Product Specifications

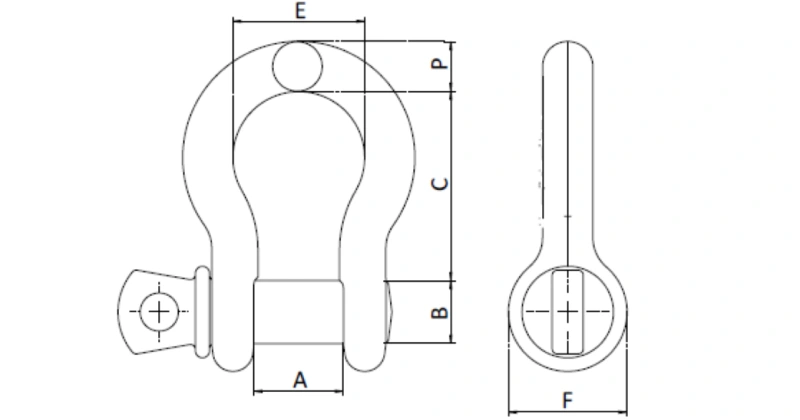

| U.S. TYPE DROP FORGED G-209 SCREW PIN ANCHOR SHACKLE | ||||||||

| NOMINAL SIZE | WLL | WEIGHT | DIMENSIONS(IN.) | |||||

| IN. | TON | KG/PC | A | B | C | P | E | F |

| 3/16″ | 1/3 | 0.02 | 3/8″ | 1/4″ | 7/8″ | 3/16″ | 11/16″ | 9/16″ |

| 1/4″ | 1/2 | 0.05 | 1/2″ | 5/16″ | 1-1/8″ | 1/4″ | 25/32″ | 11/16″ |

| 5/16″ | 3/4 | 0.09 | 17/32″ | 3/8″ | 1-7/32″ | 5/16″ | 27/32″ | 13/16″ |

| 3/8″ | 1 | 0.14 | 21/32″ | 7/16″ | 1-7/16″ | 3/8″ | 1-1/32″ | 31/32″ |

| 7/16″ | 1-1/2 | 0.17 | 23/32″ | 1/2″ | 1-11/16″ | 7/16″ | 1-5/32″ | 1-1/16″ |

| 1/2″ | 2 | 0.29 | 13/16″ | 5/8″ | 1-7/8″ | 1/2″ | 1-5/16″ | 1-3/16″ |

| 5/8″ | 3-1/4 | 0.63 | 1-1/16″ | 3/4″ | 2-3/8″ | 5/8″ | 1-11/16″ | 1-9/16″ |

| 3/4″ | 4-3/4 | 1.02 | 1-1/4″ | 7/8″ | 2-13/16″ | 3/4″ | 2″ | 1-7/8″ |

| 7/8″ | 6-1/2 | 1.53 | 1-7/16″ | 1″ | 3-5/16″ | 7/8″ | 2-9/32″ | 2-1/8″ |

| 1″ | 8-1/2 | 2.41 | 1-11/16″ | 1-1/8″ | 3-3/4″ | 1″ | 2-11/16″ | 2-3/8″ |

| 1-1/8″ | 9-1/2 | 3.09 | 1-13/16″ | 1-1/4″ | 4-1/4″ | 1-1/8″ | 2-29/32″ | 2-5/8″ |

| 1-1/4″ | 12 | 4.31 | 2-1/32″ | 1-3/8″ | 4-11/16″ | 1-1/4″ | 3-1/4″ | 3″ |

| 1-3/8″ | 13-1/2 | 6.01 | 2-1/4″ | 1-1/2″ | 5-3/16″ | 1-3/8″ | 3-1/2″ | 3-5/16″ |

