DIAGRAM

SPECIFICATIONS

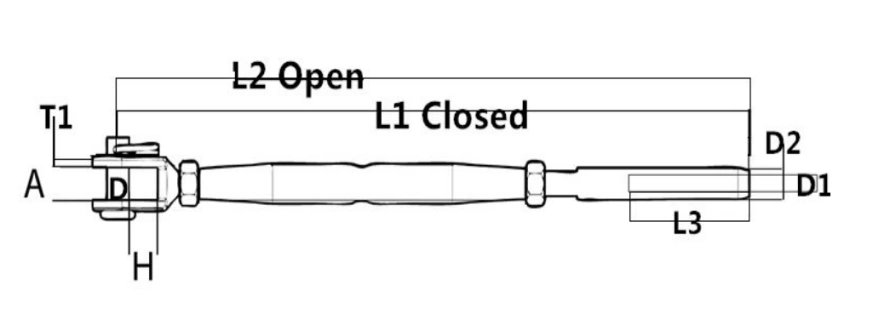

| WIRE | D | L1 | L2 | L3 | A | H | T1 | D1 | D2 |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 2.5 | M5 | 155 | 215 | 32 | 6.5 | 10 | 3 | 2.7 | 5.50 |

| 3 | M6 | 175 | 245 | 39 | 7.5 | 10 | 3 | 3.3 | 6.35 |

| 4 | M6 | 185 | 255 | 45 | 7.5 | 10 | 3 | 4.3 | 7.50 |

| 4 | M8 | 200 | 275 | 45 | 11 | 11 | 3 | 4.3 | 7.50 |

| 5 | M8 | 205 | 280 | 52 | 11 | 11 | 3 | 5.3 | 9.00 |

| 5 | M10 | 230 | 320 | 52 | 12 | 14 | 4 | 5.3 | 9.00 |

| 6 | M10 | 245 | 335 | 64 | 12 | 14 | 4 | 6.4 | 12.60 |

| 6 | M12 | 285 | 400 | 64 | 14 | 20 | 5 | 6.4 | 12.60 |

| 8 | M12 | 305 | 420 | 80 | 14 | 20 | 5 | 8.4 | 16.00 |

| 7 | M14 | 315 | 435 | 70 | 15 | 22 | 5 | 7.4 | 14.20 |

| 8 | M16 | 360 | 500 | 80 | 17 | 26 | 6 | 8.4 | 16.00 |

| 10 | M16 | 370 | 510 | 90 | 17 | 26 | 6 | 10.5 | 18.00 |

| 10 | M20 | 410 | 560 | 90 | 20 | 30 | 6 | 10.5 | 18.00 |

| 12 | M20 | 430 | 580 | 105 | 23 | 35 | 6 | 12.6 | 20.00 |

PRODUCT FEATURES

- Material: AISI 316 Marine Grade Stainless Steel

- Finish: Polished for a clean look

- Corrosion Resistance: High resistance for marine and outdoor environments

- Clevis Pin: Removable and captive with a split ring

- Wire Rope Sizes: Compatible with 2.5mm to 12mm diameter steel wire ropes

- Applications: Ideal for rigging, shade structures, wire balustrades, and marine setups

INSTRUCTIONS & CAUTIONS

Proper Installation

When installing the jaw swage turnbuckle, ensure that it’s securely connected to both ends of the wire rope. Use the correct tools to tighten the turnbuckle and avoid over-tightening, which could cause damage to the threads or reduce the turnbuckle’s lifespan. Always check that the turnbuckle is aligned properly to prevent unnecessary strain on the components.

Regular Inspection

Regularly inspect your jaw swage turnbuckle for signs of wear, corrosion, or damage, especially in marine or outdoor applications. Look for any loose pins, cracks, or rust buildup. If you find any issues, replace the turnbuckle immediately to prevent failure in critical applications. Proper maintenance ensures optimal performance and safety.

Avoid Overloading

Never exceed the rated load capacity of the jaw swage turnbuckle. Overloading can weaken the materials and lead to premature failure. Always follow the manufacturer’s guidelines regarding load limits, and if you’re unsure, consult with an expert to ensure you’re using the correct size and type for your application.

