Product Specifications

| G100 OMEGA LINK | ||||||||

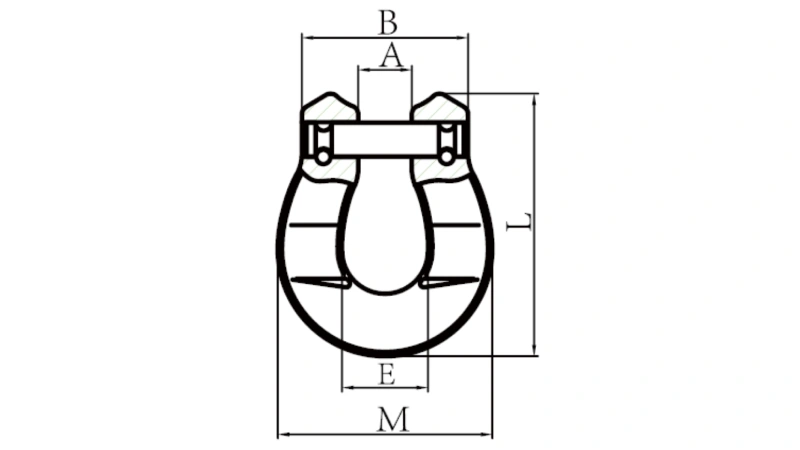

| SIZE | WEIGHT | WLL | B.L | A | B | E | M | L |

| MM | KG/PC | TON | TON | MM | MM | MM | MM | MM |

| 6 | 0.12 | 1.4 | 5.6 | 8.5 | 32.5 | 20 | 44 | 55 |

| 8 | 0.27 | 2.5 | 10 | 10.5 | 42 | 24 | 60 | 73.5 |

| 10 | 0.44 | 4 | 16 | 12.5 | 48.5 | 31 | 70 | 90 |

| 13 | 0.89 | 6.7 | 26.8 | 16 | 60 | 38.5 | 90 | 109 |

| 16 | 1.69 | 10 | 40 | 19 | 75.5 | 51 | 112 | 141.5 |

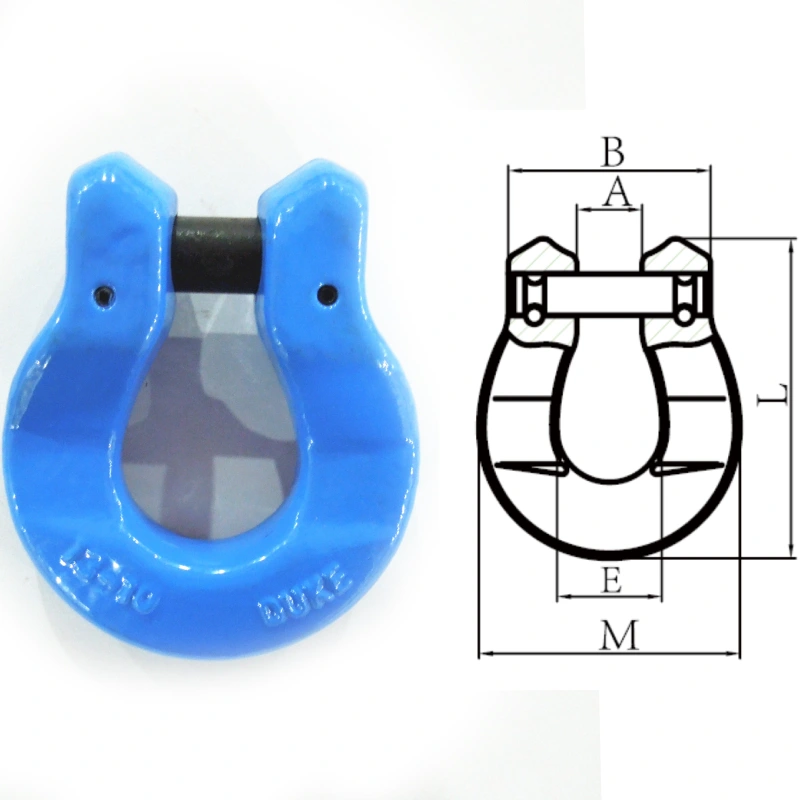

Products Diagrams

The G100 Omega Link shows its characteristic omega shape, designed to fit securely with recessed head rings and chains. This ensures a stable and reliable connection for chain slings.

The smooth, forged body highlights its thickness and strength. The seamless design reduces stress points, offering longer life and safe use under heavy-duty lifting conditions.

Material Specification

Grade: Built with Grade 100 alloy steel, providing superior strength and 25% higher load capacity than Grade 80 links.

Finish: Protected with a powder-coated or painted finish for enhanced corrosion resistance and reduced surface wear.

Attachment: Ideal for connecting recessed head rings, chains, and sling assemblies, supporting multiple rigging setups.

Hook Type: Works effectively with clevis hooks, eye hooks, and sling connectors, making it versatile in applications.

Material: High-grade forged alloy steel, ensuring durability, toughness, and compliance with global safety standards.

Application

Construction Industry

Used for lifting steel beams, prefabricated elements, and heavy equipment on construction sites with maximum reliability.

Marine & Offshore

Perfect for connecting rigging systems in shipyards, offshore oil rigs, and port operations under harsh sea conditions.

Mining Industry

Handles demanding lifting tasks for mining equipment, bulk materials, and safety-critical operations in rugged environments.

Advantages

Corrosion & Finish Protection

Rust-resistant finish ensures long-lasting protection, minimizing replacement costs for bulk buyers.

Customization & Traceability

Available in custom sizes with full batch traceability, ensuring compliance and buyer confidence.

Load Control & Durability

Forged Grade 100 design provides secure load management and reliable strength in heavy-duty lifting.

Bulk Capacity & Lead Time

Strong production capacity guarantees quick lead times and stable supply for distributors and large projects.

What Our Clients Say

FAQ

What is the primary use of a G100 Omega Link?

The G100 Omega Link is mainly used with recessed head rings and chains for chain sling assemblies. Its design ensures secure connections in lifting operations requiring multiple rigging variations.

How does Grade 100 improve performance compared to Grade 80?

Grade 100 alloy steel provides about 25% more strength, making it ideal for lifting heavier loads while using lighter components. This ensures safety, efficiency, and reduced strain on rigging.

Do you offer custom manufacturing?

Yes. Powerful Machinery provides standard and customized G100 Omega Links. We support OEM and ODM services for large distributors, enabling branded solutions and tailored specifications.

What industries use G100 Omega Links the most?

These links are popular in construction, offshore, logistics, and mining. They are chosen for their reliability, versatility, and durability under heavy-duty and safety-critical conditions.

What are your bulk order capacities and lead times?

We maintain strong production lines to support wholesale and project buyers. Standard orders usually ship in 3–4 weeks, while custom specifications take 4–6 weeks.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.