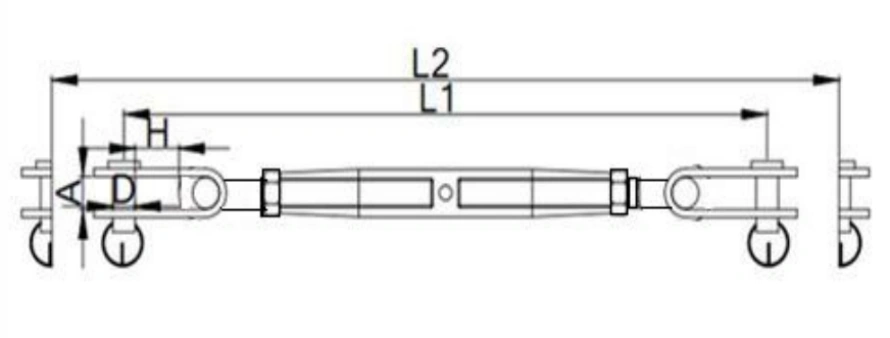

DIAGRAM

SPECIFICATIONS

| SIZE | D | L1 | L2 | A | H | WT |

| mm | mm | mm | mm | mm | KGS | |

| M6 | 6 | 160 | 230 | 7 | 15 | 0.100 |

| M8 | 8 | 190 | 265 | 10 | 20 | 0.191 |

| M10 | 9 | 230 | 320 | 12 | 25 | 0.399 |

| M12 | 12 | 280 | 390 | 13 | 30 | 0.630 |

| M16 | 16 | 370 | 510 | 17 | 40 | 1.450 |

| M20 | 19 | 430 | 570 | 20 | 45 |

TRAWL BLOCK DESIGN

- UNC Threads: Compatible with other turnbuckle fittings.

- Marine Standard: Ideal for tough, high-chloride environments.

- Corrosion Resistant: Durable and long-lasting.

- Type 316 Stainless Steel: Ensures high performance and resistance in harsh conditions.

INSTRUCTIONS & CAUTIONS

Installation of Toggle Turnbuckles

To install toggle turnbuckles, begin by inserting the wire rope into the jaw or swage end of the turnbuckle. Secure it with the appropriate fasteners and connect the other side to the rigging system. Once everything is in place, use a wrench to tighten the turnbuckle until the cable is taut. Make sure the turnbuckle is aligned correctly to avoid uneven tension, and regularly inspect it for proper tightening.

Adjusting Tension

When adjusting the tension of a toggle turnbuckle, rotate the central body clockwise to tighten or counterclockwise to loosen. Always use a wrench to make the adjustment easier. Be sure to check both ends of the turnbuckle for equal tension, as uneven tension can cause damage to the turnbuckle or cable. Don’t over-tighten, as it could lead to unnecessary stress on the system.

Prevent Loosening

To prevent your toggle turnbuckle from loosening, always ensure that it is properly tightened during installation. Use the locking mechanism or clevis pins securely to ensure stability. Regularly inspect the turnbuckle for any signs of loosening or wear, especially in high-vibration environments. If needed, apply a thread-locking compound to keep the turnbuckle in place.

Avoid Overloading

Avoid using toggle turnbuckles beyond their rated load capacity. While they offer great strength and flexibility, overloading the turnbuckle can compromise its performance and cause failure. Always check the load specifications before installation and ensure the turnbuckle is suitable for the application. Use only the recommended wire rope diameter and ensure that the turnbuckle is properly sized for your rigging needs.

OUR ADVANTAGES

Custom Engineered Solutions

Need something specific? Our team works closely with you to create custom toggle turnbuckles or rigging solutions tailored to your project. Whether it's special sizing, unique materials, or custom threading, we provide engineered solutions that meet your exact requirements. This flexibility ensures you can tackle any challenge with confidence and precision, making us the perfect partner for large-scale projects.

Direct from Manufacturer

By purchasing directly from us, you eliminate the middleman, which means more cost savings for you. We offer better prices and faster lead times, ensuring you get the best value for your investment. Plus, you get direct access to our expert team for any questions or support, streamlining your order process and guaranteeing that you're getting exactly what you need.

Fully Certified, Safe Products

We prioritize safety and compliance. Our toggle turnbuckles and rigging hardware are fully certified to meet industry standards, ensuring you’re getting reliable and safe products every time. This means fewer risks and more peace of mind, knowing you're using high-quality equipment that stands up to the toughest conditions, whether it's for marine, construction, or architectural use.

Efficient Logistics & Fast Delivery

We know time is money. That's why we offer efficient logistics and quick shipping to get your bulk orders to you on time. With streamlined processes, we make sure your toggle turnbuckles and other products are delivered without delays. Whether you're in need of standard or customized parts, you can count on us to meet your deadlines and keep your projects on track.

OUR REVIEWS

FAQ

How do toggle turnbuckles work?

Toggle turnbuckles work by adjusting the central body to either tighten or loosen the tension on the connected cables. The swage or jaw end attaches to wire ropes, while the toggle end allows for smooth pivoting and flexible adjustments. By rotating the turnbuckle, you can ensure even tension across the cable system, which is vital for structural stability and load-bearing efficiency.

What materials are toggle turnbuckles made from?

Toggle turnbuckles are typically made from high-quality materials like Type 316 stainless steel, which provides excellent corrosion resistance, making them suitable for marine and high-chloride environments. AISI 304 stainless steel is also used for general applications. These materials ensure durability, strength, and long-lasting performance in various weather conditions and demanding projects.

How do I adjust the tension on a toggle turnbuckle?

-

Use a Wrench:

Rotate the central body of the toggle turnbuckle using a wrench. -

Clockwise to Tighten:

Turn it clockwise to tighten the tension. -

Counterclockwise to Loosen:

Turn it counterclockwise to loosen the tension. -

Ensure Even Adjustment:

Make sure both ends are adjusted evenly to maintain balanced tension across the system. -

Check Regularly:

Always check the tension regularly to prevent over-tightening, which can damage the turnbuckle or cable.

Are toggle turnbuckles compatible with other rigging components?

Yes, toggle turnbuckles feature UNC threads, making them compatible with a variety of other rigging components like clevises, hooks, and other turnbuckle bodies. This ensures easy integration into your existing rigging systems without the need for additional modifications or fittings.

How do I adjust the tension on a toggle turnbuckle?

-

Use a Wrench:

Rotate the central body of the toggle turnbuckle using a wrench. -

Clockwise to Tighten:

Turn it clockwise to tighten the tension. -

Counterclockwise to Loosen:

Turn it counterclockwise to loosen the tension. -

Ensure Even Adjustment:

Make sure both ends are adjusted evenly to maintain balanced tension across the system. -

Check Regularly:

Always check the tension regularly to prevent over-tightening, which can damage the turnbuckle or cable.

Can I order toggle turnbuckles in bulk?

Yes, we offer bulk orders of toggle turnbuckles at competitive pricing for wholesale buyers. We can also customize the order according to your specific needs, whether it’s for large-scale industrial projects or long-term stock requirements. Contact us with your order details, and we’ll provide you with a tailored solution.

How long does delivery take for bulk orders of toggle turnbuckles?

Delivery times vary depending on the order size and location, but we work efficiently to ensure timely shipping. For bulk orders, we aim to dispatch the products within 7–10 business days, and we can provide a more accurate timeline once we receive your order details. We also offer expedited shipping options for urgent requirements.