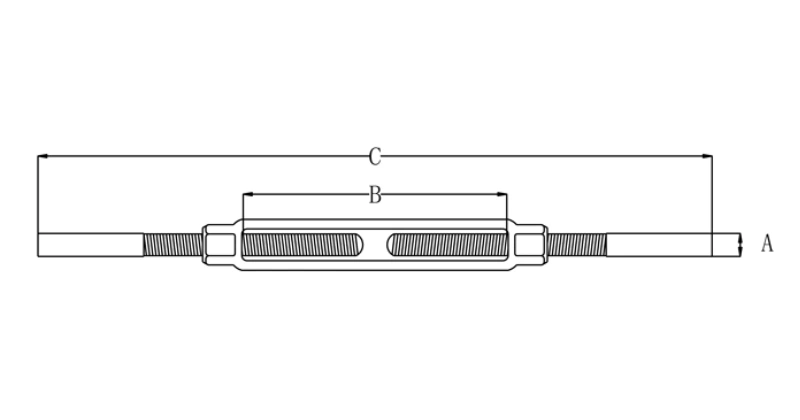

Product Specifications

| THREAD | L3 | L2 | L1 | WEIGHT(KG) |

| (MM) | (MM) | (MM) | (MM) | PER100 PCS |

| M6 | 110 | 120 | 60 | 10 |

| M8 | 110 | 120 | 65 | 16 |

| M10 | 125 | 150 | 75 | 30 |

| M12 | 125 | 150 | 75 | 40 |

| M14 | 140 | 165 | 90 | 62 |

| M16 | 170 | 200 | 100 | 96 |

| M20 | 200 | 220 | 120 | 174 |

| M22 | 220 | 220 | 120 | 213 |

| M24 | 255 | 260 | 150 | 274 |

| M27 | 255 | 265 | 160 | 388 |

| M30 | 255 | 260 | 160 | 420 |

| M36 | 295 | 300 | 180 | 720 |

| M42 | 330 | 350 | 200 | 1070 |

| M48 | 355 | 380 | 220 | 1790 |

| M56 | 355 | 380 | 230 | 2000 |

Products Diagrams

Reveals a robust, forged steel body with precisely cut threads that ensure smooth adjustment. The symmetrical stub ends allow direct connection to rods or cables, providing even load distribution and high tensile strength in industrial rigging assemblies.

The DIN1480 turnbuckle shows its elongated barrel and well-defined threading. The hot-dip galvanized coating gives a uniform metallic finish, protecting against rust and abrasion while maintaining mechanical stability during frequent tightening and loosening operations.

Material Specification

Grade:

Manufactured from Grade 40 carbon steel, ensuring consistent tensile performance and resistance to deformation under high tension loads during long-term rigging use.

Finish:

Hot-dip galvanized surface offers superior rust resistance, reducing maintenance costs and extending life even in outdoor and marine conditions.

Attachment:

Equipped with stub ends that connect directly to rods or welded eye fittings, providing fast, secure installation and adjustment flexibility.

Turnbuckle Type:

DIN1480 open-body turnbuckle allows easy visual inspection of threads and ensures precise tension control in structural or rigging applications.

Material:

High-carbon drop-forged steel, heat-treated for maximum durability and load-bearing strength in both static and dynamic environments.

Application

Construction Industry

Used for scaffolding, structural bracing, and tensioning cables, ensuring precise load adjustment and safety in buildings, bridges, and lifting structures.

Marine & Offshore

Ideal for ship rigging and mooring systems where corrosion resistance and long-term stability are critical under saltwater and vibration exposure.

Mining Industry

Provides reliable tension and alignment for conveyors and lifting frames, maintaining strength and safety under dusty and heavy-load conditions.

Advantages

Corrosion & Finish Protection

Hot-dip galvanization prevents oxidation, ensuring the product stays durable and clean even in harsh marine or outdoor conditions.

Customization & Traceability

Offered with custom sizes, markings, and full batch traceability for compliance with DIN and ISO industrial rigging standards.

Load Control & Durability

Drop-forged construction and precise threading ensure safe, stable load adjustment under heavy working stress for years of dependable use.

Bulk Capacity & Lead Time

Large-scale manufacturing enables short delivery times, stable supply, and competitive pricing for wholesalers and industrial distributors worldwide.

What Our Clients Say

FAQ

What is the function of a DIN1480 Turnbuckle Stub End?

A DIN1480 Turnbuckle Stub End is designed to adjust tension and length in cables or rods. Its threaded body allows tightening or loosening without disconnecting the assembly, ensuring fast load correction in rigging and structural applications.

What materials are used in your turnbuckles?

We use drop-forged high-carbon steel for strength and hot-dip galvanization for surface protection. This combination offers both durability and corrosion resistance, even in demanding outdoor or marine conditions.

Do you provide size customization and OEM service?

Yes, Powerful Machinery supports OEM and ODM customization. Clients can specify dimensions, thread sizes, or branding for private-label or large-scale industrial projects.

What standards do your turnbuckles meet?

All our products comply with DIN1480 standards and undergo strict mechanical testing for load capacity, thread precision, and dimensional accuracy. Each batch includes full inspection documentation.

What is your average lead time for bulk orders?

For standard sizes, delivery takes 2–3 weeks. Customized models or large quantities may require 3–5 weeks, depending on order volume and processing requirements.

Why choose Powerful Machinery as your supplier?

With over 15 years of manufacturing experience, we deliver certified, precision-engineered rigging hardware globally. Our team ensures quality consistency, competitive pricing, and reliable technical support for industrial buyers.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.