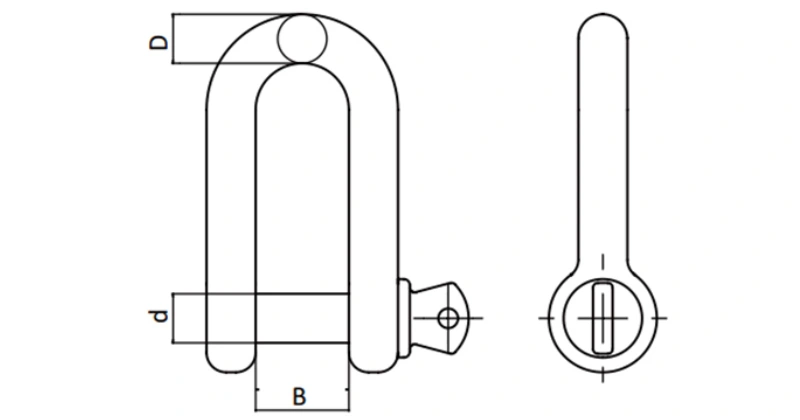

Product Specifications

| SIZE P (mm) | WLL(TON) | D(mm) | d(mm) | B(mm) |

| 6.0 | 0.5 | 6.0 | 8 | 12 |

| 8.0 | 0.75 | 8.0 | 10 | 13 |

| 10.0 | 1 | 10.0 | 11 | 17 |

| 11.0 | 1.5 | 11.0 | 13 | 18 |

| 13.0 | 2 | 13.0 | 16 | 21 |

| 16.0 | 3.2 | 16.0 | 19 | 27 |

| 19.0 | 4.7 | 19.0 | 22 | 32 |

| 22.0 | 6.5 | 22.0 | 25 | 37 |

| 25.0 | 8.5 | 25.0 | 29.0 | 43.0 |

| 29.0 | 9.5 | 29.0 | 32.0 | 46.0 |

| 32.0 | 12 | 32.0 | 35.0 | 52.0 |

| 35.0 | 13.5 | 35.0 | 38.0 | 57.0 |

| 38.0 | 17 | 38.0 | 41.0 | 60.0 |

| 44.0 | 25 | 44.0 | 51.0 | 73.0 |

| 51.0 | 35 | 51.0 | 57.0 | 83.0 |

| 63.0 | 55 | 63.0 | 70.0 | 105.0 |

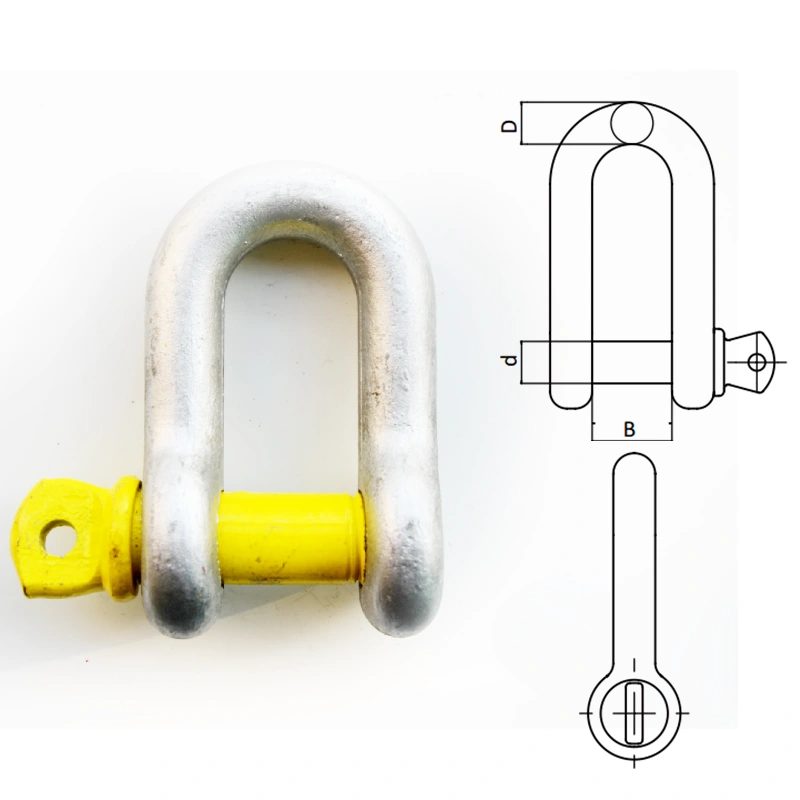

Products Diagrams

The Grade S Bow Shackle As2741 Standard features a rounded bow body with a threaded screw pin for easy assembly. Designed to distribute load evenly, it minimizes stress and prevents material fatigue.

From the side, the strong forged bow and pin connection highlight uniform thickness and accurate machining. The screw pin design allows quick attachment to chains and wire ropes during lifting operations.

Material Specification

Grade:

Manufactured to AS2741 Grade S, offering superior strength and certified load capacity for professional lifting applications.

Finish:

Hot-dip galvanized or powder-coated finish provides long-lasting corrosion resistance, ideal for harsh environments and offshore use.

Attachment:

Equipped with a secure screw pin for quick connection to chains, slings, or wire ropes, allowing fast rigging on-site.

Hook Type:

Features a Bow (Omega) Type body for multi-directional load handling and improved safety under dynamic tension.

Material:

High-tensile carbon steel or alloy steel, heat-treated and proof-tested to exceed the AS2741 standard for durability and reliability.

Application

Construction Industry

Used for connecting lifting chains and hoists in heavy construction sites, ensuring safe and efficient material movement.

Marine & Offshore

Perfect for ship mooring, cargo securing, and rigging systems exposed to saltwater environments.

Mining Industry

Handles high-load connections in hauling, rigging, and lifting operations under demanding industrial conditions.

Advantages

Corrosion & Finish Protection

Hot-dip galvanized surface protects against rust, extending service life even in marine or outdoor applications.

Customization & Traceability

Each shackle is marked with batch code and WLL; OEM logo, size, and color customization available.

Load Control & Durability

Grade S material ensures safe working load limits and outstanding fatigue resistance during repeated lifts.

Bulk Capacity & Lead Time

Large production capacity ensures stable supply and fast delivery for wholesalers and industrial buyers.

What Our Clients Say

FAQ

What is the AS2741 standard for Grade S shackles?

AS2741 defines mechanical and design requirements for forged steel shackles used in lifting applications. Our Grade S Bow Shackles meet or exceed these standards, ensuring consistent load performance and global safety compliance.

How can I confirm the load rating and certification?

Each shackle is individually proof-tested and permanently marked with WLL, size, and batch number. Certificates of conformity and mill test reports are available upon request for full traceability.

What finish options are available?

We offer hot-dip galvanization, powder coating, and electro-galvanized finishes, depending on corrosion requirements and customer preference. Custom color and branding options are available for OEM orders.

Can you produce custom sizes or private labels?

Yes. As a professional manufacturer, Powerful Machinery provides OEM and ODM services, including custom dimensions, pin types, and laser-engraved logos for brand identity.

What is your lead time and minimum order quantity?

Standard sizes are available in stock for immediate shipment. For bulk and custom orders, lead time ranges from 20–30 days, depending on quantity and specification.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.