Product Specifications

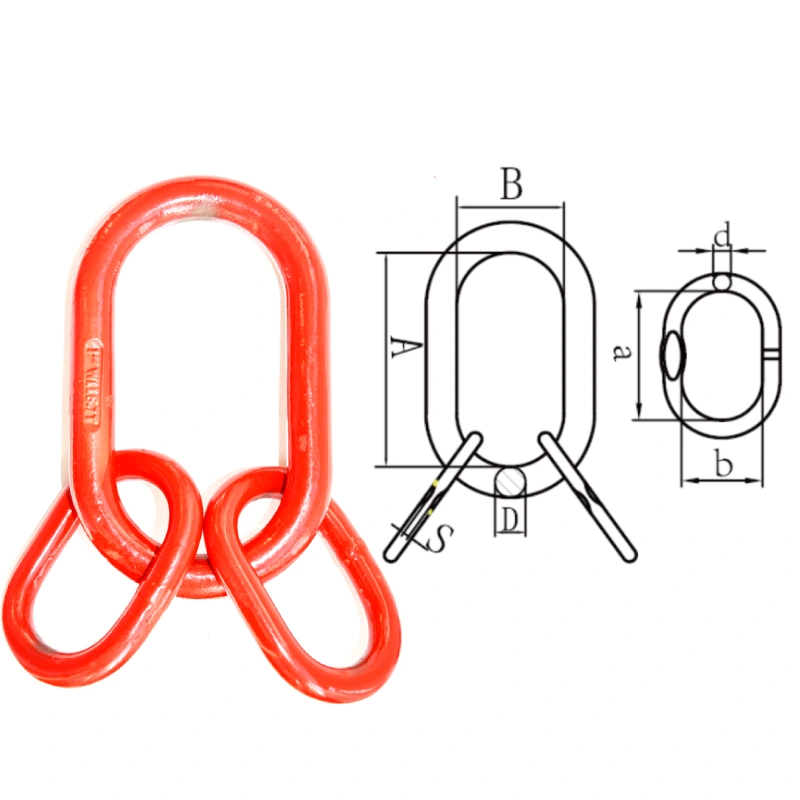

G80 U.S. TYPE A-345 FORGED MASTER LINK ASSEMBLY

| SIZE | WEIGHT KG/PC |

DIMENSIONS (MM) | DIMENSIONS (MM) | CHAIN SIZE & WORKING LOAD LIMIT (TON) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | D | a | b | d | CHAIN SIZE IN. |

3 OR 4 LEG WLL(TON) |

FOR WOPE WLL(TON) |

||

| 3/4″ | 1.55 | 140 | 70 | 20 | 85 | 40 | 14 | 1/4″ | 3.15 | 5.6 |

| 5/16″ | 4.25 | |||||||||

| 7/8″ | 2.18 | 160 | 95 | 22 | 85 | 40 | 14 | 5/16″ | 4.25 | 6.9 |

| 3/8″ | 6.7 | |||||||||

| 1″ | 3.29 | 178 | 89 | 25 | 100 | 60 | 18 | 3/8″ | 6.7 | 11.8 |

| 1-1/4″ | 7.18 | 220 | 110 | 32 | 100 | 60 | 22 | 1/2″ | 11.2 | 17.7 |

| 5/8″ | 17 | |||||||||

| 1-1/2″ | 12.91 | 267 | 135 | 38 | 180 | 100 | 30 | 5/8″ | 17 | 27.7 |

| 3/4″ | 23.6 | |||||||||

| 1-3/4″ | 21.25 | 305 | 152 | 45 | 180 | 100 | 32 | 3/4″ | 23.6 | 38.5 |

| 7/8″ | 31.5 | |||||||||

| 2″ | 30.34 | 356 | 178 | 50 | 180 | 100 | 38 | 7/8″ | 31.5 | 46.5 |

| 2-1/2″ | 64.4 | 406 | 203 | 64 | 355 | 178 | 51 | 1″ | 45 | 72.6 |

| 2-3/4″ | 89 | 406 | 241 | 70 | 406 | 203 | 57 | 1-1/4″ | 67 | 98.4 |

Note: WLL = Working Load Limit. All dimensions are in millimeters (MM) and weights in kilograms (KG).

