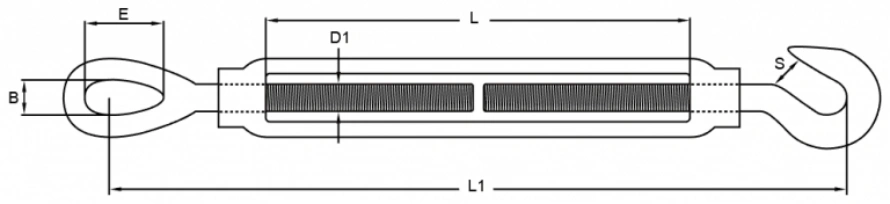

DIAGRAM

SPECIFICATIONS

| SIZE | L | L1 | S | B | E |

| in | in | in | in | in | in |

| 1/4 | 4 | 7.43 | 0.37 | 0.32 | 0.78 |

| 5/16 | 4.5 | 8.24 | 0.4 | 0.43 | 0.94 |

| 3/8 | 6 | 10.63 | 0.48 | 0.51 | 1.12 |

| 1/2 | 6 | 11.55 | 0.55 | 0.71 | 1.44 |

| 1/2 | 9 | 14.55 | 0.55 | 0.71 | 1.44 |

| 1/2 | 12 | 17.55 | 0.55 | 0.71 | 1.44 |

| 5/8 | 6 | 12.77 | 0.74 | 0.87 | 1.75 |

| 5/8 | 9 | 15.77 | 0.74 | 0.87 | 1.75 |

| 5/8 | 12 | 18.77 | 0.74 | 0.87 | 1.75 |

| 3/4 | 6 | 14.19 | 0.9 | 0.99 | 2.09 |

| 3/4 | 9 | 17.19 | 0.9 | 0.99 | 2.09 |

| 3/4 | 12 | 20.19 | 0.9 | 0.99 | 2.09 |

TRAWL BLOCK DESIGN

- Durable 304 or 316 stainless steel

- Corrosion resistant for longevity

- Precision thread for easy adjustment

- Versatile hook and eye fittings for secure connections

- Available in multiple sizes and load capacities for various needs

INSTRUCTIONS & CAUTIONS

Ensure Proper Installation

Always verify that the hook and eye turnbuckle is installed correctly within your rigging system. Improper installation could lead to unsafe tension adjustments and compromise the performance of your setup.

Check for Wear and Tear

Regularly inspect the turnbuckle for signs of wear, corrosion, or damage, especially in harsh environments like marine or industrial applications. A damaged turnbuckle can fail under tension, leading to safety hazards.

Avoid Over-Tightening

While adjusting the turnbuckle, be careful not to over-tighten. Over-tightening can damage the threads or weaken the rigging system, reducing the overall effectiveness of the turnbuckle.

Match Load Capacity

Ensure the turnbuckle’s load capacity matches the requirements of your rigging setup. Using a turnbuckle that isn’t rated for the load could cause it to fail prematurely and put the entire system at risk.

OUR ADVANTAGES

Custom-Engineered Solutions

We understand that every rigging project is unique. That’s why we offer custom-engineered turnbuckles tailored to your specific needs. Whether you need specialized sizes, materials, or configurations, we work with you to deliver the exact solution that fits your requirements, ensuring superior performance and efficiency.

Direct from Manufacturer

By sourcing directly from us, you eliminate the middleman. This means faster response times, better communication, and lower costs. We pride ourselves on delivering high-quality turnbuckles directly to our customers, ensuring you get the best value without unnecessary markups or delays.

Quality & Safety Assurance

We prioritize quality and safety in every turnbuckle we manufacture. Each piece undergoes strict testing to meet industry standards, ensuring durability and reliability in any rigging setup. When you choose our turnbuckles, you can trust they’ll perform safely and effectively, even in the most demanding environments.

After-Sales Support

Our commitment to customer satisfaction doesn’t end at the sale. We offer exceptional after-sales service, providing technical support and troubleshooting whenever you need it. We’re here to ensure your rigging system remains safe and effective long after your purchase, helping you solve any issues quickly and professionally.

OUR REVIEWS

FAQ

How do I use a turnbuckle hook and eye?

-

Attach the Hook End: Secure the hook end of the turnbuckle to one side of your rigging system.

-

Attach the Eye End: Connect the eye end to the opposite side of your rigging setup.

-

Adjust Tension: Rotate the central body of the turnbuckle to adjust the tension. This will move the hook and eye closer or further apart, tightening or loosening the rigging.

-

Secure Both Ends: Ensure both the hook and eye are securely fastened before making adjustments to avoid safety hazards.

Can I use these turnbuckles with ropes and wires?

Yes, US Type hook and eye turnbuckles are compatible with a wide range of rigging materials, including ropes, wire ropes, and cables. The hook and eye fittings provide a versatile connection, ensuring the turnbuckle works effectively with various rigging systems for both tension and load-bearing purposes.

What should I do if my trawl block is damaged?

If your trawl block shows signs of significant wear, such as cracks or a damaged sheave, it’s important to replace it immediately to prevent further issues. Don’t use a damaged block, as it can cause equipment failure or accidents. Contact us for replacement parts or a new block, and always make sure to use blocks that meet the working load limit (WLL) of your operation.

Can I order these turnbuckles with different thread types?

Yes, we offer different thread options, including standard UNC threads and metric threads, to suit international standards and your specific requirements. Whether you need a custom thread or a standard option, we’ll ensure the turnbuckles meet your rigging system’s needs.

How do I place an order for US Type hook and eye turnbuckles?

-

Contact Our Sales Team: Reach out with your specifications, including the quantity, material type, and any customization requests.

-

Get Competitive Pricing: We offer competitive pricing to ensure you get the best value for your project.

-

Benefit from Bulk Discounts: Take advantage of bulk order discounts for larger quantities.

-

Efficient Logistics: Our team ensures timely delivery and efficient logistics for your order.

-

Guidance Throughout the Process: Our team is here to help and guide you every step of the way to meet your needs.