Product Specifications

| DEE-DEE TURNBUCKLES (HAMBURG) | |||||||||||

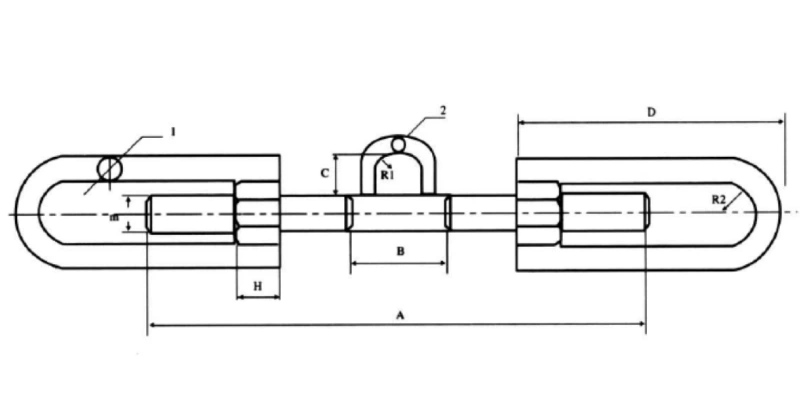

| M | A | B | C | D | H | 1 | 2 | R1 | R2 | BREAKING LOAD(T) | REMARK |

| 24 | 400 | 75 | 35 | 210 | 22 | 16 | 12 | 15 | 20 | 13 | THE FIGURES IN BRACKETS ARE ADJUSTABLE |

| 75 | 35 | 210 | 36 | 18 | 12 | 15 | 20 | (18) | |||

| 24 | 500 | 75 | 35 | 260 | 22 | 16 | 12 | 15 | 20 | 13 | |

| 75 | 35 | 260 | 36 | 18 | 12 | 15 | 20 | (18) | |||

| 27 | 400 | 75 | 35 | 210 | 33 | 20 | 12 | 17.5 | 21.5 | 20 | |

| 75 | 35 | 210 | 42 | 20 | 12 | 17.5 | 21.5 | (25) | |||

| 27 | 500 | 75 | 35 | 260 | 33 | 20 | 12 | 17.5 | 21.5 | 20 | |

| 75 | 35 | 260 | 42 | 20 | 12 | 17.5 | 21.5 | (25) | |||

| 30 | 400 | 75 | 35 | 210 | – | – | 12 | 17.5 | 22.5 | – | |

| 75 | 35 | 210 | 45 | 22 | 12 | 17.5 | 25.5 | 25 | |||

| 30 | 500 | 75 | 35 | 260 | – | – | 12 | 17.5 | 25.5 | – | |

| 75 | 35 | 260 | 45 | 22 | 12 | 17.5 | 25.5 | 25 | |||

| 30 | 480 | 80 | 35 | 255 | 40 | 25 | 12 | 20 | 28 | 30 | |

| 80 | 35 | – | – | – | – | – | – | ||||

Products Diagrams

The Dee-Dee Turnbuckle (Hamburg) displays its strong forged body with precisely threaded ends. The design ensures even load distribution and smooth adjustment, allowing accurate tension control in rigging assemblies under high load conditions.

The turnbuckle’s open-body structure and smooth galvanized finish. The compact profile ensures stability and easy handling, while the forged eye-to-eye configuration guarantees maximum alignment and strength across industrial and marine installations.

Material Specification

Grade:

Manufactured to Grade 40 carbon steel standards, providing high tensile strength and consistent load-bearing capacity across demanding industrial applications.

Finish:

Protected by hot-dip galvanization, offering superior resistance against rust, moisture, and corrosion in outdoor or marine conditions.

Attachment:

Equipped with dual eye ends that connect securely to chains, rods, or wire ropes, allowing flexible tensioning and alignment adjustments.

Dee-Dee Turnbuckles Type:

Hamburg type turnbuckle designed with open-body construction for quick visual inspection and efficient tension regulation during operations.

Material:

Made from drop-forged steel, heat-treated for increased mechanical strength, toughness, and long service life under heavy load environments.

Application

Construction Industry

Used to adjust tension in scaffolding, cable supports, and structural assemblies, ensuring stable alignment and safety during heavy construction operations.

Marine & Offshore

Perfect for mooring, ship rigging, and buoy systems where strong corrosion resistance and consistent tension control are critical.

Mining Industry

Applied in conveyor tension systems and load-bearing frameworks, maintaining performance and safety under harsh and dusty mining conditions.

Advantages

Corrosion & Finish Protection

Hot-dip galvanized surface prevents rust and damage from saltwater or weather, extending service life with minimal maintenance needs.

Customization & Traceability

Available in various sizes and markings with full batch traceability, meeting ISO and DIN industrial safety standards.

Load Control & Durability

Forged steel body and precision threads ensure strong, reliable tension control under repeated high-load cycles.

Bulk Capacity & Lead Time

Large-scale production supports bulk orders and ensures stable pricing, fast turnaround, and consistent quality for distributors and global buyers.

What Our Clients Say

FAQ

What are Dee-Dee Turnbuckles (Hamburg) used for?

These turnbuckles are used to adjust the tension between cables, rods, or chains. They’re common in construction, marine, and industrial rigging systems where load precision is critical.

What materials do you use?

We use drop-forged carbon steel with a hot-dip galvanized finish, combining high mechanical strength with excellent corrosion resistance for outdoor and marine environments.

Are your turnbuckles compliant with industry standards?

Yes. All Dee-Dee Turnbuckles (Hamburg) comply with DIN and ISO standards, with strict inspection for dimensional accuracy, thread precision, and load testing.

Can you provide OEM or custom manufacturing?

Powerful Machinery offers OEM/ODM customization, including size, thread type, marking, and packaging, tailored for distributors and large-scale industrial users.

What’s your typical lead time for orders?

Standard sizes ship within 2–3 weeks. Custom orders or large batches may require 3–5 weeks, depending on order volume and specifications.

Why choose Powerful Machinery?

We are a direct manufacturer with over 15 years of production expertise. Our factory ensures consistent quality, competitive wholesale pricing, and dependable delivery for long-term B2B clients.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.