DIAGRAM

SPECIFICATIONS

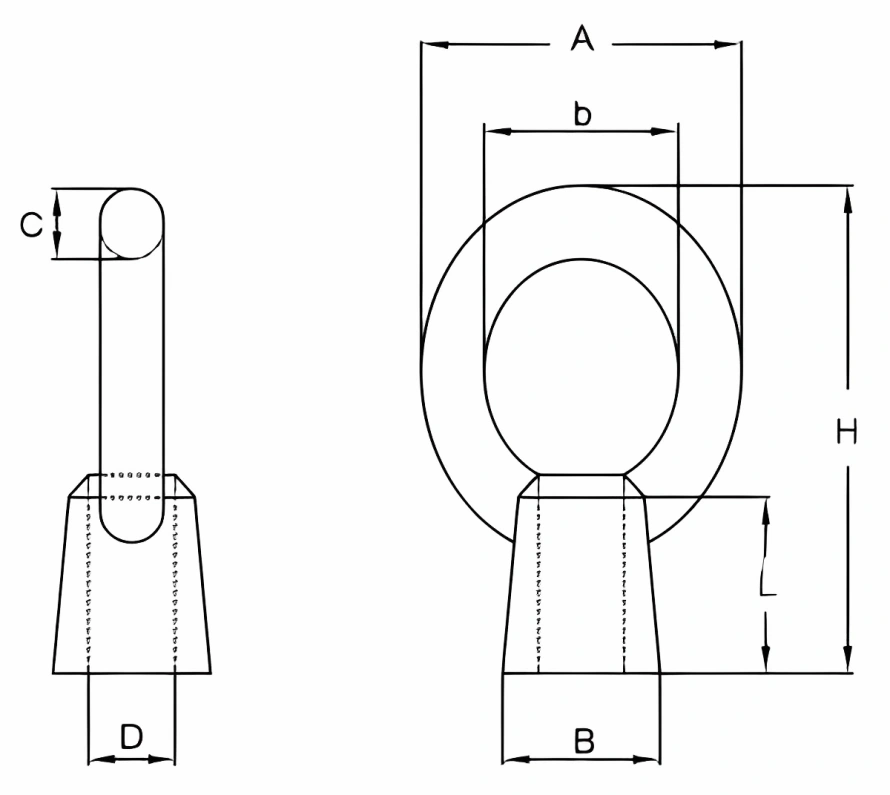

| ITEM NO | A | C | D | H | L | B | b | WT |

| mm | mm | mm | mm | mm | mm | mm | KGS | |

| PF0053-A/B0006 | 26 | 5 | M6 | 33 | 13 | 12 | 16 | 0.015 |

| PF0053-A/B0008 | 32 | 6 | M8 | 39 | 13.5 | 14.5 | 20 | 0.025 |

| PF0053-A/B0010 | 40 | 7.5 | M10 | 48 | 16.5 | 19 | 25 | 0.056 |

| PF0053-A/B0012 | 49 | 9.5 | M12 | 60 | 21.5 | 22.5 | 30 | 0.102 |

| PF0053-A/B0016 | 57.5 | 12 | M16 | 70 | 26 | 28 | 34 | 0.184 |

| PF0053-A/B0020 | 70 | 15 | M20 | 81.5 | 30 | 35.5 | 40 | 0.36 |

PRODUCT FEATURES

- Material: AISI 304 / AISI 316 stainless steel

- Standard: JIS 1169

- Finish: High-polished and electric polished

- Application: Ideal for threaded rod use in architectural, marine, and rigging applications

INSTRUCTIONS & CAUTIONS

Proper Installation

Always ensure the eye nut is fully threaded onto the rod or bolt, making firm contact between the mating surfaces. It’s important that the nut is tightened securely to prevent any loosening during use.

Check Load Capacity

Do not exceed the rated load capacity for the eye nut. It’s designed for use with threaded rods, and overloading can cause failure. Always confirm that the load is within the specifications for safe operation.