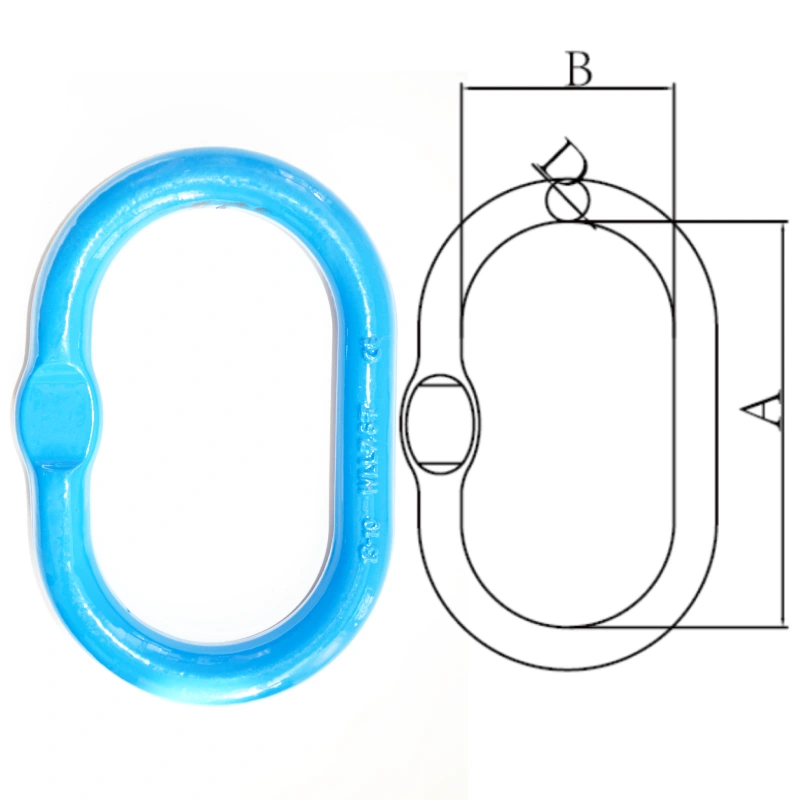

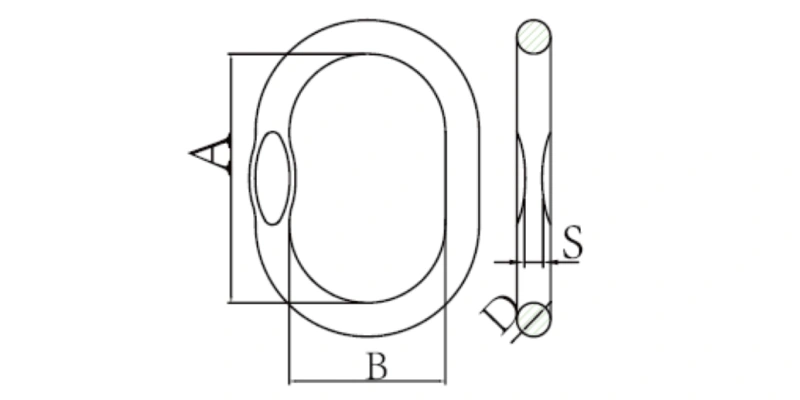

Products Diagrams

The G80 U.S. Type A-345 Forged Master Link Assembly is engineered with a forged oblong shape, paired with welded sub-links for added stability. This structure provides balanced load distribution, reducing stress points and increasing overall lifting reliability for multi-leg chain sling systems.

Application Viewpoint

In real-world lifting operations, the A-345 Master Link Assembly connects easily with chains and hooks. It is designed for quick, safe integration into rigging systems. Its versatility ensures reliable performance across construction, marine, and mining environments, helping users handle heavy-duty tasks efficiently with minimal downtime.

Material Specification

Grade: Forged from Grade 80 alloy steel, ensuring exceptional strength and meeting international lifting standards.

Finish: Supplied with powder-coated or painted finish, offering strong resistance against corrosion and surface wear.

Attachment: Designed for multi-leg chain sling assemblies, improving flexibility and safety in lifting operations.

Hook Type: Compatible with G80 hooks and other rigging hardware, ensuring universal adaptability.

Material: Made from high-grade alloy steel, ensuring ductility, toughness, and reliable load performance.

Application

Construction Industry

Used for lifting beams, machinery, and concrete blocks, ensuring safe and reliable multi-leg sling connections in construction projects.

Marine & Offshore

Provides secure load handling for shipbuilding, offshore rigs, and cargo lifting in harsh marine environments with salt and humidity.

Mining Industry

Used for heavy-duty lifting of mining equipment, machinery, and conveyor parts, built to withstand extreme industrial conditions.

Advantages

Corrosion & Finish Protection

Protective coating shields against rust, ensuring long-term reliability in outdoor, marine, and industrial environments where durability matters most.

Customization & Traceability

Available in standard and custom sizes, each assembly carries batch markings, ensuring compliance, safety checks, and full traceability for industrial buyers.

Load Control & Durability

Forged Grade 80 steel provides high strength, ensuring controlled load handling and maximum durability in repetitive heavy lifting operations.

Bulk Capacity & Lead Time

We support large-volume orders with strong production capacity and short lead times, helping distributors and contractors meet deadlines and reduce procurement risks.

Supporting Products

G80 Alloy Chain

Steel Wire Rope

High-strength rope for versatile lifting and rigging solutions in construction and marine.

Pulleys & Sheaves

Engineered to redirect loads safely, reducing stress on lifting assemblies.

FAQ

What is a G80 U.S. Type A-345 Forged Master Link Assembly used for

It is the main connecting component in rigging systems. This assembly links chains, hooks, and lifting devices, enabling safe multi-leg sling lifting. It is widely used in construction, marine, and mining industries where heavy-duty load handling is required.

How does it comply with ASME B30.26?

The A-345 assembly meets or exceeds ASME B30.26 requirements for identification, ductility, design factor, proof load, and temperature performance. Buyers can trust that every product is certified safe and built to international standards.

Do you offer custom sizes and designs?

Yes. As a manufacturer, we supply both standard and customized sizes to fit different load requirements. Custom solutions are available for special applications, helping distributors and contractors secure tailored lifting systems.

Can this product be used with other rigging hardware?

Yes. The G80 U.S. Type A-345 Master Link Assembly is compatible with chains, G80 hooks, and other rigging components. Its universal design ensures seamless integration in lifting systems.

Do you support bulk supply and international shipping?

We specialize in bulk manufacturing, quick lead times, and international shipping. Our global network supports distributors, wholesalers, and large contractors with consistent quality and reliable supply.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.