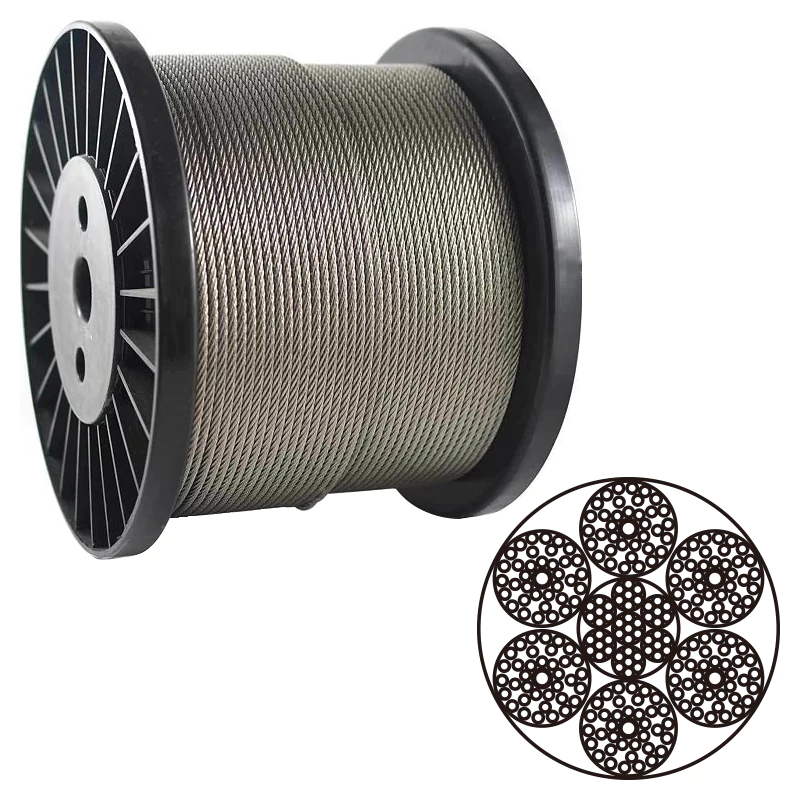

Technical Specifications for 8×49SWS Steel Wire Rope

The 8x49SWS represents the ultimate expression of what is technically possible in steel wire rope design, created for visionary projects that redefine the limits of speed, height, and mechanical complexity. This is a bespoke solution, engineered with the highest density of ultra-fine wires in a state-of-the-art, eight-strand Warrington Seale pattern.

The result is a rope with the maximum possible fatigue resistance, capable of surviving relentless, severe bending cycles that would cause any other rope to fail. It is the enabling component for the next generation of vertical transportation and advanced mechatronics.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | |||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | |||||||||

| MINIMUM BREAKING LOAD OF ROPE | |||||||||||||

| D | NF | SF | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | |||||||||||

| 8 | 22.98 | 22 | 27.9 | 29.3 | 34.7 | 31.2 | 36.9 | 33.1 | 39.1 | 35 | 41.3 | 36.7 | 43.4 |

| 9 | 29 | 27.8 | 35.3 | 37.1 | 43.9 | 39.5 | 46.7 | 41.9 | 49.5 | 44.3 | 52.3 | 46.5 | 54.9 |

| 10 | 35.9 | 34.4 | 43.6 | 45.8 | 54.2 | 48.8 | 57.6 | 51.7 | 61.1 | 54.7 | 64.6 | 57.4 | 67.8 |

| 11 | 43.3 | 42.6 | 52.7 | 55.5 | 65.5 | 59 | 69.7 | 62.6 | 73.9 | 66.2 | 78.2 | 69.5 | 82 |

| 12 | 51.5 | 49.5 | 62.8 | 66 | 78 | 70.2 | 83 | 74.5 | 88 | 78.7 | 93 | 82.7 | 97.6 |

| 13 | 60.4 | 58.1 | 73.6 | 77.5 | 91.5 | 82.5 | 97.4 | 87.4 | 103 | 92.4 | 109 | 97 | 114 |

| 14 | 70.1 | 67.4 | 85.4 | 89.8 | 106 | 95.6 | 113 | 101 | 120 | 107 | 127 | 112 | 133 |

| 16 | 91.6 | 88 | 111 | 117 | 139 | 125 | 148 | 132 | 156 | 140 | 165 | 147 | 173 |

