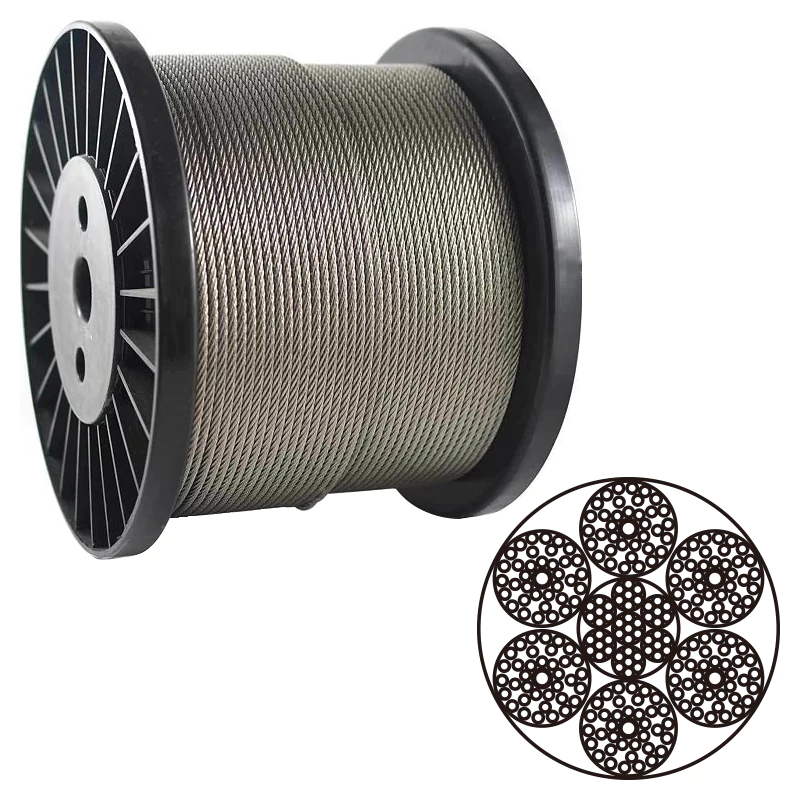

Technical Specifications: 6×19 Steel Wire Rope

The 6×19 class of steel wire rope is the undisputed industry standard for hoisting and general-purpose applications, engineered to provide the perfect equilibrium between fatigue resistance (flexibility) and abrasion resistance (durability). This exceptional balance ensures a long and reliable service life in dynamic environments.

To empower our distributors to meet any customer specification, from the routine to the extreme, we offer this workhorse rope in three distinct core configurations, creating a clear performance hierarchy:

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE(MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 3 | 3.11 | 3.03 | 3.43 | 4.34 | 4.69 | 4.61 | 4.99 | 4.89 | 5.29 | 5.17 | 5.59 | 5.41 | 5.85 |

| 4 | 5.54 | 5.39 | 6.1 | 7.71 | 8.34 | 8.2 | 8.87 | 8.69 | 9.4 | 9.19 | 9.93 | 9.62 | 10.4 |

| 5 | 8.65 | 8.43 | 9.53 | 12 | 13 | 12.8 | 13.9 | 13.6 | 14.7 | 14.4 | 15.5 | 15 | 16.2 |

| 6 | 12.5 | 12.1 | 13.7 | 17.4 | 18.8 | 18.5 | 20 | 19.6 | 21.2 | 20.7 | 22.4 | 21.6 | 23.4 |

| 7 | 17 | 16.5 | 18.7 | 23.6 | 25.5 | 25.1 | 27.2 | 26.6 | 28.8 | 28.1 | 30.4 | 29.4 | 31.8 |

| 8 | 22.1 | 21.6 | 24.4 | 30.8 | 33.4 | 32.8 | 35.5 | 34.8 | 37.6 | 36.7 | 39.7 | 38.5 | 41.6 |

| 9 | 28 | 27.3 | 30.9 | 39 | 42.2 | 41.5 | 44.9 | 44 | 47.6 | 46.5 | 50.3 | 48.7 | 52.7 |

| 10 | 34.6 | 33.7 | 38.1 | 48.2 | 52.1 | 51.3 | 55.4 | 54.3 | 58.8 | 57.4 | 62.1 | 60 | 65 |

