Product Specifications

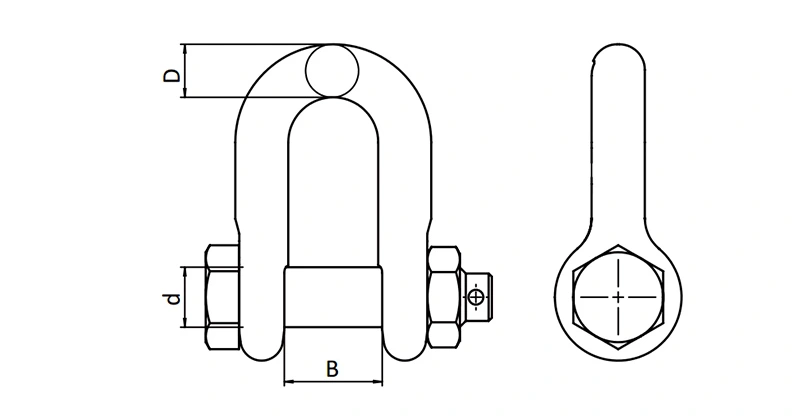

| SIZE P (mm) | WLL(TON) | D(mm) | d(mm) | B(mm) |

| 6.0 | 0.5 | 6.0 | 8 | 12 |

| 8.0 | 0.75 | 8.0 | 10 | 13 |

| 10.0 | 1 | 10.0 | 11 | 17 |

| 11.0 | 1.5 | 11.0 | 13 | 18 |

| 13.0 | 2 | 13.0 | 16 | 21 |

| 16.0 | 3.2 | 16.0 | 19 | 27 |

| 19.0 | 4.7 | 19.0 | 22 | 32 |

| 22.0 | 6.5 | 22.0 | 25 | 37 |

| 25.0 | 8.5 | 25.0 | 29.0 | 43.0 |

| 29.0 | 9.5 | 29.0 | 32.0 | 46.0 |

| 32.0 | 12 | 32.0 | 35.0 | 52.0 |

| 35.0 | 13.5 | 35.0 | 38.0 | 57.0 |

| 38.0 | 17 | 38.0 | 41.0 | 60.0 |

| 44.0 | 25 | 44.0 | 51.0 | 73.0 |

| 51.0 | 35 | 51.0 | 57.0 | 83.0 |

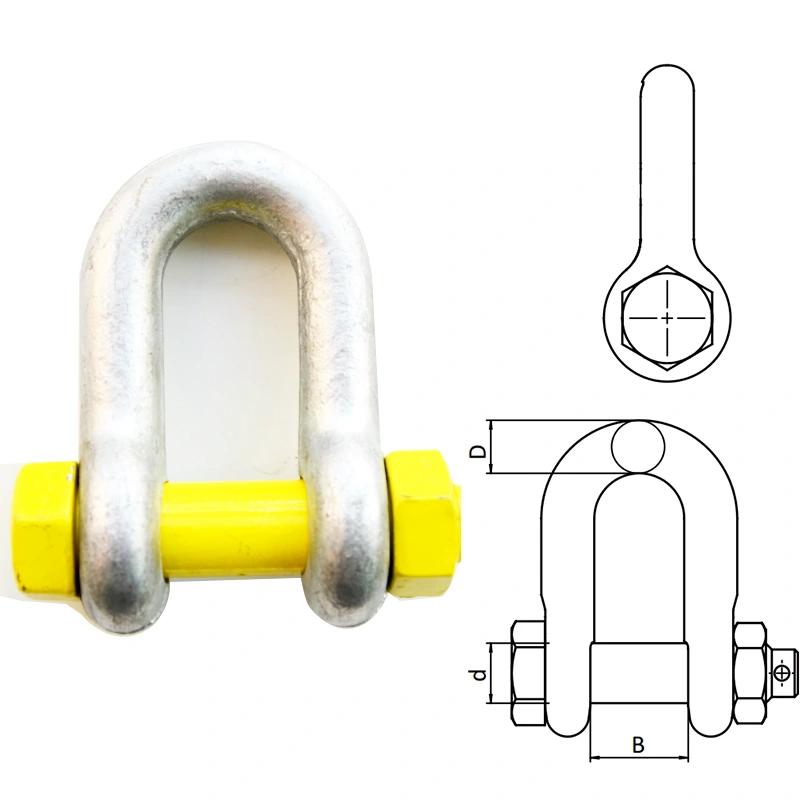

Products Diagrams

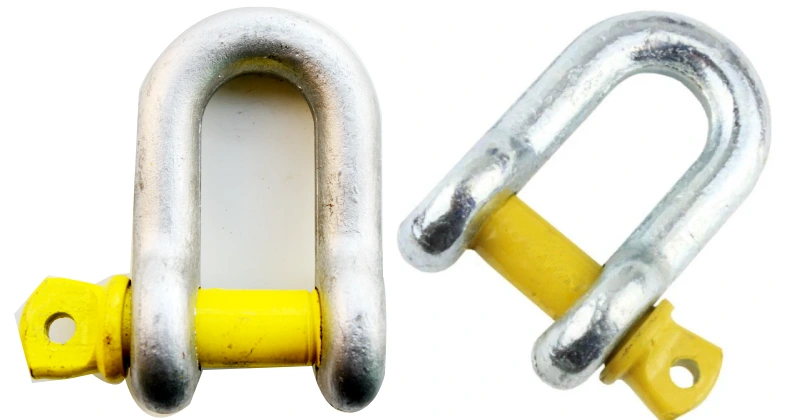

The Grade S Dee Shackle shows its strong, forged steel body and precise bolt pin design, ensuring even load distribution during lifting operations.

You can see the smooth galvanized finish and high-tensile construction. The precision threading ensures secure locking and easy maintenance.

Material Specification

Grade:

Made from Grade S high-tensile steel, ensuring superior strength and resistance to deformation under heavy load conditions.

Finish:

Hot-dip galvanized or powder-coated finish provides excellent corrosion resistance, ideal for marine and outdoor environments.

Attachment:

Compatible with chain links, wire ropes, and hooks, allowing easy integration into lifting assemblies and rigging systems.

Hook Type:

Features a secure bolt and safety nut to prevent pin rotation and ensure load stability under vibration or side movement.

Material:

High-quality carbon or alloy steel, precision-forged and heat-treated for maximum load capacity and long-term durability.

Application

Construction Industry

Used for crane lifting, scaffolding, and heavy equipment rigging where safety and load integrity are critical.

Marine & Offshore

Ideal for anchoring, mooring, and deck lifting operations under saltwater conditions due to anti-corrosion finish.

Mining Industry

Handles heavy-duty lifting, chain connection, and secure transport of mining equipment and raw materials.

Advantages

Corrosion & Finish Protection

Durable galvanized coating resists rust, ensuring long-lasting performance even in harsh weather or marine conditions.

Customization & Traceability

Each shackle can be marked with batch number, WLL, and logo for full traceability and OEM customization.

Load Control & Durability

Precision-forged steel body delivers consistent load-bearing strength and safe lifting performance in all conditions.

Bulk Capacity & Lead Time

Efficient factory production supports large orders with stable quality and fast global delivery schedules.

