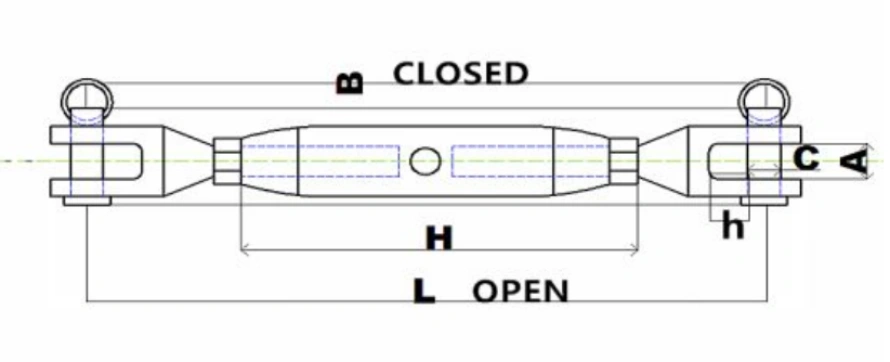

JAW JAW TURNBUCKLE DIAGRAM

SPECIFICATIONS OF JAW AND JAW TURNBUCKLES

| D1 | L | B | H | C | A | 14 | WT |

| mm | mm | mm | mm | mm | mm | mm | KGS |

| 5M | 190 | 130 | 80 | 5 | 6.5 | 10 | 0.055 |

| 6M | 225 | 155 | 95 | 6 | 7.5 | 10 | 0.095 |

| 8M | 255 | 180 | 105 | 8 | 11 | 11 | 0.209 |

| 10M | 300 | 210 | 125 | 9 | 12 | 14 | 0.365 |

| 12M | 380 | 270 | 150 | 12 | 14 | 20 | 0.648 |

| 14M | 415 | 295 | 170 | 12 | 15 | 22 | 0.883 |

| 16M | 480 | 340 | 190 | 16 | 17 | 26 | 1.415 |

PRODUCT FEATURES

- Marine Standard: Suitable for harsh marine environments.

- Corrosion Resistant: Made from high-quality Type 316 stainless steel.

- Closed Body Design: Provides extra strength and reliability.

- Polished Surface: Ensures a smooth, high-quality finish.

INSTRUCTIONS & CAUTIONS

Correct Installation Is Key

When installing the JIS closed body jaw and jaw turnbuckle, make sure both ends are securely attached to the wire rope and anchor points. Use the appropriate pins or connectors to prevent any movement. Always check for proper alignment before tightening. Incorrect installation can lead to uneven tension and may cause damage to both the turnbuckle and wire rope.

Use Proper Tools for Adjustment

To adjust the tension, use a wrench to rotate the turnbuckle’s body. Be sure to tighten or loosen it gradually, checking that the tension is even on both sides. Over-tightening or adjusting too quickly can damage the turnbuckle and cause strain on the wire rope. Always follow the recommended tightening guidelines to ensure safe, long-lasting performance.

Regular Inspections Are Essential

It’s important to inspect the jaw and jaw turnbuckle regularly, especially in high-stress environments like marine or construction. Check for any signs of corrosion, wear, or misalignment. Since the turnbuckle is exposed to various conditions, especially saltwater, regular maintenance ensures its longevity and prevents failure. If any issues are detected, replace the turnbuckle immediately.

Avoid Using for Load-Bearing

The JIS closed body jaw and jaw turnbuckle is designed for tensioning, not load-bearing. It should not be used to lift heavy loads or as a primary weight-bearing device. Misusing the turnbuckle for load-bearing tasks could result in failure or damage to your rigging system. Always use the right equipment for load-bearing applications to ensure safety and compliance with industry standards.

OUR ADVANTAGES

Tailored Solutions and After-Sales Support

At Powerful Machinery, we specialize in custom-engineered solutions to meet the unique requirements of your project. Whether you need specialized turnbuckles or customized fittings, we work with you to create exactly what you need. Plus, our after-sales support ensures you can count on us for maintenance, troubleshooting, and any issues that may arise, long after your order arrives.

