DIAGRAM

SPECIFICATIONS

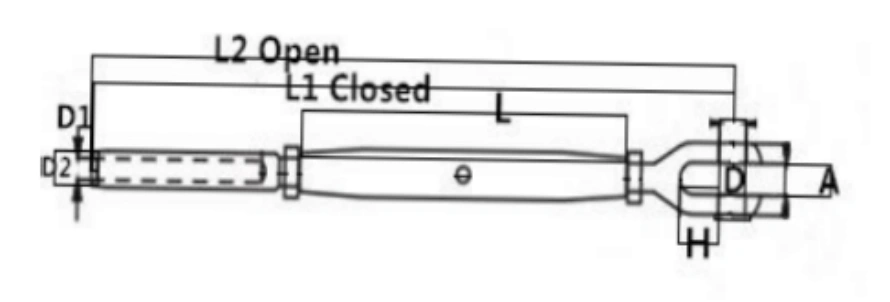

| WIRE | Size | L | L1 | L2 | A | D | D1 | D2 | H |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 2.5 | M5 | 80 | 155 | 215 | 6.5 | 5 | 2.7 | 5.5 | 10 |

| 3 | M6 | 95 | 180 | 250 | 7.5 | 6 | 3.2 | 6.35 | 10 |

| 4 | M6 | 95 | 190 | 260 | 7.5 | 6 | 4.2 | 7.5 | 10 |

| 4 | M8 | 105 | 210 | 285 | 11 | 8 | 4.2 | 7.5 | 11 |

| 5 | M8 | 105 | 215 | 290 | 11 | 8 | 5.3 | 9 | 11 |

| 5 | M10 | 125 | 240 | 330 | 12 | 9 | 5.3 | 9 | 14 |

| 6 | M10 | 125 | 255 | 345 | 12 | 9 | 6.4 | 12.6 | 14 |

| 6 | M12 | 150 | 300 | 410 | 14 | 12 | 6.4 | 12.6 | 20 |

| 8 | M12 | 150 | 316 | 426 | 14 | 12 | 8.5 | 16.0 | 20 |

| 7 | M14 | 170 | 330 | 450 | 15 | 12 | 7.5 | 14.2 | 22 |

| 8 | M16 | 190 | 370 | 510 | 17 | 16 | 8.5 | 16 | 26 |

| 10 | M16 | 190 | 380 | 520 | 17 | 16 | 10.5 | 18 | 26 |

PRODUCT FEATURES

- Made from high-quality AISI 316 stainless steel for exceptional corrosion resistance and strength

- Precision-machined design ensures long-lasting durability and performance

- Standard UNF threads provide easy and secure installation

- Perfect for wire rope tensioning, rigging, and marine applications

- Fully customizable to meet the specific requirements of your project

INSTRUCTIONS & CAUTIONS

Proper Installation

When installing the US Type Stainless Steel Swaged Turnbuckle or Jaw Swage Turnbuckle, ensure that both ends are securely attached to your rigging system. Use the correct pins and fittings and make sure everything is properly tightened. Stick to the recommended torque values to avoid damaging the components or risking safety.

Regular Inspections

It’s important to inspect the turnbuckle regularly, especially after heavy use. Look for any signs of wear, such as loose threads, rust, or cracks. By checking the turnbuckle frequently, you can catch small issues before they become bigger problems, ensuring your rigging system stays safe and reliable.

Avoid Over-Tightening

While it’s tempting to tighten the turnbuckle as much as possible, avoid over-tightening it. Too much force can damage the threads and put unnecessary strain on the rigging system. Always follow the manufacturer’s guidelines on the proper tension limits to keep everything working smoothly.

Corrosion Prevention

Even with AISI 316 stainless steel, you’ll still need to watch out for corrosion in harsh environments. For marine or outdoor use, consider cleaning and lubricating the turnbuckle periodically to help maintain its corrosion resistance. This extra step will extend the life of your turnbuckle and keep it in great shape.

OUR ADVANTAGES

Customization Options

Every project is different, and we get that. Our Swage Turnbuckles are fully customizable to your specifications. Whether it's size, finish, or thread type, we work with you to make sure the product fits your exact needs. Unlike other manufacturers, we offer more flexibility and tailored solutions to meet your unique requirements.

Direct from Manufacturer

With Powerful Machinery, you get top-tier Swage Turnbuckles directly from the manufacturer. No middlemen involved, which means faster lead times and better prices. We take care of everything in-house, ensuring you get exactly what you need without the hassle of dealing with multiple suppliers.

