DIAGRAM

SPECIFICATIONS

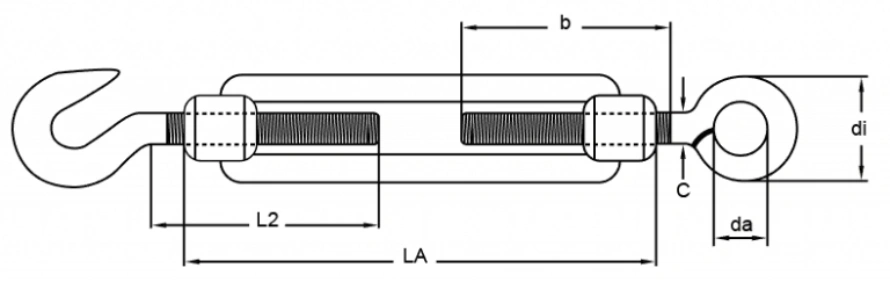

| SIZE | LA | L2 | b | da | C | di | WT |

| mm | mm | mm | mm | mm | mm | mm | KGS |

| 5M | 90 | 55 | 46 | 9.5 | 4.5 | 18.5 | 0.044 |

| 6M | 110 | 60 | 53 | 10 | 4.5 | 19 | 0.078 |

| 8M | 110 | 60 | 55 | 12 | 6.5 | 25 | 0.148 |

| 10M | 125 | 65 | 60 | 14 | 8 | 30 | 0.243 |

| 12M | 125 | 75 | 70 | 18 | 10.5 | 39 | 0.391 |

| 16M | 170 | 100 | 90 | 22 | 13 | 48 | 0.909 |

| 20M | 200 | 115 | 100 | 25 | 20 | 65 | 1.592 |

PRODUCT FEATURES

- Material: AISI304 or AISI316 stainless steel

- Standard: DIN 1480

- Size Range: M5 to M20

- Configurations: Hook-eye, hook-hook

- Compatibility: Works with DIN 34828 weld-on ends

- Applications: Rigging, suspension, and tensioning

INSTRUCTIONS & CAUTIONS

Proper Installation

Before using the JIS DIN 1480 Turnbuckle, make sure both ends are securely attached to the rigging components. Whether you’re using hook-eye or hook-hook configurations, ensure the threads are properly aligned and tightened to prevent slippage or damage. Always double-check that both fittings are firmly in place to maintain safety.

Check for Material Compatibility

When assembling the DIN 1480 Turnbuckle with weld-on ends, ensure they’re made from the same material, like A4-50 stainless steel. This ensures that the turnbuckle’s load capacity remains high. If you’re using materials with different tensile strengths, such as galvanized steel or others, make sure to verify the load-bearing capacity separately to avoid overloading.

Do Not Over-Tighten

While adjusting the turnbuckle, be cautious not to over-tighten it. Excessive tension can weaken the threads or put too much strain on the rigging system, which could lead to component failure. Use the right tools and tighten gradually to avoid any damage to the turnbuckle or connected components.

Regular Inspection and Maintenance

Even though the DIN 1480 Turnbuckle is made from high-quality stainless steel, regular inspections are crucial. Check for signs of corrosion, wear, or damage, especially if exposed to harsh weather conditions. Regularly clean the turnbuckle and lubricate the threads to ensure smooth operation and to extend its lifespan.

OUR ADVANTAGES

Custom-Engineered Solutions

We understand that every rigging application is unique. That’s why we offer custom-engineered solutions tailored to your needs. Whether you need specific sizes, materials, or configurations, we work with you to create the DIN 1480 turnbuckles that perfectly fit your project. This flexibility ensures your systems are optimized for performance and safety.

Direct from Manufacturer

When you order from Powerful Machinery, you’re getting products directly from the source. This eliminates middlemen and helps us offer you more competitive pricing. We control every step of the production process, ensuring our DIN 1480 turnbuckles meet the highest standards for quality and performance. You get a reliable product with faster delivery times.

Efficient Logistics & On-Time Delivery

At Powerful Machinery, we pride ourselves on providing efficient logistics that keep your projects on schedule. We work with trusted transportation partners to ensure timely delivery of your DIN 1480 turnbuckles, whether you need a bulk order or a custom batch. Our streamlined processes minimize delays, keeping your operations running smoothly.

After-Sales Support & Warranty

We don’t stop at the sale. Our dedicated after-sales support ensures you get the help you need throughout the life of the product. From installation guidance to troubleshooting, we’re here for you. Plus, with a strong warranty on all DIN 1480 turnbuckles, you can trust that you’re investing in durable, high-performance products backed by expert service.

OUR REVIEWS

FAQ

How to use a turnbuckle with wire?

-

Attach the Wire to One Fitting

Begin by securely attaching one end of the wire to the hook or eye fitting of the DIN 1480 turnbuckle. Ensure the wire is fastened tightly to prevent it from slipping during use. -

Connect the Opposite End of the Wire

Next, connect the opposite end of the wire to the corresponding fitting on the other side of the turnbuckle. Again, ensure the wire is securely fastened to avoid movement or slack. -

Rotate the Turnbuckle’s Central Body

Once the wire is in place, rotate the central body of the turnbuckle. Turning the body will either tighten or loosen the wire, depending on the direction. This action adjusts the tension in the wire. -

Adjust Tension to the Desired Level

Continue rotating the turnbuckle until the wire reaches the desired level of tension. This is ideal for securing cables, ropes, or wires in rigging setups, ensuring proper support and stability.

Are DIN 1480 turnbuckles compatible with other rigging components?

Yes, DIN 1480 turnbuckles are designed to be compatible with a variety of rigging components. They can be used with eye-eye, hook-eye, and hook-hook fittings that follow the same thread standards. However, always ensure that the material and size of the turnbuckle match the components you’re using to maintain strength and safety in the rigging system.

Can I use DIN 1480 turnbuckles in high-temperature environments?

DIN 1480 turnbuckles made from stainless steel are generally heat resistant but should be used within temperature limits specified by the manufacturer. For extremely high temperatures, it’s important to check the material specifications to ensure the turnbuckles will maintain their integrity. If you need turnbuckles for high-temperature applications, consult with us for suitable material options.