Avoid Overhead Lifting

The JIS stainless steel lifting eye nut is not designed for overhead lifting or carrying loads over people. Always follow the manufacturer’s guidelines and use proper lifting equipment when handling heavy loads.

Regular Inspection

Inspect the eye nut regularly for signs of wear, corrosion, or damage. Ensure the threads are clean and intact, and that the nut is free from cracks. Regular checks help maintain its effectiveness and safety in your rigging system.

OUR ADVANTAGES

Custom-Engineered Solutions

We offer tailor-made products designed to meet your specific project needs. Our team works closely with you to provide customized lifting eye nuts, ensuring the best fit for your applications. From sizes to finishes, we deliver solutions that help you meet the unique demands of your rigging and lifting projects.

Quality & Safety Standards

At Powerful Machinery, we prioritize quality and safety in every product. Our JIS Stainless Steel Lifting Eye Nuts are made from corrosion-resistant AISI 304 or AISI 316 stainless steel, ensuring longevity and reliability. With strict adherence to international standards, we deliver products you can trust for critical lifting and rigging applications.

One-Stop Sourcing

We simplify your sourcing process. Whether you need bulk orders or custom-engineered solutions, Powerful Machinery is your one-stop shop for lifting eye nuts and other rigging components. With a broad range of sizes and finishes available, we meet all your requirements in one place, reducing lead times and improving efficiency.

Industry-Leading Customer Support

Our customer support doesn’t end after the sale. We provide expert guidance, fast response times, and ongoing assistance with installation and maintenance. Our after-sales service ensures that any questions or concerns are quickly addressed, keeping your operations running smoothly and minimizing downtime.

OUR REVIEWS

FAQ

Are there any maintenance tips for JIS Stainless Steel Lifting Eye Nuts?

-

Regular Inspection:

Inspect your JIS Stainless Steel Lifting Eye Nuts frequently for any signs of wear, corrosion, or cracks. Catching issues early ensures safe use and longer lifespan. -

Clean Regularly:

Clean the eye nuts periodically, especially if used in harsh or marine environments. This helps remove debris, salt buildup, or any corrosive elements that could affect the nut’s performance. -

Lubricate Threads:

Apply a thin layer of lubricant on the threads to maintain smooth operation and reduce the risk of rust or friction. Lubrication also ensures easier adjustments when needed. -

Tighten Securely:

Always ensure that the threads are intact, and the nut is securely tightened before each use. This helps prevent any slippage or unsafe usage during rigging operations.

What is the advantage of using stainless steel for lifting eye nuts?

Stainless steel, particularly AISI 304 and AISI 316, offers exceptional resistance to corrosion, which makes it ideal for outdoor, marine, and high-moisture environments. This material provides strength, durability, and long-lasting performance, making it a safer and more reliable option than other metals, especially when dealing with heavy loads or high-stress conditions.

How do I know if the JIS Stainless Steel Lifting Eye Nut will fit my rigging system?

To ensure a proper fit, check the thread specifications of your rigging system. The thread diameter and length should match the corresponding dimensions of the JIS Stainless Steel Lifting Eye Nut. Our products come with precision-cut metric threads, so they fit seamlessly with standard threaded rods and bolts. If you’re unsure, our team can assist in verifying compatibility.

What should I do if I receive damaged JIS Stainless Steel Lifting Eye Nuts?

If you receive a damaged product, please contact our customer service team immediately. We offer easy and quick returns or replacements, depending on the issue. Our goal is to ensure that your order meets your expectations, and we’ll work with you to resolve any problems swiftly. Your satisfaction is our priority.

How long does it take to receive a wholesale order of JIS Stainless Steel Lifting Eye Nuts?

The delivery time for wholesale orders depends on the quantity and customization requirements. Typically, we process and ship orders within 5-7 business days. For large or custom orders, we’ll provide a clear timeline and tracking information so you can plan accordingly. We prioritize efficient logistics to ensure timely delivery, no matter the size of your order.