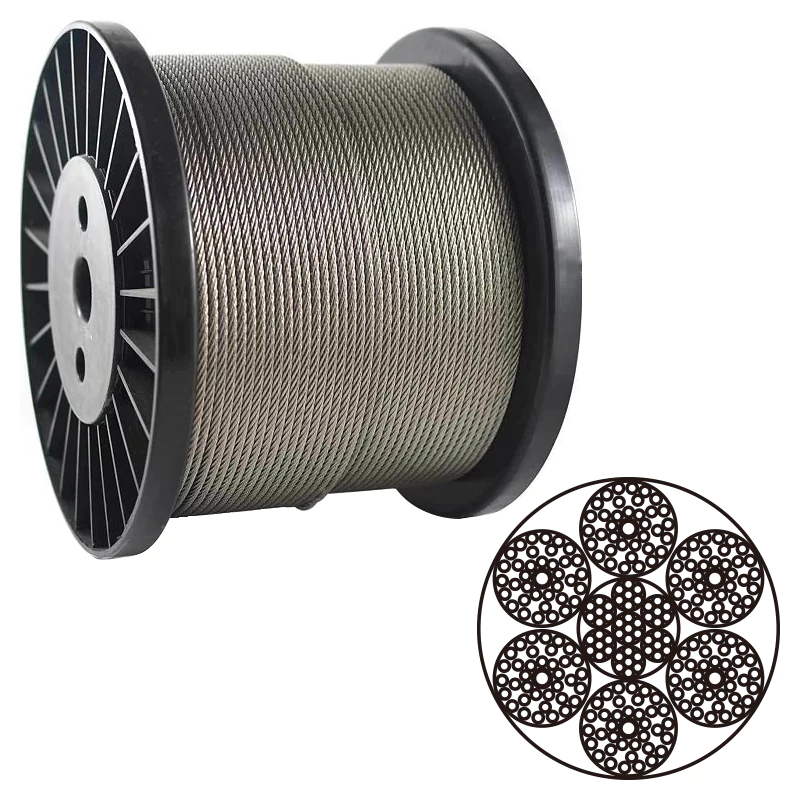

Technical Specifications for 35W×7 Multi Layers Non-Rotating Steel Wire Rope

The 35Wx7 represents the pinnacle of rotation-resistant wire rope technology, designed to provide virtually zero rotation for the most critical and challenging lifting operations. Unlike conventional 2-layer resistant ropes, the 35Wx7 features a sophisticated multi-layer, contra-helically wound design.

Multiple layers of strands are laid in opposing directions around a central core, generating a powerful and stable internal counter-torque that completely neutralizes any tendency for the rope to unwind under load. This ensures the hook block and load remain perfectly static, even when lifting from hundreds of meters, making it indispensable for applications where safety and precision are non-negotiable.

| NOMINAL DIAMETER | APPROX. WEIGHT | NOMINAL TENSILE STRENGTH OF ROPE (MPA) | ||||

| 1570 | 1670 | 1770 | 1870 | 1960 | ||

| MINIMUM BREAKING LOAD OF ROPE | ||||||

| D | ||||||

| MM | KG/100M | KN | ||||

| 8 | 29.5 | 36.1 | 38.4 | 40.7 | 43 | 45.1 |

| 10 | 46 | 56.5 | 60.1 | 63.7 | 67.3 | 70.6 |

| 12 | 66.5 | 81.4 | 86.6 | 91.8 | 96.9 | 102 |

| 14 | 90 | 111 | 118 | 125 | 132 | 138 |

| 16 | 118 | 145 | 154 | 163 | 172 | 181 |

| 18 | 149 | 183 | 195 | 206 | 218 | 229 |

| 20 | 184 | 226 | 240 | 255 | 269 | 282 |

| 22 | 223 | 274 | 291 | 308 | 326 | 342 |

| 24 | 265 | 326 | 346 | 367 | 388 | 406 |

| 26 | 311 | 382 | 406 | 431 | 455 | 477 |

| 28 | 361 | 443 | 471 | 500 | 528 | 553 |

| 30 | 414 | 509 | 541 | 573 | 606 | 635 |

| 32 | 471 | 579 | 616 | 652 | 689 | 723 |

| 34 | 532 | 653 | 695 | 737 | 778 | 816 |

| 36 | 596 | 732 | 779 | 826 | 872 | 914 |

| 38 | 664 | 816 | 868 | 920 | 972 | 1020 |

| 40 | 736 | 904 | 962 | 1020 | 1080 | 1130 |

| 42 | 811 | 997 | 1060 | 1120 | 1190 | 1240 |

| 44 | 891 | 1090 | 1160 | 1230 | 1300 | 1370 |

| 46 | 973 | 1196 | 1272 | 1348 | 1424 | 1493 |

| 48 | 1060 | 1302 | 1385 | 1468 | 1551 | 1625 |

Applications of 35W×7 Multi Layers Non-Rotating Steel Wire Rope

The high number of outer strands creates a smooth, round rope profile, which provides excellent spooling characteristics on the winch drum and minimizes wear on sheaves. Its dense, compacted construction also offers exceptional resistance to crushing and deformation. It is the mandatory specification for:

Main hoist lines on large tower cranes and mobile cranes, especially for high-rise construction.

Deep foundation drilling rigs and diaphragm wall grabs.

Shaft sinking and inspection ropes in mining and tunneling.

Critical subsea and offshore lifting operations.