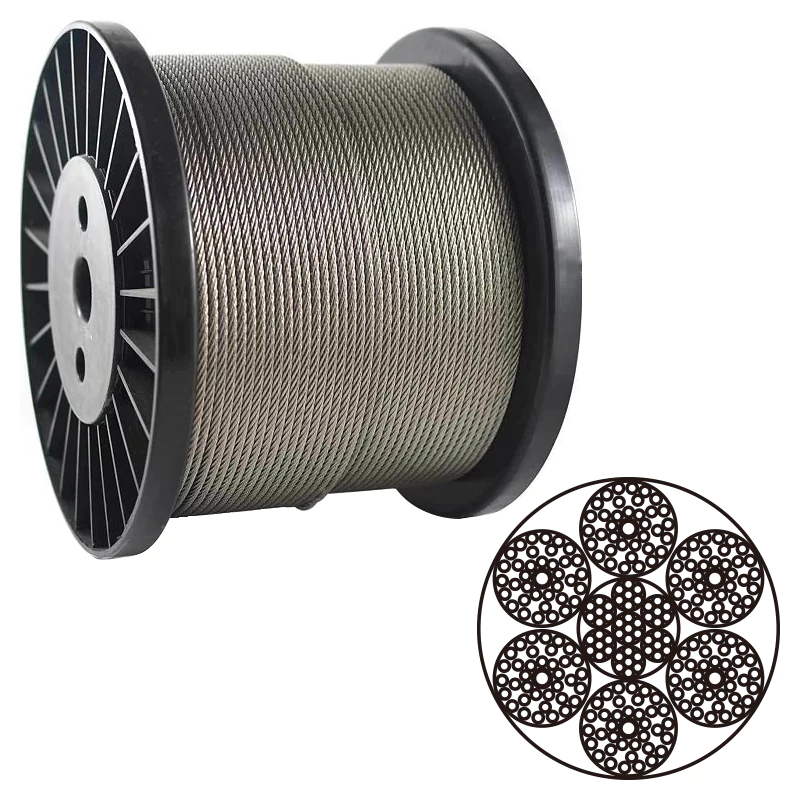

Technical Specifications for 8×41SW Steel Wire Rope

The 8x41WS is the ultimate expression of wire rope technology, engineered for visionary projects that push the boundaries of mechanical design. It is a bespoke solution for the most extreme dynamic applications, where performance is defined by survival under millions of severe, high-speed bending cycles. The construction features the highest density of ultra-fine wires in a sophisticated Warrington Seale strand, meticulously designed to operate under bending conditions simply not viable for any other steel rope. Its purpose is to enable the creation of more compact, faster, and more efficient lifting systems.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 8 | 22.98 | 22 | 27.9 | 29.3 | 34.7 | 31.2 | 36.9 | 33.1 | 39.1 | 35 | 41.3 | 36.7 | 43.4 |

| 9 | 29 | 27.8 | 35.3 | 37.1 | 43.9 | 39.5 | 46.7 | 41.9 | 49.5 | 44.3 | 52.3 | 46.5 | 54.9 |

| 10 | 35.9 | 34.4 | 43.6 | 45.8 | 54.2 | 48.8 | 57.6 | 51.7 | 61.1 | 54.7 | 64.6 | 57.4 | 67.8 |

| 11 | 43.3 | 42.6 | 52.7 | 55.5 | 65.5 | 59 | 69.7 | 62.6 | 73.9 | 66.2 | 78.2 | 69.5 | 82 |

| 12 | 51.5 | 49.5 | 62.8 | 66 | 78 | 70.2 | 83 | 74.5 | 88 | 78.7 | 93 | 82.7 | 97.6 |

| 13 | 60.4 | 58.1 | 73.6 | 77.5 | 91.5 | 82.5 | 97.4 | 87.4 | 103 | 92.4 | 109 | 97 | 114 |

| 14 | 70.1 | 67.4 | 85.4 | 89.8 | 106 | 95.6 | 113 | 101 | 120 | 107 | 127 | 112 | 133 |

| 16 | 91.6 | 88 | 111 | 117 | 139 | 125 | 148 | 132 | 156 | 140 | 165 | 147 | 173 |

