Product Specifications

| G-402 REGULAR SWIVELS | |||||||||||

| SIZE | WLL | WEIGHT | DIMENSIONS(IN.) | ||||||||

| IN. | LBS | LBS | A | B | C | D | J | M | R | S | T |

| 1/4″ | 850 | 0.21 | 1.25 | 0.69 | 0.75 | 1.06 | 0.69 | 0.31 | 2.94 | 1.69 | 3.44 |

| 5/16″ | 1250 | 0.39 | 1.63 | 0.81 | 1 | 1.25 | 0.81 | 0.38 | 3.56 | 2.06 | 4.19 |

| 3/8″ | 2250 | 0.71 | 2 | 0.94 | 1.25 | 1.5 | 1 | 0.5 | 4.31 | 2.5 | 5.06 |

| 1/2″ | 3600 | 1.32 | 2.5 | 1.31 | 1.5 | 2 | 1.31 | 0.63 | 5.44 | 3.19 | 6.44 |

| 5/8″ | 5200 | 2.49 | 3 | 1.56 | 1.75 | 2.38 | 1.5 | 0.75 | 6.56 | 3.88 | 7.81 |

| 3/4″ | 7200 | 4.02 | 3.5 | 1.75 | 2 | 2.63 | 1.88 | 0.88 | 7.19 | 4.31 | 8.69 |

| 7/8″ | 10000 | 6.25 | 4 | 2.06 | 2.25 | 3.06 | 2.13 | 1 | 8.38 | 5 | 10.13 |

| 1″ | 12500 | 8.95 | 4.5 | 2.31 | 2.5 | 3.5 | 2.38 | 1.13 | 9.63 | 5.75 | 11.63 |

| 1-1/4″ | 18000 | 16.37 | 5.63 | 2.69 | 3.13 | 3.69 | 3 | 1.38 | 11.13 | 6.75 | 13.36 |

| 1-1/2″ | 45200 | 45.79 | 7 | 4.19 | 4 | 4.19 | 4 | 2.25 | 17.13 | 10 | 20.13 |

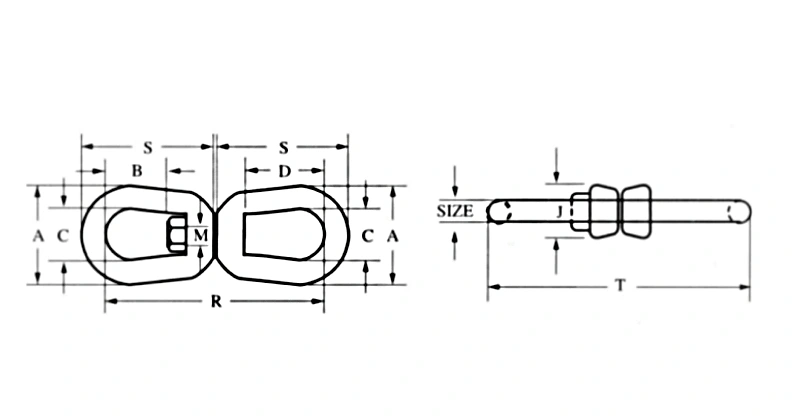

Products Diagrams

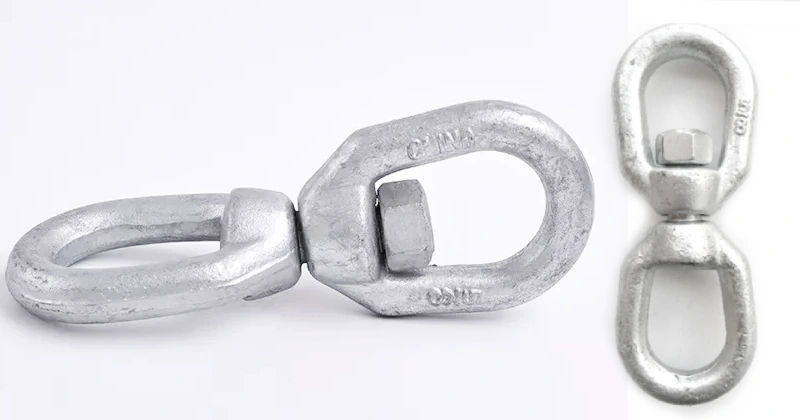

The eye-to-eye structure of the G-402 Regular Swivel emphasizes the rotational joint that minimizes rope or chain twisting and enhances load alignment in lifting or anchoring tasks.

The swivel in real-world use between mooring lines, anchor chains, or buoys highlights its ability to maintain flexibility and prevent tension buildup during operation.

Material Specification

Grade:

Manufactured from Grade 8.8 forged steel, ensuring high tensile strength, excellent load capacity, and safety under continuous heavy-duty applications.

Finish:

Hot-dip galvanized for full corrosion protection against saltwater and environmental wear, ideal for long-term outdoor and marine exposure.

Attachment:

Equipped with dual eye ends for seamless connection to chains, ropes, or hooks in lifting and mooring systems.

Regular Swivels Type:

Eye-to-eye swivel designed for easy load rotation, preventing tangling and allowing smooth movement under tension.

Material:

Made from high-quality carbon steel, precisely heat-treated and forged for durability, impact resistance, and long service life.

Application

Construction Industry

Used for load control and connection between lifting chains and slings in cranes and hoisting equipment.

Marine & Offshore

Perfect for connecting mooring buoys, anchors, and chains, providing safe rotation and corrosion resistance.

Mining Industry

Ensures stable connections for hoisting and hauling systems in harsh, abrasive working environments.

Advantages

Corrosion & Finish Protection

Hot-dip galvanization offers superior rust protection and extended lifespan, even in coastal or offshore use.

Customization & Traceability

Available with OEM engraving, batch trace codes, and size customization for brand visibility and compliance.

Load Control & Durability

Forged steel design provides smooth rotation and dependable load-bearing strength under tension.

Bulk Capacity & Lead Time

Large production capacity with strict QC ensures fast delivery and consistent quality for bulk distributors.

What Our Clients Say

FAQ

What is the main use of G-402 Regular Swivels?

G-402 Regular Swivels are used to connect two lifting or mooring components while allowing them to rotate freely. This prevents chain twisting, reduces stress, and ensures load stability in lifting or anchoring operations.

What materials are used in the G-402 Regular Swivels?

Our G-402 swivels are made from forged carbon steel, heat-treated for strength and hot-dip galvanized for corrosion resistance, ensuring safe use in marine, industrial, and construction environments.

Do you offer customization or OEM branding?

Yes. Powerful Machinery provides OEM engraving, size customization, and logo marking for distributors and large brands seeking private labeling and traceable production.

Are your swivels tested before shipment?

Each swivel is 100% proof-load tested and inspected to meet or exceed international safety standards. We provide test certificates and material mill reports upon request.

What’s your production capacity and delivery time?

We maintain large inventories for standard sizes and can deliver within 2–4 weeks. For OEM or bulk orders, production usually takes 3–5 weeks depending on specifications.

How do I choose the right swivel size for my application?

Our technical support team assists with load calculations and size matching. Provide your chain or rope dimensions, and we’ll recommend the optimal swivel type for your setup.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.