| 18 | 116 | 111 | 141 | 149 | 176 | 158 | 187 | 168 | 198 | 177 | 209 | 186 | 220 |

| 20 | 143 | 138 | 174 | 184 | 217 | 195 | 231 | 207 | 224 | 219 | 258 | 230 | 271 |

| 22 | 173 | 166 | 210 | 222 | 262 | 236 | 279 | 250 | 296 | 265 | 313 | 278 | 328 |

| 24 | 206 | 198 | 251 | 264 | 312 | 281 | 332 | 298 | 352 | 315 | 372 | 330 | 390 |

| 26 | 242 | 232 | 295 | 310 | 367 | 330 | 390 | 350 | 413 | 370 | 437 | 388 | 458 |

| 28 | 280 | 270 | 342 | 360 | 425 | 384 | 453 | 406 | 480 | 429 | 507 | 450 | 531 |

| 30 | 322 | 310 | 392 | 414 | 488 | 440 | 520 | 446 | 551 | 493 | 582 | 516 | 610 |

| 32 | 366 | 352 | 446 | 471 | 556 | 501 | 591 | 531 | 627 | 561 | 662 | 588 | 694 |

| 34 | 414 | 398 | 504 | 532 | 628 | 565 | 668 | 600 | 707 | 633 | 747 | 663 | 784 |

| 36 | 464 | 446 | 565 | 596 | 704 | 634 | 748 | 672 | 793 | 710 | 838 | 744 | 878 |

| 38 | 517 | 497 | 630 | 664 | 784 | 706 | 834 | 748 | 884 | 791 | 934 | 829 | 979 |

| 40 | 572 | 550 | 698 | 736 | 869 | 782 | 924 | 830 | 979 | 876 | 1035 | 918 | 1085 |

| 42 | 631 | 607 | 769 | 811 | 958 | 863 | 1019 | 914 | 1080 | 966 | 1141 | 1013 | 1196 |

| 44 | 693 | 666 | 844 | 890 | 1051 | 947 | 1118 | 1004 | 1185 | 1060 | 1252 | 111 | 1312 |

| 46 | 757 | 730 | 922 | 973 | 1140 | 1035 | 1222 | 1090 | 1295 | 1150 | 1360 | 1215 | 1434 |

| 48 | 825 | 793 | 1004 | 1050 | 1251 | 1120 | 1331 | 1194 | 1411 | 1262 | 1490 | 1323 | 1562 |

| 50 | 895 | 860 | 1090 | 1150 | 1358 | 1223 | 1444 | 1296 | 1531 | 1369 | 1617 | 1435 | 1695 |

| 52 | 968 | 930 | 1179 | 1243 | 1468 | 1323 | 1562 | 1402 | 1655 | 1481 | 1749 | 1552 | 1833 |

| 54 | 1044 | 1003 | 1271 | 1341 | 1584 | 1426 | 1684 | 1512 | 1785 | 1597 | 1886 | 1674 | 1977 |

| 56 | 1122 | 1079 | 1367 | 1442 | 1703 | 1534 | 1812 | 1626 | 1920 | 1718 | 2029 | 1800 | 2126 |

| 58 | 1204 | 1157 | 1466 | 1547 | 1827 | 1646 | 1943 | 1744 | 2060 | 1843 | 2176 | 1931 | 2281 |

| 60 | 1288 | 1238 | 1570 | 1656 | 1955 | 1761 | 2080 | 1866 | 2204 | 1972 | 2329 | 2067 | 2441 |

8x49SWS+FC Line Contacted Wire Rope

This configuration achieves a fabric-like flexibility, pushing the boundaries of what a steel rope can do. Its application is exceptionally rare, reserved for unique, non-load-bearing roles in advanced scientific instruments, research prototypes, or other highly specialized mechatronic systems.

8x49SWS+IWR Line Contacted Wire Rope

This is the definitive and essential configuration for any load-bearing application of the 8x49SWS class. It synergizes the rope’s ultimate fatigue life with the indispensable strength, stability, and crush resistance of a steel core. It is the only choice for the most ambitious engineering projects, such as next-generation ultra-high-speed elevator prototypes, lifting systems for space exploration hardware, and the internal cabling for large-scale, high-precision scientific installations.