What Our Clients Say

FAQ

What is the load rating of your Grade S Dee Shackles As2741 Standard?

Each Grade S Dee Shackle is rigorously tested to comply with AS2741 safety standards. Working Load Limits (WLL) range from 0.5 to 25 tonnes, depending on size. The WLL and batch number are permanently stamped on every unit to ensure traceability and safe use in lifting and rigging applications.

Can I order customized shackles with my company logo?

Yes. We offer full OEM customization, including laser-engraved logos, WLL markings, and serial numbers. This helps distributors and large brands strengthen their identity and maintain quality tracking. Our engineering team can also produce shackles in non-standard dimensions or finishes based on your project needs.

Do you offer quality certifications?

Every Grade S Dee Shackle is manufactured under strict ISO9001-certified quality control. We provide Material Test Certificates (MTC), Load Test Reports, and full traceability documentation. Upon request, third-party inspection reports from agencies like SGS or BV can also be included.

What’s your delivery time for bulk orders?

We maintain large stock levels for standard sizes, allowing us to dispatch most bulk orders within 15–25 days. For OEM or custom-made shackles, production time may vary slightly depending on specifications. Our logistics team ensures safe packaging and on-time worldwide delivery.

How do I ensure the correct size for my lifting setup?

Choosing the right shackle size is crucial for safety. You can send us your chain or wire rope dimensions, and our technical engineers will recommend the best-matched shackle based on load requirements and environment. We provide free technical consultations to help you select the safest and most efficient option.

Are your Grade S Dee Shackles As2741 Standard suitable for marine or offshore environments?

Yes. Our Grade S Dee Shackles are designed with a corrosion-resistant galvanized or hot-dip finish, making them ideal for marine, offshore, and coastal applications. They maintain high load integrity even under saltwater exposure, ensuring reliable performance in shipyards, docks, and offshore platforms.

Do you perform third-party testing or provide inspection reports?

Yes, we can arrange third-party testing through accredited inspection agencies such as SGS, BV, or Lloyd’s upon customer request. Each batch is proof-tested before shipment, and we provide complete inspection documentation, including material certificates, load test data, and dimensional verification reports for full transparency.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.