| 18 | 116 | 111 | 141 | 149 | 176 | 158 | 187 | 168 | 198 | 177 | 209 | 186 | 220 |

| 20 | 143 | 138 | 174 | 184 | 217 | 195 | 231 | 207 | 224 | 219 | 258 | 230 | 271 |

| 22 | 173 | 166 | 210 | 222 | 262 | 236 | 279 | 250 | 296 | 265 | 313 | 278 | 328 |

| 24 | 206 | 198 | 251 | 264 | 312 | 281 | 332 | 298 | 352 | 315 | 372 | 330 | 390 |

| 26 | 242 | 232 | 295 | 310 | 367 | 330 | 390 | 350 | 413 | 370 | 437 | 388 | 458 |

| 28 | 280 | 270 | 342 | 360 | 425 | 384 | 453 | 406 | 480 | 429 | 507 | 450 | 531 |

| 30 | 322 | 310 | 392 | 414 | 488 | 440 | 520 | 446 | 551 | 493 | 582 | 516 | 610 |

| 32 | 366 | 352 | 446 | 471 | 556 | 501 | 591 | 531 | 627 | 561 | 662 | 588 | 694 |

| 34 | 414 | 398 | 504 | 532 | 628 | 565 | 668 | 600 | 707 | 633 | 747 | 663 | 784 |

| 36 | 464 | 446 | 565 | 596 | 704 | 634 | 748 | 672 | 793 | 710 | 838 | 744 | 878 |

| 38 | 517 | 497 | 630 | 664 | 784 | 706 | 834 | 748 | 884 | 791 | 934 | 829 | 979 |

| 40 | 572 | 550 | 698 | 736 | 869 | 782 | 924 | 830 | 979 | 876 | 1035 | 918 | 1085 |

| 42 | 631 | 607 | 769 | 811 | 958 | 863 | 1019 | 914 | 1080 | 966 | 1141 | 1013 | 1196 |

| 44 | 693 | 666 | 844 | 890 | 1051 | 947 | 1118 | 1004 | 1185 | 1060 | 1252 | 111 | 1312 |

| 46 | 757 | 730 | 922 | 973 | 1140 | 1035 | 1222 | 1090 | 1295 | 1150 | 1360 | 1215 | 1434 |

| 48 | 825 | 793 | 1004 | 1050 | 1251 | 1120 | 1331 | 1194 | 1411 | 1262 | 1490 | 1323 | 1562 |

| 50 | 895 | 860 | 1090 | 1150 | 1358 | 1223 | 1444 | 1296 | 1531 | 1369 | 1617 | 1435 | 1695 |

| 52 | 968 | 930 | 1179 | 1243 | 1468 | 1323 | 1562 | 1402 | 1655 | 1481 | 1749 | 1552 | 1833 |

| 54 | 1044 | 1003 | 1271 | 1341 | 1584 | 1426 | 1684 | 1512 | 1785 | 1597 | 1886 | 1674 | 1977 |

| 56 | 1122 | 1079 | 1367 | 1442 | 1703 | 1534 | 1812 | 1626 | 1920 | 1718 | 2029 | 1800 | 2126 |

| 58 | 1204 | 1157 | 1466 | 1547 | 1827 | 1646 | 1943 | 1744 | 2060 | 1843 | 2176 | 1931 | 2281 |

| 60 | 1288 | 1238 | 1570 | 1656 | 1955 | 1761 | 2080 | 1866 | 2204 | 1972 | 2329 | 2067 | 2441 |

8x41SW+FC Line Contacted Wire Rope

This configuration achieves a level of pliability that rivals synthetic materials, representing the absolute limit of flexibility in a steel rope. Its application is highly specific, reserved for unique, non-load-bearing roles in prototypes, research apparatus, or custom mechatronics where textile-like flexibility is required.

8x41SW+IWR Line Contacted Wire Rope

This is the essential and primary configuration for the 8x41WS class. It is the enabling component that allows its unparalleled flexibility to be utilized in real-world, load-bearing scenarios. It combines the rope’s ultimate fatigue resistance with the indispensable strength and stability of a steel core, making it the only choice for the main hoisting lines of next-generation super-compact elevators, advanced funiculars, and specialized scientific lifting systems where performance specifications are absolute.