Product Specifications

| SIZE | DIMENSIONS IN MM | WT/100PCS | ||||||

| (MM) | a | b1 | b2 | d | h1 | h2 | l | (KGS) |

| 5 | 13 | 7 | 13 | 5 | 25 | 13 | 25 | 2.08 |

| 6.5 | 17 | 8 | 16 | 6 | 32 | 14 | 30 | 4 |

| 8 | 20 | 10 | 20 | 8 | 41 | 18 | 39 | 8.2 |

| 10 | 24 | 12 | 20 | 8 | 46 | 21 | 40 | 9.2 |

| 13 | 30 | 15 | 28 | 12 | 64 | 29 | 55 | 27.5 |

| 16 | 35 | 18 | 32 | 14 | 76 | 35 | 64 | 43 |

| 19 | 36 | 22 | 32 | 14 | 83 | 40 | 68 | 49 |

| 22 | 40 | 24 | 34 | 16 | 96 | 44 | 74 | 68 |

| 26 | 50 | 26 | 38 | 20 | 111 | 51 | 84 | 117 |

| 30 | 55 | 34 | 41 | 20 | 127 | 59 | 95 | 140 |

| 34 | 60 | 38 | 45 | 22 | 141 | 67 | 105 | 213 |

| 40 | 65 | 44 | 49 | 24 | 159 | 77 | 117 | 268 |

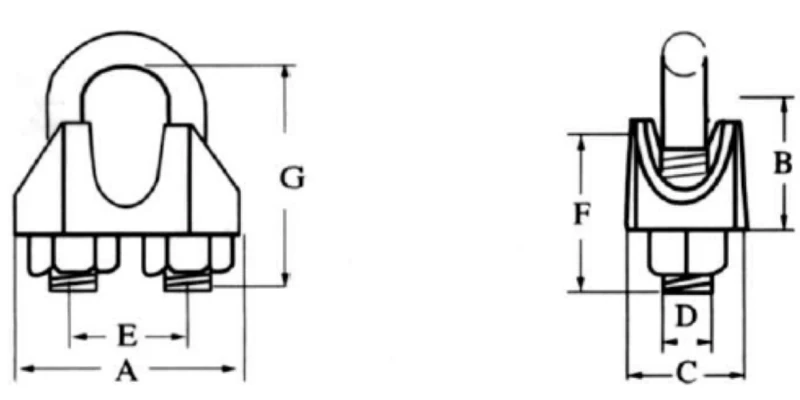

Products Diagrams

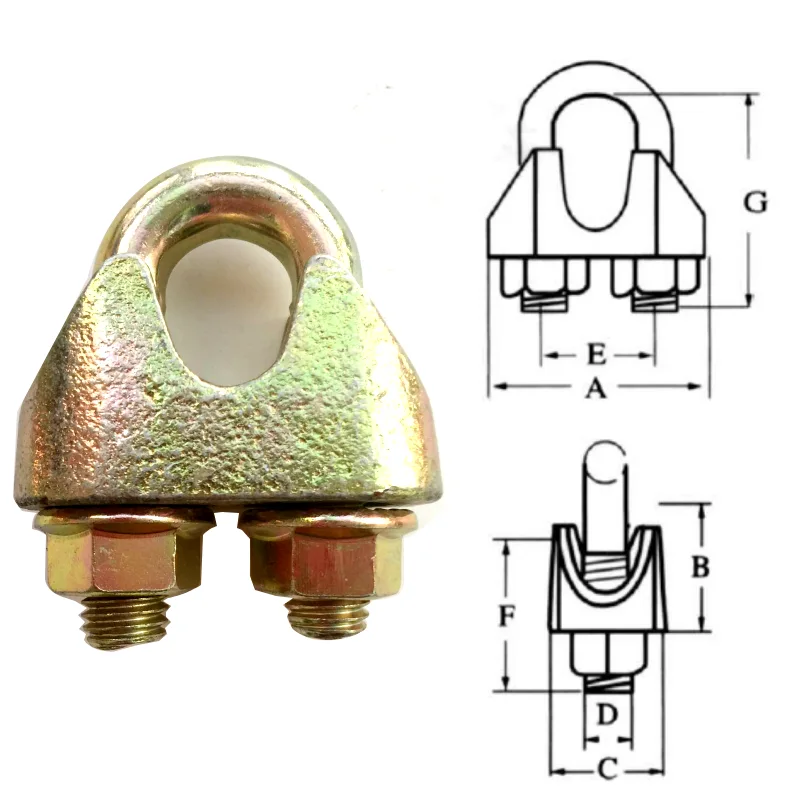

The DIN1142 Type Malleable Wire Rope Clip features a precision-engineered U-bolt and saddle for secure clamping, ensuring stable wire rope terminations under heavy load conditions.