Secure Clevis Pin

The clevis pin should always be properly secured with a captive split ring to prevent accidental dislodging. If the pin is not secured, it could lead to the turnbuckle detaching during use, posing a serious safety risk. Before each use, verify that the pin is correctly in place and locked.

OUR ADVANTAGES

Customizable to Your Needs

We understand every customer has unique needs, which is why we offer custom-engineered solutions tailored to your exact specifications. Whether it’s size, material, or design adjustments, we provide solutions that fit your requirements. Our OEM services let you brand our products as your own, giving your business a competitive edge and helping you stand out in the market.

Direct from Manufacturer

At Powerful Machinery, we offer direct access to high-quality rigging and lifting hardware, cutting out the middleman. This approach means better pricing and faster delivery times for wholesalers and large supermarkets. You get the best value without compromising on quality or service. We make sure the products are readily available when you need them.

Quality & Safety Assurance

We prioritize your safety with every product we make. Powerful Machinery’s turnbuckles and rigging hardware are thoroughly tested to meet international safety standards. Our products are built to last and perform under pressure, giving wholesalers and large supermarkets peace of mind that they’re offering safe, reliable products to their customers.

One-Stop Sourcing

With Powerful Machinery, you get all your rigging hardware needs in one place. From jaw swage turnbuckles to various lifting products, we simplify your procurement process. Our efficient service allows wholesalers and large supermarkets to save time, reduce errors, and streamline their sourcing. You can rely on us for everything you need, under one roof.

OUR REVIEWS

FAQ

How do I tighten a cable with a turnbuckle?

-

Insert the Cable:

Start by inserting the cable into the jaw or swage end of the turnbuckle. -

Secure with Pins:

Once the cable is in place, secure it using the necessary pins to hold the cable in position. -

Use a Wrench to Tighten:

Rotate the turnbuckle with a wrench in a clockwise direction to pull the cable taut. -

Avoid Over-tightening:

Be careful not to over-tighten the turnbuckle, as this can lead to unnecessary strain on both the cable and the hardware. -

Check for Proper Tension:

After tightening, always inspect the cable for proper tension to ensure it’s secure but not over-stretched.

How do I know if my jaw swage turnbuckle is the right size?

To determine the correct size for your jaw swage turnbuckle, match the turnbuckle’s dimensions with the cable or wire rope’s diameter. The turnbuckle should fit snugly with no excess movement when attached to the cable. Be sure to check the manufacturer’s guidelines to ensure the turnbuckle’s load capacity aligns with the strength of your cable and the requirements of your project.

How do I tighten a turnbuckle?

If your trawl block shows signs of significant wear, such as cracks or a damaged sheave, it’s important to replace it immediately to prevent further issues. Don’t use a damaged block, as it can cause equipment failure or accidents. Contact us for replacement parts or a new block, and always make sure to use blocks that meet the working load limit (WLL) of your operation.

How can I prevent my jaw swage turnbuckle from loosening?

-

Tighten Correctly During Installation:

Ensure the turnbuckle is tightened properly when installing to prevent initial loosening. -

Check the Locking Mechanism or Pin:

Always inspect the locking mechanism or pin to ensure it is secure. -

Look for Captive Pins or Locking Features:

Some turnbuckles include captive pins or locking mechanisms for added security. -

Regular Inspections:

Inspect your turnbuckle regularly, especially in environments with vibration or heavy use that may cause it to loosen.

Can I replace the pins on my jaw swage turnbuckle?

Yes, the pins on jaw swage turnbuckles can be replaced if they become damaged or worn out. It’s important to replace them with the correct size and type recommended by the manufacturer to maintain the integrity of the rigging system. Regular inspections can help you identify when the pins need replacement, ensuring the safety and performance of your rigging setup.

Can jaw swage turnbuckles be customized?

Yes, jaw swage turnbuckles can often be customized to meet specific project needs. Customizations can include adjusting the size, material, or finish to suit the requirements of your application. Whether you need a particular jaw size, different thread types, or unique features, manufacturers can provide tailored solutions to meet your specifications.