DIAGRAM

SPECIFICATIONS

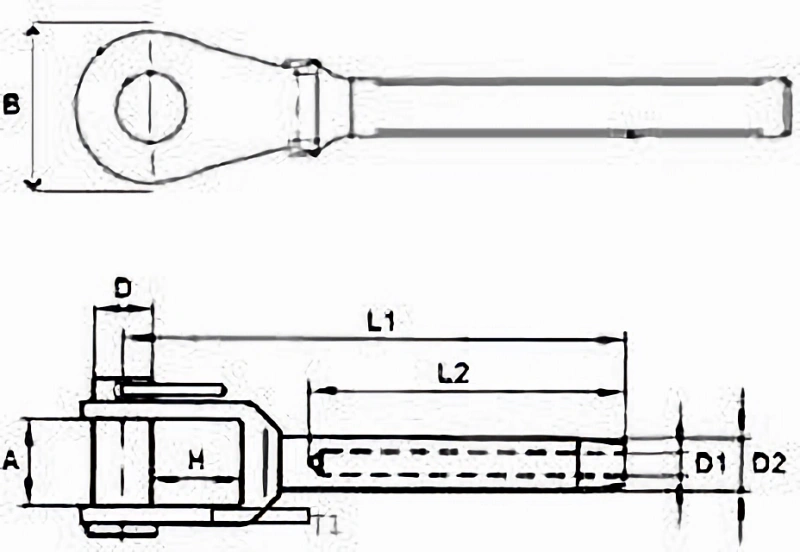

| ITEM NO | WIREΦ | L1 | L2 | A | D | H | B | T1 | B1 | D1 | D2 | WT |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KGS | |

| HF0276-A0205 | 2.5 | 55 | 24 | 6.5 | 5 | 10 | 13 | 3 | 10 | 2.7 | 5.5 | 0.0195 |

| HF0276-A0003 | 3 | 65 | 32 | 7.5 | 6 | 10 | 14 | 3 | 10 | 3.3 | 6.35 | 0.02 |

| HF0276-A0004 | 4 | 77 | 40 | 11 | 8 | 11 | 18.5 | 3 | 12 | 4.3 | 7.5 | 0.046 |

| HF0276-A0005 | 5 | 88 | 57 | 12 | 9 | 14 | 21 | 4 | 13.5 | 5.3 | 9 | 0.072 |

| HF0276-A0006 | 6 | 106 | 63 | 14 | 12 | 20 | 26 | 5 | 18.5 | 6.4 | 12.6 | 0.109 |

| HF0276-A0007 | 7 | 116 | 70 | 15 | 12 | 22 | 26.5 | 5 | 20.5 | 7.4 | 14.2 | 0.15 |

| HF0276-A0008 | 8 | 145 | 85 | 17 | 16 | 26 | 36 | 6 | 24.5 | 8.4 | 16 | 0.246 |

| HF0276-A0010 | 10 | 150 | 90 | 20 | 19 | 30 | 45.5 | 6 | 29.5 | 10.5 | 18 | 0.471 |

| HF0276-A0012 | 12 | 195 | 105 | 23 | 19 | 35 | 45.5 | 6 | 29.5 | 12.6 | 20 | 0.595 |

PRODUCT FEATURES

-

Made from AISI 316 stainless steel for corrosion resistance

-

Precision cast turnbuckle body with forged eye and hook

-

Easy-to-adjust rotating mechanism for efficient tensioning

-

Ideal for marine and outdoor projects, including sailboat rigging

-

Available in sizes 2.5mm to 12mm

INSTRUCTIONS & CAUTIONS

Proper Installation

Make sure the swage jaw terminal is installed securely by properly swaging the terminal onto the wire rope. A correct fit is essential to maintain strength and performance. Always double-check that the terminal is tightly secured before use, especially for marine or industrial setups.

Handling the Material

Though AISI 316 stainless steel is highly resistant to corrosion, avoid rough handling that could lead to damage. Store the terminals in a dry, clean area away from extreme weather conditions. Regularly inspect for wear and tear, particularly in salty or corrosive environments like marine applications.

Adjusting Tension

The swage jaw terminal features a rotating mechanism that makes tensioning easier. Just be careful to adjust it slowly and evenly. Over-tightening can lead to stress and potential failure. Ensuring proper tension helps keep the system secure and functional.

Know the Limits

These swage jaw terminals are designed for static use and are not intended for lifting or heavy-duty commercial applications. They work best for outdoor projects and environments like sailboat rigging. Always use the terminal within its intended scope to maintain safety and performance.

OUR ADVANTAGES

Tailored Solutions for Your Needs

At Powerful Machinery, we understand every project is unique. That’s why we offer custom-engineered solutions to fit your exact specifications. Whether you need specialized designs, materials, or finishes, our team works with you every step of the way to deliver exactly what you need, ensuring your project runs smoothly and on time.

Competitive Pricing and Flexibility

We offer some of the most competitive prices in the market without compromising on quality. Thanks to our streamlined production and sourcing processes, we provide cost-effective solutions, whether you're buying in bulk or need a custom order. Plus, with our flexible terms, we cater to your specific budget and volume needs, ensuring you get the best value.

Industry-Leading Customer Service

We pride ourselves on delivering exceptional customer service. Our team is available to assist you from the first inquiry to after-sales support. We don’t just sell products—we build lasting relationships with our customers, ensuring that any concerns are addressed promptly and professionally. You can count on us for quick responses and reliable solutions.

Reliable, Fast Delivery

We know that timing is critical. That’s why our efficient logistics and transportation network ensures your orders arrive when you need them. Whether you're placing a large wholesale order or need a quick restock, we provide fast and reliable delivery options worldwide, minimizing downtime and keeping your business running.

OUR REVIEWS

FAQ

What’s the difference between swage jaw terminals and other wire rope terminals?

Swage jaw terminals provide a clean, secure connection by swaging the terminal onto the wire rope, making them ideal for high-tension applications. Compared to other terminals like threaded or bolt-on types, swage jaw terminals are often more compact and offer better performance in spaces where other options might be too bulky.

How do I place a bulk order for stainless steel swage jaw terminals?

-

Contact Our Sales Team: Reach out to us with the quantity, size, and finish specifications for your order.

-

Get a Detailed Quote: We’ll provide you with an accurate price and delivery timeline based on your requirements.

-

Competitive Pricing: For large orders, we offer competitive pricing to ensure you get the best value.

-

Flexible Shipping Options: We offer flexible shipping methods to meet your needs efficiently, whether by air or sea.

What’s the lead time for receiving my order?

Lead time depends on the size and complexity of your order. Standard orders typically ship within 5-7 business days, while bulk or custom orders may take a bit longer. We’ll provide you with an estimated shipping timeline once your order details are confirmed.

Are these terminals weather-resistant?

Yes, stainless steel swage jaw terminals are specifically designed to withstand tough weather conditions. The AISI 316 stainless steel construction provides excellent resistance against moisture, UV exposure, and saltwater, making these terminals perfect for outdoor use in harsh climates.

What shipping options are available for bulk orders?

We offer both sea and air shipping options for large orders. Sea shipping is typically used for bulk orders, and we pack everything securely to ensure it arrives safely. For smaller, urgent orders, we also offer air shipping. We work with trusted logistics providers to ensure on-time delivery.