Its dual-layer wire rope setup with strong threaded nuts provides high mechanical strength, easy installation, and reliable performance for industrial lifting, rigging, and load-securing applications.

Material Specification

Grade:

Made from high-tensile malleable iron for superior strength and shock resistance, suitable for demanding industrial applications where safety and reliability are critical.

Finish:

Zinc-plated or hot-dip galvanized surface finish offers long-lasting corrosion resistance, extending the service life even in harsh marine or outdoor environments.

Attachment:

U-bolt and saddle structure with precision-threaded nuts ensure easy tightening and secure rope connection, minimizing slippage under load.

Type:

DIN1142 standard malleable wire rope clip, designed for consistent performance and compatibility across international rigging and lifting systems.

Material:

High-quality malleable cast iron, chosen for its balance of strength, ductility, and cost-effectiveness in both construction and heavy-duty rigging use.

Application

Construction Industry

Used for securing scaffold cables, hoisting systems, and tension structures, ensuring safe load control in construction projects.

Marine & Offshore

Ideal for ship rigging, mooring lines, and cable terminations, resisting corrosion from seawater and marine conditions.

Mining Industry

Applied in lifting and haulage systems, offering high load-bearing reliability in dust-heavy and rugged mining environments.

Advantages

Corrosion & Finish Protection

Galvanized surface ensures long-term rust resistance, making it ideal for outdoor and marine use, even in humid or salty conditions.

Customization & Traceability

Offered in standard and customized sizes with full production traceability to meet your project’s safety and compliance requirements.

Load Control & Durability

Engineered for consistent clamping force and strength, it maintains load integrity under vibration or shock loads.

Bulk Capacity & Lead Time

Large-scale production capability ensures stable supply, competitive pricing, and quick lead times for global distributors.

What Our Clients Say

FAQ

What is a DIN1142 Type Malleable Wire Rope Clip used for?

The DIN1142 Type Malleable Wire Rope Clip is designed to securely fasten the loose end of a wire rope back to the main body, forming a loop or eye. It’s commonly used in rigging, hoisting, and load-bearing systems to create terminations or to join two rope sections together. These clips provide reliable grip and are ideal for general construction, marine, and industrial applications where safety and strength are essential.

How do I install a wire rope clip correctly?

To install a DIN1142 wire rope clip, first place the U-bolt over the dead end of the wire rope and position the saddle on the live end. Tighten the nuts evenly to ensure balanced pressure. Always remember the golden rule: Never saddle a dead horse!—the saddle must go on the live end for a secure hold. For safety, use the recommended number of clips and retighten after initial load testing.

Can I use malleable wire rope clips for overhead lifting?

Malleable wire rope clips are durable and versatile, but they are not recommended for overhead lifting or critical load-bearing operations where human safety is at risk. For such purposes, forged wire rope clips should be used instead, as they provide greater tensile strength and reliability under dynamic loads. Always comply with relevant safety standards before installation.

What size DIN1142 wire rope clip do I need?

The correct clip size depends on your wire rope’s diameter. As a general rule, the clip size must match the rope diameter exactly. Using an undersized or oversized clip can lead to slippage or rope damage. Our technical team provides a detailed size chart and guidance to help you select the right clip for your application.

Are custom finishes or markings available?

We supply DIN1142 Type Malleable Wire Rope Clips in multiple finishes, including zinc-plated, hot-dip galvanized, or painted coatings for extra corrosion protection. We also offer custom logo engraving or batch number markings for easy traceability and brand identity—ideal for large-scale projects and professional distributors.

What’s the typical lead time for bulk orders?

For standard sizes, our production line ensures a fast turnaround—typically 7–10 business days. Customized clips, special coatings, or private labeling may require 2–3 weeks depending on the order quantity and design complexity. As a direct manufacturer, Powerful Machinery guarantees stable supply and flexible production schedules for international buyers.

How durable are DIN1142 Type Malleable Wire Rope Clips in harsh environments?

These clips are designed for long-term performance in challenging environments. With galvanized or zinc-coated finishes, they resist rust and wear caused by humidity, saltwater, or chemical exposure. Their malleable iron construction provides excellent ductility, reducing the risk of cracking under high-stress or shock loads.

Why should I choose Powerful Machinery as my supplier?

Powerful Machinery stands out for its strict quality control, complete DIN1142 compliance, and competitive factory pricing. We serve major wholesalers, construction equipment suppliers, and marine parts distributors globally. With professional support, customizable options, and guaranteed consistency, we help your business save time, reduce cost, and gain customer trust.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.