Direct from Manufacturer

By sourcing directly from Powerful Machinery, you cut out the middleman, saving on extra costs. This ensures competitive pricing and quicker response times for large orders. As a result, we can provide you with faster deliveries and more customization options. We work closely with you to meet specific needs, making it easier for wholesalers to keep stock levels in check.

One-Stop Sourcing

As a wholesaler, you need a reliable supplier for a variety of rigging and lifting hardware. We provide a one-stop sourcing solution, offering a broad range of toggle turnbuckles, jaw turnbuckles, swage fittings, and more. This simplifies your procurement process, saving you time and hassle in searching for multiple suppliers, all while ensuring product compatibility and consistency.

Quality & Safety You Can Trust

Powerful Machinery places a strong emphasis on quality control and safety. Our products are thoroughly tested to meet international standards, ensuring they’re durable and reliable. Whether it’s marine rigging or heavy-duty tensioning, our rigging hardware delivers long-lasting performance with top-notch safety features that you can count on, especially for your most demanding projects.

OUR REVIEWS

FAQ

How do I install a Jaw and Jaw Turnbuckle?

-

Insert the Wire Rope: Begin by inserting the wire rope into one of the jaws of the turnbuckle. Secure it with a pin or clevis.

-

Attach the Other End: Repeat the same process on the opposite side of the turnbuckle, ensuring both ends are properly secured.

-

Tighten the Turnbuckle: Use a wrench to rotate the turnbuckle. Tighten it slowly while adjusting the tension.

-

Check the Tension: Double-check both sides of the turnbuckle to make sure the tension is even. Ensure the tension is balanced to avoid over-tightening, which could lead to damage.

What is the difference between Jaw and Jaw and other types of turnbuckles?

A Jaw and Jaw Turnbuckle has a forked jaw on both ends, designed to attach securely to eye bolts or other rigging components. It’s more flexible than standard turnbuckles, offering easier installation and better adjustability. Unlike other types, this design is perfect for applications requiring quick adjustments without compromising strength or reliability.

How do I adjust the tension on a Jaw and Jaw Turnbuckle?

To adjust the tension, rotate the central body of the turnbuckle using a wrench. Turn it clockwise to tighten and counterclockwise to loosen the tension. Ensure both sides are adjusted equally to maintain balance. Regularly check the tension to ensure it is secure but not over-tightened, as excessive tension can lead to damage.

What sizes are available for Jaw and Jaw Turnbuckles?

We offer Jaw and Jaw Turnbuckles in various sizes to meet your specific needs. Common sizes range from smaller wire rope connections (e.g., 2.5mm, 3mm) to larger industrial uses (e.g., 12mm). If you need a custom size for a specific application, we can work with you to engineer a turnbuckle that meets your exact specifications.

What’s the difference between Jaw and Jaw Turnbuckles and Swage Turnbuckles?

Jaw and Jaw Turnbuckles feature two jaw ends that allow easy attachment to wire ropes and rigging systems. Swage Turnbuckles, on the other hand, have one end that swages directly onto wire ropes for a more permanent connection. Jaw and Jaw Turnbuckles are more adjustable, making them ideal for tensioning and quick adjustments, while Swage Turnbuckles are often used for fixed installations.

How do I know the right size for my Jaw and Jaw Turnbuckle?

To choose the right size, consider the diameter of the wire rope you’re using and the required load capacity. Generally, you’ll need a turnbuckle that matches the rope’s thickness and has a tension rating suitable for your application. If you’re unsure, feel free to contact our team, and we can help guide you in selecting the best size for your specific needs.

Can I get a sample before placing a bulk order?

Yes, we offer sample services for Jaw and Jaw Turnbuckles so you can check the quality before committing to a bulk order. You can evaluate the fit, finish, and performance of the turnbuckle to ensure it meets your requirements. Contact our sales team to arrange a sample and ensure you’re satisfied with the product before placing your full order.