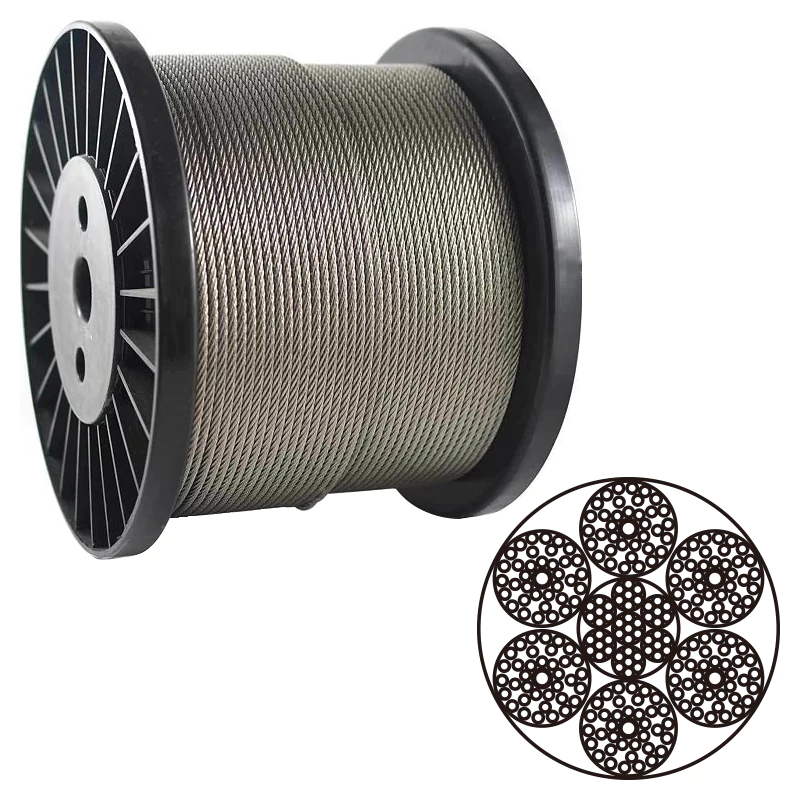

Technical Specifications for 8×19S Elevator Steel Wire Rope

The 8x19S is a premier wire rope designed and manufactured to meet the stringent safety and performance standards of the elevator industry. Its eight-strand construction is the key to its superior performance, providing a broader contact surface on the traction sheave. This significantly reduces the pressure on both the rope and the expensive sheave grooves, leading to a longer operational life for the entire system, reduced vibration, and an exceptionally quiet ride—a critical factor in passenger experience. The Seale (S) strand design further enhances durability with its large outer wires, providing excellent resistance to the abrasive wear of continuous operation.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | |||||||||

| 1570 | 1670 | 1770 | 1870 | ||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||

| 8 | 22.1 | 21.4 | 27 | 29.4 | 34.7 | 31.3 | 36.9 | 33.1 | 39.2 | 35 | 41.4 |

| 9 | 28 | 27.1 | 34.2 | 37.3 | 44 | 39.6 | 46.7 | 42 | 49.6 | 44.3 | 52.4 |

| 10 | 34.6 | 33.4 | 42.2 | 46 | 54.3 | 48.9 | 57.7 | 51.8 | 61.2 | 54.7 | 64.7 |

| 11 | 41.9 | 40.4 | 51.1 | 55.6 | 65.7 | 59.2 | 69.9 | 62.7 | 74.1 | 66.2 | 78.2 |

| 12 | 49.9 | 48 | 60.8 | 66.2 | 78.2 | 70.4 | 83.2 | 74.6 | 88.1 | 78.8 | 93.1 |

| 13 | 58.5 | 56.4 | 71.3 | 77.7 | 91.8 | 82.6 | 97.6 | 87.6 | 103 | 92.5 | 109 |

| 14 | 67.9 | 65.4 | 82.7 | 90.1 | 106 | 95.9 | 113 | 101 | 120 | 107 | 126 |

| 16 | 88.7 | 85.4 | 108 | 117 | 139 | 125 | 147 | 132 | 156 | 140 | 165 |

| 18 | 112 | 108 | 137 | 149 | 176 | 158 | 187 | 168 | 198 | 177 | 209 |

| 20 | 139 | 133 | 169 | 184 | 217 | 195 | 231 | 207 | 244 | 219 | 258 |

| 22 | 168 | 162 | 204 | 222 | 262 | 236 | 279 | 251 | 296 | 265 | 313 |

| 24 | 199 | 192 | 243 | 264 | 312 | 281 | 332 | 298 | 352 | 315 | 372 |

| 26 | 234 | 226 | 285 | 310 | 367 | 330 | 390 | 350 | 413 | 370 | 437 |

| 28 | 271 | 262 | 330 | 360 | 425 | 384 | 453 | 406 | 480 | 429 | 507 |

| 30 | 312 | 300 | 380 | 414 | 488 | 440 | 520 | 466 | 551 | 493 | 582 |

| 32 | 355 | 342 | 432 | 471 | 556 | 501 | 591 | 531 | 627 | 561 | 662 |

| 34 | 400 | 386 | 488 | 532 | 628 | 565 | 668 | 600 | 707 | 633 | 747 |

| 36 | 448 | 432 | 546 | 596 | 704 | 634 | 758 | 672 | 793 | 710 | 838 |

| 38 | 500 | 482 | 609 | 664 | 784 | 706 | 834 | 748 | 884 | 791 | 934 |

| 40 | 554 | 534 | 675 | 736 | 869 | 782 | 924 | 830 | 979 | 876 | 1030 |

| 42 | 611 | 589 | 744 | 811 | 958 | 863 | 1010 | 914 | 1080 | 966 | 1141 |

| 44 | 670 | 646 | 817 | 890 | 1051 | 947 | 1110 | 1000 | 1180 | 1060 | 1252 |

| 46 | 733 | 706 | 893 | 973 | 1140 | 1030 | 1222 | 1090 | 1290 | 1150 | 1360 |

| 50 | 865 | 835 | 1055 | 1155 | 1358 | 1223 | 1444 | 1296 | 1531 | 1369 | 1617 |

To cater to the full range of elevator applications, from residential buildings to skyscrapers, we offer two distinct core types:

8x19S+FC Elevator Steel Wire Rope

This is the industry standard for ensuring maximum passenger comfort. The natural fiber core acts as an effective vibration and noise damper, providing the smoothest possible ride. It also serves as a lubricant reservoir, protecting the rope from the inside out. This configuration is the ideal choice for low to mid-rise residential buildings, hotels, and commercial offices where ride quality is paramount.

8x19S+IWR Elevator Steel Wire Rope

This is the high-performance solution for the most demanding elevator applications. The steel core provides a higher breaking strength and, most importantly, minimal constructional stretch over the rope’s life. This low-stretch characteristic is crucial for maintaining precise floor leveling in high-rise and super-tall buildings, and for handling the immense loads of heavy-duty freight elevators. It is the essential specification for high-speed, high-travel, and heavy-load systems.