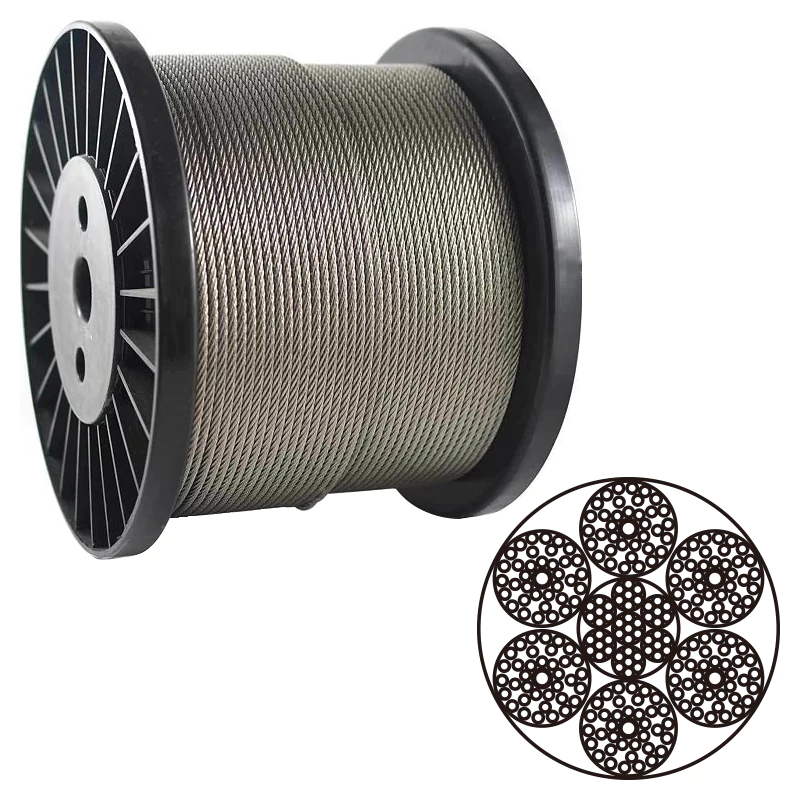

Technical Specifications for 18×7 Non-Rotating Steel Wire Rope

The 18×7 Rotation-Resistant Steel Wire Rope is a crucial safety component for a wide range of cranes and hoists. Unlike standard 6- or 8-strand ropes which tend to unwind and spin a free-hanging load, this rope is specifically engineered for stability. It features an inner layer of strands laid in one direction, covered by an outer layer of 12 strands laid in the opposite (reverse) direction.

This design generates an internal counter-torque when the rope is tensioned, effectively neutralizing the forces that cause rotation. This ensures that loads can be lifted and lowered without spinning, which is critical for operational safety, preventing damage to the load and surrounding structures, and allowing for precise placement.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | ||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | ||||||||

| MINIMUM BREAKING LOAD OF ROPE | ||||||||||||

| D | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS | FC | IWR/IWS |

| MM | KG/100M | KN | ||||||||||

| 6 | 14 | 15.5 | 17.5 | 18.5 | 18.6 | 19.7 | 19.8 | 20.9 | 20.9 | 22.1 | 21.9 | 23.1 |

| 7 | 19.1 | 21.1 | 23.8 | 25.2 | 25.4 | 26.8 | 26.9 | 28.4 | 28.4 | 30.1 | 29.8 | 31.5 |

| 8 | 25 | 27.5 | 31.1 | 33 | 33.1 | 35.1 | 35.1 | 37.2 | 37.1 | 39.3 | 38.9 | 41.1 |

| 9 | 31.6 | 34.8 | 39.4 | 41.7 | 41.9 | 44.4 | 44.4 | 47 | 47 | 49.7 | 49.2 | 52.1 |

| 10 | 39 | 43 | 48.7 | 51.5 | 51.8 | 54.8 | 54.9 | 58.1 | 58 | 61.3 | 60.8 | 64.3 |

| 11 | 47.2 | 52 | 58.9 | 62.3 | 62.6 | 66.3 | 66.4 | 70.2 | 70.1 | 74.2 | 73.5 | 77.8 |

| 12 | 56.2 | 61.9 | 70.1 | 74.2 | 74.5 | 78.9 | 79 | 83.6 | 83.5 | 88.3 | 87.5 | 92.6 |

| 13 | 65.9 | 72.7 | 82.3 | 87 | 87.5 | 92.6 | 92.7 | 98.1 | 98 | 104 | 103 | 109 |

| 14 | 76.4 | 84.3 | 95.4 | 101 | 101 | 107 | 108 | 114 | 114 | 120 | 119 | 126 |

| 16 | 99.8 | 110 | 125 | 132 | 133 | 140 | 140 | 149 | 148 | 157 | 156 | 165 |

| 18 | 126 | 139 | 158 | 167 | 168 | 177 | 178 | 188 | 188 | 199 | 197 | 208 |

| 20 | 156 | 172 | 195 | 206 | 207 | 219 | 219 | 232 | 232 | 245 | 243 | 257 |

| 22 | 189 | 208 | 236 | 249 | 251 | 265 | 266 | 281 | 281 | 297 | 294 | 311 |

| 24 | 225 | 248 | 280 | 297 | 298 | 316 | 316 | 334 | 334 | 353 | 350 | 370 |

| 26 | 264 | 291 | 329 | 348 | 350 | 370 | 371 | 392 | 392 | 415 | 411 | 435 |

| 28 | 306 | 337 | 382 | 404 | 406 | 429 | 430 | 455 | 454 | 481 | 476 | 504 |

| 30 | 351 | 387 | 438 | 463 | 466 | 493 | 494 | 523 | 522 | 552 | 547 | 579 |

| 32 | 399 | 440 | 498 | 527 | 530 | 561 | 562 | 594 | 594 | 628 | 622 | 658 |

| 34 | 451 | 497 | 563 | 595 | 598 | 633 | 634 | 671 | 670 | 709 | 702 | 743 |

| 36 | 505 | 557 | 631 | 667 | 671 | 710 | 711 | 752 | 751 | 795 | 787 | 833 |

| 38 | 563 | 621 | 703 | 744 | 748 | 791 | 792 | 838 | 837 | 886 | 877 | 928 |

| 40 | 624 | 688 | 779 | 824 | 828 | 876 | 878 | 929 | 928 | 981 | 972 | 1030 |

18×7+FC Non-Rotating Steel Wire Rope

This is a specialized, light-duty variant. Replacing the steel core with a fiber core increases the rope’s flexibility and reduces its weight. However, this comes at the cost of reduced rotation resistance and lower breaking strength. This configuration should only be considered for applications where only a moderate degree of rotation resistance is needed, and the primary requirements are flexibility and lighter weight, such as on smaller utility winches or for certain rigging applications.

18×7+IWS Non-Rotating Steel Wire Rope

This is the standard and most highly recommended configuration. The inner wire strands (the “core”) are an integral part of the rotation-resistant mechanism, providing the foundational counter-torque against the outer strands. This design offers excellent strength, crush resistance, and reliable, long-lasting stability for the vast majority of crane hoisting applications.