAM

SPECIFICATIONS

| ITEM NO | A | L1 | WT | ITEM NO | A | L1 | WT | |

| mm | mm | mm | mm | mm | mm | |||

| HF0439-A/B0320 | 3 | 20 | 0.038 | HF0439-A/B0550 | 5 | 50 | 0.02 | |

| HF0439-A/B0330 | 3 | 30 | 0.05 | HF0439-A/B0640 | 6 | 40 | 0.028 | |

| HF0439-A/B0425 | 4 | 25 | 0.08 | HF0439-A/B0645 | 6 | 45 | 0.033 | |

| HF0439-A/B0525 | 5 | 25 | 0.013 | HF0439-A/B0650 | 6 | 50 | 0.037 | |

| HF0439-A/B0530 | 5 | 30 | 0.016 | HF0439-A/B0845 | 8 | 45 | 0.06 | |

| 5 | 45 | 0.02 | HF0439-A/B0850 | 8 | 50 | 0.068 | ||

TRAWL BLOCK DESIGN

- Material: AISI 316 marine-grade stainless steel for superior corrosion resistance

- Finish: High polished for a smooth, durable surface

- Durability: Built to withstand harsh conditions, ideal for marine and industrial uses

- Sizes: Available in 6mm and 8mm diameters to suit various applications

- Applications: Perfect for webbing, strapping, and other rigging setups

INSTRUCTIONS & CAUTIONS

Check Load Capacity Before Use

Before using the stainless steel triangle ring, double-check its load capacity. While these rings are strong, it’s crucial to match the right size and strength to the weight they’ll be supporting. Overloading the ring can lead to failure, so ensure it’s suitable for your rigging setup.

Avoid Overhead Lifting

Stainless steel triangle rings are not intended for overhead lifting applications. They’re great for securing straps or webbing, but not for bearing heavy loads overhead. Using them for lifting can cause unsafe conditions, so always choose the proper components for lifting.

Regularly Inspect for Damage

Inspect the triangle ring often for any signs of wear or damage. Harsh environments can wear down even the toughest materials, so if you notice any corrosion, cracks, or deformation, it’s time to replace the ring. Staying on top of maintenance prevents costly failures down the line.

Proper Installation Is Key

Make sure the triangle ring is installed securely in your rigging system. Whether it’s for webbing, rope, or chain, a proper installation is essential for safe operation. Loose or improperly attached rings can cause the entire system to fail, so always double-check for a secure fit before use.

OUR ADVANTAGES

Custom-Engineered Solutions with Fast Delivery

Powerful Machinery specializes in custom-engineered solutions tailored to your exact specifications. Whether you need specific sizes, finishes, or load capacities, we can create stainless steel triangle rings that fit your project perfectly. With efficient logistics, we ensure quick delivery times to meet your project deadlines, no matter how complex your requirements are.

Direct-from-Manufacturer

By sourcing stainless steel triangle rings directly from Powerful Machinery, you cut out middlemen and save on costs. We handle the entire manufacturing process, ensuring strict quality control at every step. This means you get reliable, high-quality triangle rings at competitive prices, without compromising on durability or performance.

Fully Certified for Safety and Compliance

Our stainless steel triangle rings meet industry standards for safety and performance, and we offer full certifications for all our products. Whether you’re using them in marine, construction, or rigging applications, you can trust that every ring has been thoroughly tested to ensure it meets the highest safety and durability requirements.

One-Stop Sourcing for Rigging Components

We provide a full range of rigging products, making us your one-stop shop for all your hardware needs. From stainless steel triangle rings to shackles, hooks, and chains, we offer everything you need for secure, reliable rigging setups. Our extensive inventory simplifies sourcing, saving you time and hassle when assembling your rigging system.

OUR REVIEWS

FAQ

What is the difference between AISI 304 and AISI 316 stainless steel triangle rings?

AISI 316 stainless steel offers better corrosion resistance, especially in salty or acidic environments. If you’re working in a marine setting or need extra durability, AISI 316 is the better choice. AISI 304, while still durable, isn’t as resistant to harsh conditions as 316.

What are the benefits of a welded stainless steel triangle ring?

Welded stainless steel triangle rings offer added strength and security, as the weld is nearly invisible and ensures a strong bond. They also provide a smooth, corrosion-resistant surface that’s ideal for marine environments. The welded design increases the overall durability and reliability of the ring.

What is the load capacity of a stainless steel triangle ring?

The load capacity of a stainless steel triangle ring depends on its size and material grade. AISI 316 stainless steel rings typically offer higher strength and can handle significant loads. For detailed load capacity information, check product specifications or consult our team to match the right ring to your project’s needs.