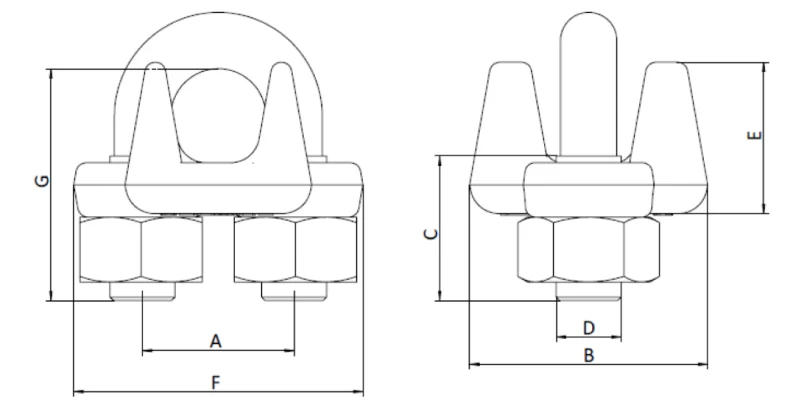

Product Specifications

| SIZE MM | A MM | B MM | C MM | D MM | E MM | F MM | G MM |

| 6 | 12 | 17 | 14 | 5 | 14 | 23 | 24.8 |

| 8 | 15 | 21 | 16 | 6 | 17 | 28 | 30.66 |

| 10 | 19 | 28 | 20 | 8 | 21 | 38 | 37.95 |

| 12 | 24 | 34 | 25 | 10 | 27 | 45 | 47.15 |

| 15 | 20 | 40 | 30 | 12 | 32 | 52 | 57.73 |

| 20 | 36 | 47 | 36 | 14 | 38 | 62 | 71.73 |

| 22 | 40 | 52 | 39 | 16 | 43 | 69 | 78.23 |

| 25 | 43 | 56 | 44 | 18 | 50 | 76 | 90.4 |

| 28 | 48 | 62 | 48 | 20 | 57 | 85 | 96.9 |

| 32 | 55 | 67 | 51 | 22 | 61 | 93 | 110.4 |

| 40 | 64 | 81 | 62 | 24 | 73 | 111 | 122.5 |

| 45 | 72 | 88 | 70 | 27 | 86 | 123 | 139.5 |

| 50 | 80 | 95 | 80 | 30 | 95 | 135 | 156 |

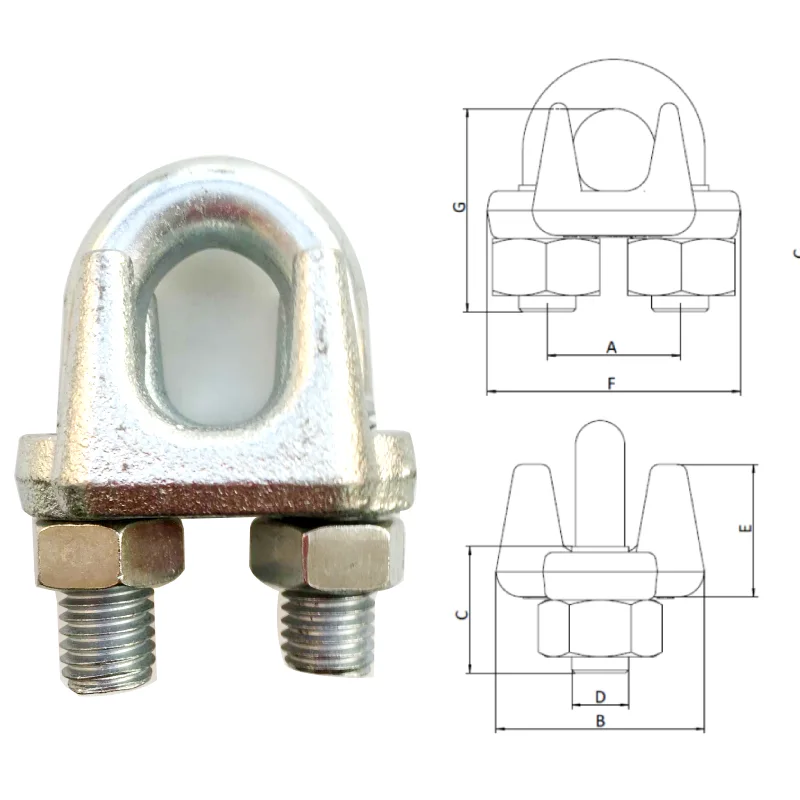

Products Diagrams

Wire Rope Clip Type A features a solid drop-forged body with precision-machined threads for reliable clamping. Its saddle and U-bolt are designed to prevent wire deformation, ensuring tight, consistent grip performance. The uniform structure enhances durability and stability under heavy load and harsh environmental conditions.

This clip’s ergonomic design allows easy, secure assembly using basic tools. The U-bolt aligns smoothly with the saddle, simplifying cable insertion and tightening. Its consistent dimensions fit various wire rope diameters, minimizing installation time and ensuring consistent strength across multiple applications in industrial lifting and rigging operations.

Material Specification

Grade:

Made from high-tensile carbon steel for superior mechanical strength, meeting or exceeding US Fed. Spec. FF-C-450 performance requirements.

Finish:

Hot-dip galvanized for long-lasting corrosion resistance, offering protection in marine, outdoor, and industrial environments.

Attachment:

Securely attaches to wire rope ends, providing a firm and safe grip that prevents slippage or deformation during heavy-duty applications.

Wire Rope Clip Type A Type:

Standard drop-forged Type A design, ensuring precise alignment, even load distribution, and consistent performance under tension.

Material:

Constructed from forged carbon steel with zinc coating, combining high durability with strong resistance to rust and environmental stress.

Application

Construction Industry

Used in scaffolding, hoisting, and cable anchoring systems, providing reliable tension and safety assurance for heavy lifting and structural connections.

Marine & Offshore

Ideal for ship rigging, mooring, and offshore cranes, offering corrosion resistance and stable cable termination in humid and saltwater environments.