Quality Assurance & Certification

When you order from us, you know you’re getting a high-quality product that meets the industry’s toughest standards. We provide all necessary quality documentation and certifications, so you can be confident that our Swage Turnbuckles will perform safely and reliably in your applications.

Reliable Customer Support & After-Sales Service

Our service doesn’t stop when the order’s placed. We’re here for you with ongoing support—whether you need help with installation, maintenance tips, or have any concerns. We’re committed to ensuring your satisfaction with our Swage Turnbuckles long after delivery, so you always know you have a trusted partner.

OUR REVIEWS

FAQ

How do I adjust a turnbuckle with a hand swage?

-

Rotate the Turnbuckle Body

To adjust the tension, simply rotate the body of the turnbuckle. This action will either tighten or loosen the wire rope depending on the direction you turn it. -

Manual Adjustments

The hand swage design allows you to make adjustments manually, giving you full control over the tensioning process. -

Achieve Perfect Tension

Use the hand swage to fine-tune the tension on your wire rope, helping you maintain the optimal performance of your rigging system. -

Tool-Free Operation

One of the advantages of a hand swage is that it doesn’t require tools, making it quick and easy to adjust the tension as needed. -

Efficient Adjustment

This method offers an efficient way to make small adjustments without the need for additional equipment, keeping your rigging setup in top condition.

What is the small hole on a swage turnbuckle for?

The small hole on a swage turnbuckle is for securing the turnbuckle with a pin or bolt. This ensures that the turnbuckle stays in place and doesn’t rotate or slip under tension. It’s an essential feature for safety, especially in high-stress applications where loose turnbuckles can cause damage to your rigging system. This feature helps maintain the integrity of the entire setup.

How do I install a JIS Type Stainless Steel Swage Turnbuckle?

-

Attach the Turnbuckle to Your Rigging System

Begin by connecting the turnbuckle to your rigging system using the appropriate fittings, such as eye or jaw ends. Ensure the turnbuckle is positioned correctly for the application. -

Secure with Pins or Bolts

Secure the turnbuckle in place by using the appropriate pins or bolts. This ensures that the turnbuckle stays firmly attached to the rigging system. -

Rotate the Body to Adjust Tension

Once secured, rotate the turnbuckle body to either tighten or loosen the tension on the wire rope, adjusting it to your desired level. -

Check Alignment and Connection

Before use, double-check that everything is tightly connected and aligned properly to ensure safe and effective operation. -

Consult Technical Support if Needed

If the installation is more complex or you need further assistance, don’t hesitate to reach out to our technical support team for guidance and recommendations.

What size swage turnbuckle should I use for my project?

The size of the swage turnbuckle you need depends on the diameter of your wire rope and the required tension load for your project. Larger projects with heavy loads will require bigger turnbuckles, while lighter-duty applications need smaller ones. Our sales team can help you determine the best size for your specific needs to ensure optimal performance and safety.

How do I maintain the swage turnbuckles?

-

Inspect Regularly for Wear, Rust, or Damage

Periodically check your JIS Type Swage Turnbuckles for any signs of wear, rust, or damage. Addressing any issues early can prevent more severe problems down the line. -

Clean with Fresh Water

After exposure to saltwater or dirt, clean the turnbuckles with fresh water. This removes salt and debris, helping to maintain their appearance and functionality. -

Lubricate the Threads

To prevent corrosion and ensure smooth adjustments, lubricate the threads of the turnbuckle periodically. This will keep the components moving freely and protect them from wear. -

Keep Turnbuckles Well-Maintained

Regular maintenance, including cleaning and lubrication, helps prolong the lifespan of your swage turnbuckles, ensuring they continue to perform at their best.

How do I adjust the tension on a JIS Type Swage Turnbuckle?

-

Rotate the Turnbuckle Body

To adjust the tension, simply rotate the body of the turnbuckle. Turning it clockwise will tighten the connection, while turning it counterclockwise will loosen it. -

Increase or Decrease Tension

This rotation will either increase or decrease the tension on your wire rope or rigging system, depending on the direction you turn the body. -

Check Tension Range

Always ensure the tension is within the recommended range for your specific application. Over-tightening or under-tightening could damage the turnbuckle or other rigging components. -

Avoid Damage to Rigging Components

By monitoring and adjusting the tension carefully, you can ensure that your rigging system remains safe and fully operational without risking damage to the turnbuckle or associated hardware.

What is the difference between a jaw and eye turnbuckle?

A jaw turnbuckle has a “U”-shaped fitting that can be secured using a pin or bolt, while an eye turnbuckle has a closed loop, often used for connecting to a hook or other rigging hardware. The choice between jaw and eye turnbuckles depends on the type of connection you need for your rigging system. Our team can help you choose the right option based on your project requirements.