Product Specifications

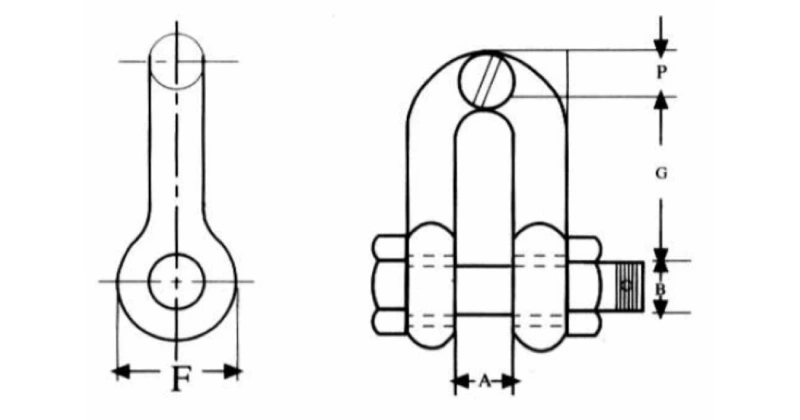

| U.S. TYPE DROP FORGED G-2150 BOLT-TYPE DEE SHACKLE | |||||||

| NOMINAL SIZE | WLL | WEIGHT | DIMENSIONS(IN.) | ||||

| IN. | TON | KG/PC | A | B | G | P | F |

| 1/2″ | 2 | 0.34 | 13/16″ | 5/8″ | 1-5/8″ | 1/2″ | 1-3/16″ |

| 5/8″ | 3-1/4 | 0.67 | 1-1/16″ | 3/4″ | 2″ | 5/8″ | 1-9/16″ |

| 3/4″ | 4-3/4 | 1.14 | 1-1/4″ | 7/8″ | 2-3/8″ | 3/4″ | 1-7/8″ |

| 7/8″ | 6-1/2 | 1.75 | 1-7/16″ | 1″ | 2-13/16″ | 7/8″ | 2-1/8″ |

| 1″ | 8-1/2 | 2.52 | 1-11/16″ | 1-1/8″ | 3-3/16″ | 1″ | 2-3/8″ |

| 1-1/8″ | 9-1/2 | 3.45 | 1-13/16″ | 1-1/4″ | 3-9/16″ | 1-1/8″ | 2-5/8″ |

| 1-1/4″ | 12 | 4.90 | 2-1/32″ | 1-3/8″ | 3-15/16″ | 1-1/4″ | 3″ |

| 1-3/8″ | 13-1/2 | 6.24 | 2-1/4″ | 1-1/2″ | 4-3/8″ | 1-3/8″ | 3-5/16″ |

| 1-1/2″ | 17 | 8.39 | 2-3/8″ | 1-5/8″ | 4-13/16″ | 1-1/2″ | 3-5/8″ |

| 1-3/4″ | 25 | 14.24 | 2-7/8″ | 2″ | 5-3/4″ | 1-3/4″ | 4-1/8″ |

| 2″ | 35 | 21.21 | 3-1/4″ | 2-1/4″ | 6-3/4″ | 2″ | 5″ |

| 2-1/2″ | 55 | 38.56 | 4-1/8″ | 2-3/4″ | 8″ | 2-1/2″ | 6″ |

| 3″ | 85 | 56.36 | 5″ | 3-1/4″ | 8-1/2″ | 3″ | 6-1/2″ |

| 3-1/2″ | 120 | — | 5-1/4″ | 3-3/4″ | — | 3-1/2″ | 8″ |

| 4″ | 150 | — | 5-1/2″ | 4-1/4″ | — | 4″ | 9″ |

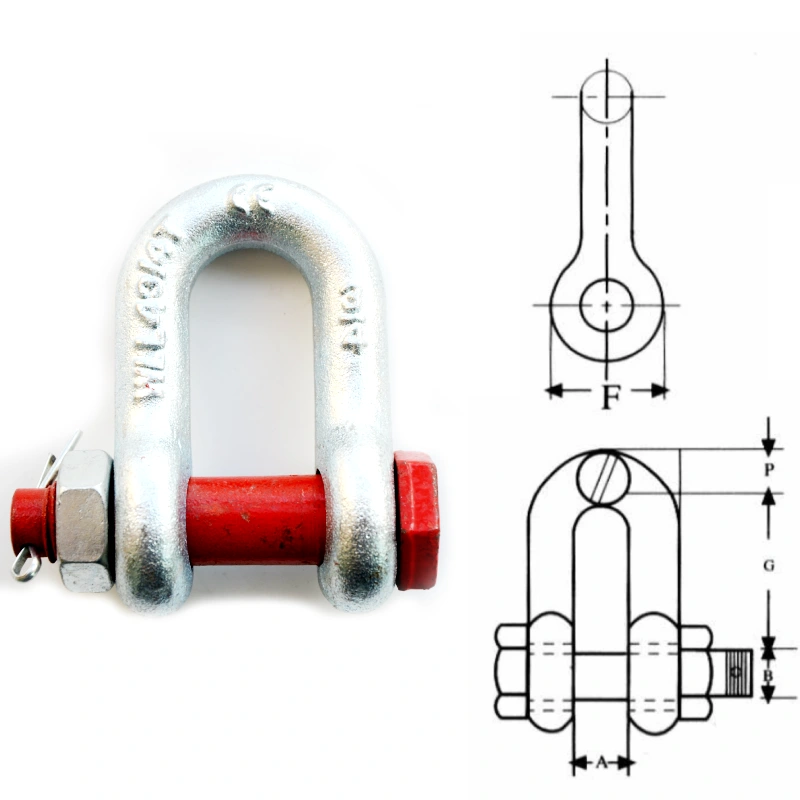

Products Diagrams

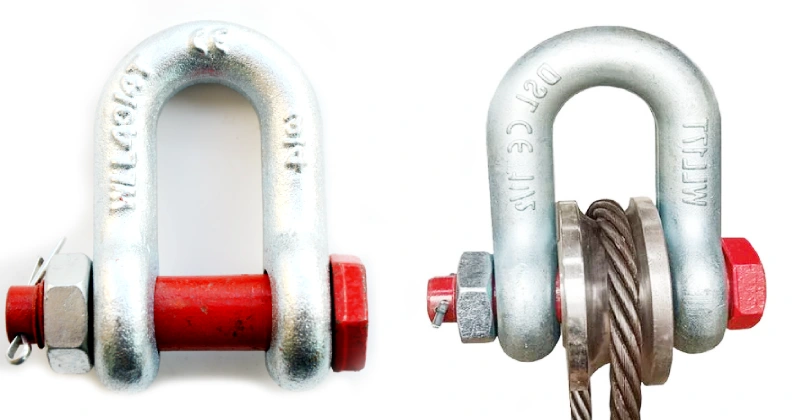

The robust “D” shape and thick drop-forged body of the G-2150 shackle. You can see the heavy-duty bolt and nut pin system that locks firmly, providing superior resistance against vibration or load shifts.

A close-up view of the precision-forged bolt mechanism highlights the safety cotter pin, ensuring secure fastening even under dynamic load conditions. The smooth galvanized surface minimizes friction and enhances longevity.

Material Specification

Manufactured to U.S. Federal Specification RR-C-271 standards, ensuring consistent strength and performance across all sizes. Ideal for demanding industrial lifting operations.

Finish:

Hot-dip galvanized finish provides long-lasting corrosion resistance, even in marine or outdoor environments. It maintains a clean, professional surface for years of heavy use.

Attachment:

Compatible with chain, wire rope, or web slings. The bolt-type pin offers a secure connection point, reducing risk of slippage during long-term or permanent installations.

Hook Type:

Bolt-type Dee shackle with nut and cotter pin for added safety. Designed to handle static and shock loads effectively without loosening under vibration.

Material:

High-tensile carbon steel, precisely drop-forged for uniform grain flow. The heat-treated structure ensures exceptional load-bearing capacity and long operational life.