Mining Industry

Applied in lifting systems, conveyors, and safety barriers, ensuring robust cable holding performance under vibration, dust, and extreme pressure.

Advantages

Corrosion & Finish Protection

The galvanized surface prevents rust and wear, ensuring long-term performance even in coastal or outdoor conditions with constant exposure to moisture and abrasion.

Customization & Traceability

Available in customized sizes with logo engraving and full batch traceability to meet OEM requirements and maintain quality control throughout the supply chain.

Load Control & Durability

Drop-forged construction maintains load integrity under stress, providing reliable tensile strength and preventing slippage during critical lifting or rigging tasks.

Bulk Capacity & Lead Time

Large-scale production capability ensures stable inventory and short delivery cycles, meeting urgent bulk demands for distributors and industrial users worldwide.

What Our Clients Say

FAQ

What is the purpose of a Wire Rope Clip Type A?

A Wire Rope Clip Type A is used to secure the loose end of a wire rope during loop or eye formation. It provides mechanical stability and prevents slippage in load-bearing applications such as hoisting, rigging, and anchoring.

What materials are used in your Wire Rope Clip Type A?

Our clips are made from high-tensile carbon steel, drop-forged for maximum strength, and hot-dip galvanized for corrosion resistance, ensuring reliability in outdoor, marine, and industrial environments.

Can you supply customized sizes or branded versions?

Yes, Powerful Machinery offers OEM and ODM customization, including branded engraving, special finishes, and packaging solutions. We tailor clip sizes and configurations to fit your specific wire rope dimensions.

Are Wire Rope Clip Type A suitable for overhead lifting?

Yes, our drop-forged Wire Rope Clip Type A meets the requirements of US Fed. Spec. FF-C-450, suitable for overhead and critical load applications when installed properly.

How many clips should I use on one wire rope connection?

The number depends on the rope diameter and safety standards. Generally, 2–3 clips are recommended for smaller diameters and up to 5 for larger, ensuring full grip and load safety.

What is your lead time for bulk Wire Rope Clip Type A orders?

Standard items are typically shipped within 7–15 days. For large OEM or custom orders, lead time depends on order quantity and production schedule. We prioritize fast delivery and quality assurance.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.