| 11 | 41.9 | 40.8 | 46.1 | 58.3 | 63.1 | 62 | 67.1 | 65.8 | 71.1 | 69.5 | 75.1 | 72.8 | 78.7 |

| 12 | 49.8 | 48.5 | 54.9 | 69.4 | 75.1 | 73.8 | 79.8 | 78.2 | 84.6 | 82.7 | 89.4 | 86.6 | 93.7 |

| 13 | 58.5 | 57 | 64.4 | 81.5 | 88.1 | 86.6 | 93.7 | 91.8 | 99.3 | 97 | 105 | 101 | 110 |

| 14 | 67.8 | 66.1 | 74.7 | 94.5 | 102 | 100 | 109 | 107 | 115 | 113 | 122 | 118 | 127 |

| 16 | 88.6 | 86.3 | 97.5 | 123 | 133 | 131 | 142 | 139 | 150 | 147 | 159 | 154 | 166 |

| 18 | 112 | 109 | 123 | 156 | 169 | 166 | 180 | 176 | 190 | 186 | 201 | 195 | 210 |

| 20 | 138 | 135 | 152 | 193 | 208 | 205 | 222 | 217 | 235 | 230 | 248 | 240 | 260 |

| 22 | 167 | 163 | 184 | 233 | 252 | 248 | 268 | 263 | 284 | 278 | 300 | 291 | 316 |

| 24 | 199 | 194 | 219 | 278 | 300 | 295 | 319 | 313 | 338 | 331 | 358 | 346 | 374 |

| 26 | 234 | 228 | 258 | 326 | 352 | 347 | 375 | 367 | 397 | 388 | 420 | 406 | 440 |

| 28 | 271 | 264 | 299 | 378 | 409 | 402 | 435 | 426 | 461 | 450 | 487 | 471 | 510 |

| 30 | 311 | 303 | 343 | 434 | 469 | 461 | 499 | 489 | 529 | 517 | 559 | 541 | 585 |

| 32 | 354 | 345 | 390 | 494 | 534 | 525 | 568 | 556 | 602 | 588 | 636 | 616 | 666 |

| 34 | 400 | 390 | 440 | 557 | 603 | 593 | 641 | 628 | 679 | 664 | 718 | 695 | 752 |

| 36 | 448 | 437 | 494 | 625 | 676 | 664 | 719 | 704 | 762 | 744 | 805 | 780 | 843 |

| 38 | 500 | 487 | 550 | 696 | 753 | 740 | 801 | 785 | 849 | 829 | 896 | 868 | 940 |

| 40 | 554 | 539 | 610 | 771 | 834 | 820 | 887 | 869 | 940 | 919 | 993 | 962 | 1041 |

| 42 | 610 | 594 | 672 | 850 | 919 | 904 | 978 | 959 | 1040 | 1010 | 1100 | 1061 | 1147 |

| 44 | 670 | 652 | 738 | 933 | 1010 | 993 | 1070 | 1050 | 1140 | 1110 | 1200 | 1164 | 1260 |

| 46 | 732 | 713 | 806 | 1020 | 1100 | 1080 | 1170 | 1150 | 1240 | 1210 | 1310 | 1273 | 1376 |

6×19+FC Steel Wire Rope

This is the most flexible and widely used configuration. The fiber core provides excellent elasticity, is easy to handle, and spools well on single-layer drums. It is the economical and reliable choice for a multitude of applications, including general-purpose cranes, winches, and overhead door cables, where extreme load or crushing is not the primary concern.

6×19+IWS Steel Wire Rope

As a significant step-up from the fiber core, the IWS configuration features a single strand of wire as its core. This provides substantially more strength, greater crush resistance, and better support for the outer strands, while retaining more flexibility than an IWR. It bridges the gap for applications like container cranes, some drilling lines, and hoist ropes that require higher performance than FC can offer.

6×19+IWR Steel Wire Rope

Representing the pinnacle of strength and resilience, the IWR configuration uses a separate, smaller wire rope as its core. This design offers the highest breaking strength, maximum resistance to crushing and heat, and superior structural stability. It is the essential choice for the most demanding and critical operations, including main hoist lines on heavy-duty cranes, boom pendants, and any application where safety and performance under extreme load are paramount.