| 1-1/2″ | 17 | 8.03 | 2-3/8″ | 1-5/8″ | 5-3/4″ | 1-1/2″ | 3-7/8″ | 3-5/8″ |

| 1-3/4″ | 25 | 13.78 | 2-7/8″ | 2″ | 7″ | 1-3/4″ | 5″ | 4-5/16″ |

| 2″ | 35 | 20.41 | 3-1/4″ | 2-1/4″ | 7-3/4″ | 2″ | 5-3/4″ | 5″ |

| 2-1/2″ | 55 | 38.90 | 4-1/8″ | 2-3/4″ | 10-1/2″ | 2-1/2″ | 7-1/4″ | 6″ |

| 3″ | 85 | 65 | 5″ | 3-1/4″ | 13″ | 3″ | 8″ | 7-7/8″ |

Products Diagrams

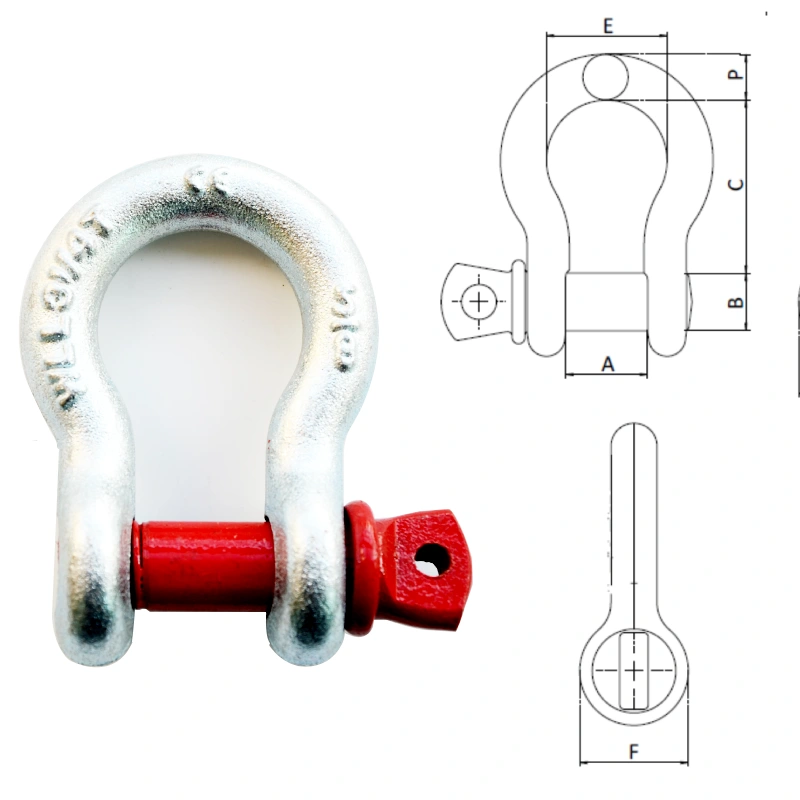

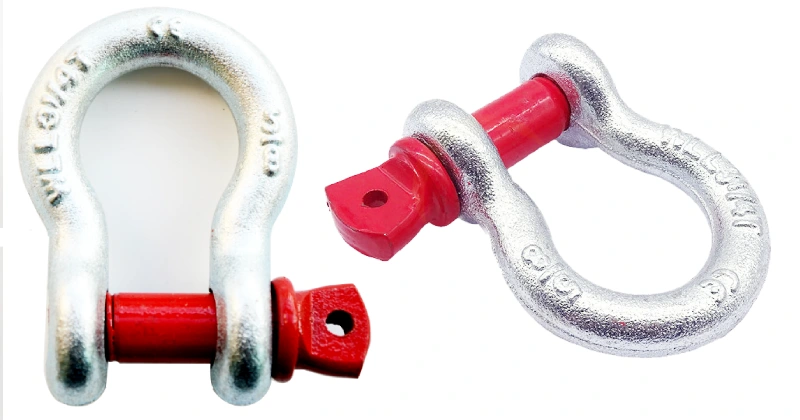

The G-209 Shackle reveals its broad bow shape, engineered for multi-directional tension. The thick forged body ensures dependable strength under dynamic load conditions.

From a close angle, the high-quality threading and screw pin design become visible, demonstrating precise forging and smooth surface treatment that prevents wear and simplifies operation.

Material Specification

Grade:

Manufactured to meet U.S. Federal Specification RR-C-271 standards, ensuring consistent load rating and safe operation under heavy lifting conditions.

Finish:

Hot-dip galvanized or electro-galvanized finish provides long-lasting corrosion resistance for indoor, outdoor, and marine environments.

Attachment:

Easily connects to wire ropes, chains, or lifting slings with quick-release screw pin for fast installation and removal.

Hook Type:

Features a rounded bow for multiple-leg sling connections, reducing side load pressure and improving lifting balance.

Material:

Drop-forged carbon steel, heat-treated for maximum strength and reliability, providing excellent durability under repeated use.

Application

Construction Industry

Used in crane lifting, rigging, and scaffold connections where quick assembly and reliable strength are essential.

Marine & Offshore

Perfect for mooring, towing, and deck rigging; resistant to corrosion and seawater exposure for long-term use.

Mining Industry

Applied in haulage, load transfer, and heavy equipment rigging; withstands abrasive, dusty, and high-load conditions.

Advantages

Corrosion & Finish Protection

Heavy-duty galvanized coating ensures long-term rust prevention and maintains a clean surface in humid or marine environments.

Customization & Traceability

Laser-marked with size, WLL, and logo for OEM branding; batch code ensures full quality traceability.

Load Control & Durability

Drop-forged body provides exceptional tensile strength and resistance to deformation under continuous lifting loads.

Bulk Capacity & Lead Time

Large-scale production supports OEM orders with fast turnaround and stable supply for global distributors.

What Our Clients Say

FAQ

What is the load capacity of your U.S. Type Drop Forged G-209 Screw Pin Anchor Shackle?

Each shackle is manufactured according to U.S. Federal Specification RR-C-271 Type IVB, with Working Load Limits (WLL) from 0.33T to 55T. Load capacity is clearly marked on each unit to ensure safe lifting operations and compliance with international standards.

Can these shackles be used for marine applications?

Yes. Our G-209 Shackles are hot-dip galvanized for corrosion resistance, making them suitable for saltwater exposure. They perform reliably in marine, offshore, and port rigging environments.

Do you offer OEM or custom branding options?

We provide OEM engraving with your company logo, load rating, and batch code. Custom color finishes and packaging are also available for distributors and large-scale projects.

What testing and certifications do your shackles have?

Each batch undergoes proof load and breaking load tests before shipment. We offer ISO9001 certification, material test reports, and third-party inspection upon request for full transparency.

What’s the lead time for bulk and customized orders?

Standard sizes are usually in stock and can ship within 15–25 days. For OEM designs or special coatings, production time depends on the order volume. Our logistics team ensures safe, timely delivery worldwide.

How should I maintain and inspect U.S. Type Drop Forged G-209 Screw Pin Anchor Shackles?

Regular inspection is essential for safety and longevity. Check the body and pin for wear, deformation, or corrosion before each use. Ensure the screw pin rotates smoothly and is fully engaged. Avoid overloading or side loading, and lubricate the threads periodically to prevent rust and improve operation during repeated use.

Are your U.S. Type Drop Forged G-209 Screw Pin Anchor Shackles compliant with international standards?

Yes. Our G-209 Shackles fully comply with U.S. Federal Specification RR-C-271 and meet or exceed ASME B30.26 requirements. Each shackle is batch-tested, proof-loaded, and stamped with identification marks for traceability. We also provide inspection certificates and mill test reports for complete compliance documentation.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.