Application

Construction Industry

Used for connecting lifting slings, chains, and rigging assemblies on cranes or heavy machinery for reliable and secure load handling.

Marine & Offshore

Perfect for mooring, towing, and deck lifting tasks. Its corrosion-resistant coating ensures durability in seawater conditions.

Mining Industry

Handles extreme loads in material movement, haulage, and equipment hoisting. The bolt-type lock prevents accidental release under vibration.

Advantages

Corrosion & Finish Protection

Hot-dip galvanized coating extends service life, protecting against rust and abrasion even in harsh marine or industrial environments.

Customization & Traceability

We offer size customization, logo marking, and batch traceability for industrial compliance and easy stock management.

Load Control & Durability

Precision drop-forging ensures uniform strength and safe load-bearing, preventing deformation under continuous heavy use.

Bulk Capacity & Lead Time

Large-scale production with short lead times ensures stable supply for wholesalers and distributors. OEM/ODM services available.

What Our Clients Say

FAQ

What’s the difference between a bolt-type and screw pin shackle?

A bolt-type shackle includes a bolt, nut, and cotter pin for secure fastening, preventing accidental rotation or loosening. It’s ideal for permanent or long-term connections, while screw pin shackles are better for quick, temporary setups.

Can these shackles be used in marine environments?

Yes. Our G-2150 shackles feature a hot-dip galvanized finish that provides strong resistance against seawater corrosion, making them suitable for offshore and marine applications.

What load capacities are available?

We manufacture G-2150 shackles in a full range of Working Load Limits (WLL), from 0.5 to over 55 tons. Each piece is batch-tested and certified for safety and traceability.

Can I order customized sizes or branding?

We provide custom sizes, logo stamping, and packaging solutions to support OEM/ODM orders for distributors and brands.

How fast can I get my bulk order?

Standard production lead time is 3–5 weeks, depending on order quantity. We maintain stock for popular sizes to support urgent shipments.

How do I ensure correct installation?

Always align the load in a straight line with the shackle’s body. Avoid side loading and ensure the nut and cotter pin are tightly secured before lifting operations.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.