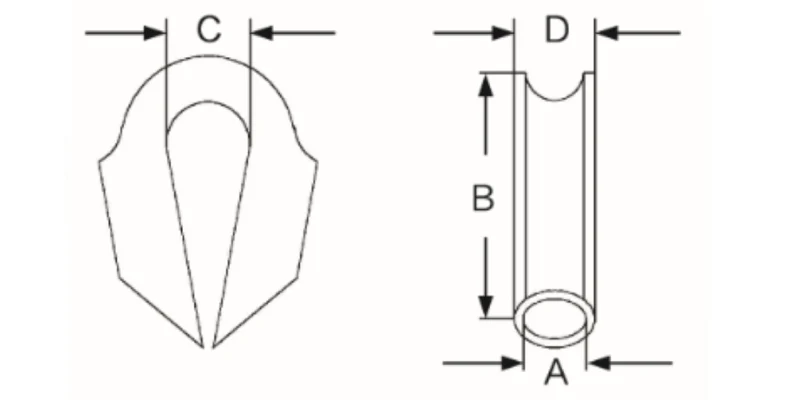

Product Specifications

| WITH OR WITHOUT GUSSET WIRE ROPE TUBULAR THIMBLE | |||||

| SIZE | DIMENSIONS(MM) | WEIGHT | |||

| IN. | A | B | C | D | KG/PC |

| 10″ | 12 | 90 | 23 | 4 | 7 |

| 12″ | 15 | 109 | 27 | 5 | 0.42 |

| 14″ | 17 | 115 | 27 | 5 | 0.5 |

| 16″ | 19 | 125 | 32 | 5 | 0.6 |

| 18″ | 22 | 140 | 35 | 5 | 0.75 |

| 22″ | 25 | 158 | 45 | 6.3 | 1.4 |

| 24″ | 28 | 180 | 45 | 7 | 1.75 |

| 26″ | 30 | 195 | 47 | 7 | 2 |

| 32″ | 35 | 215 | 60 | 7 | 2.4 |

| 38″ | 45 | 253 | 70 | 7 | 3.3 |

| 44″ | 50 | 280 | 75 | 7 | 5.5 |

Products Diagrams

The With or Without Gusset Wire Rope Tubular Thimble features a deep tube groove that firmly holds the rope line in place, preventing slippage and distortion. Its optional gusset design enhances strength for heavy loads, offering superior protection against wear, friction, and stress under continuous tension.

Engineered for easy installation, this tubular thimble ensures the wire rope stays securely aligned. The smooth tubular interior reduces abrasion, while the optional gusset provides extra reinforcement for high-load applications. It’s ideal for synthetic and steel ropes, reducing replacement costs and increasing operational safety.

Material Specification

Grade:

Manufactured from high-strength steel to ensure exceptional durability and load-bearing capacity for demanding lifting and rigging applications.

Finish:

Hot-dip galvanized or stainless steel polished finish provides superior corrosion resistance, ensuring long-lasting performance in marine and industrial settings.

Attachment:

Firmly fits at the wire rope eye termination, protecting the rope from frictional damage and keeping it properly seated during operation.

With or Without Gusset Wire Rope Tubular Thimble Type:

Available in gusseted and non-gusseted designs to suit different load and safety requirements, ensuring flexibility for various rigging systems.

Material:

Crafted from carbon steel or stainless steel, offering the perfect balance of strength, ductility, and resistance to environmental wear.

Application

Construction Industry

Used in lifting slings, hoisting systems, and structural supports to prevent wire rope deformation and ensure stable load distribution during heavy lifting.

Marine & Offshore

Ideal for mooring, towing, and marine rigging applications, offering corrosion resistance and reliability in harsh offshore environments.

Mining Industry

Used in cable terminations, conveyors, and safety harnesses, ensuring high strength, abrasion protection, and long service life in rough conditions.

Advantages

Corrosion & Finish Protection

Galvanized and stainless finishes resist corrosion, providing lasting protection against saltwater, chemicals, and outdoor elements in heavy industrial use.

Customization & Traceability

Available in custom sizes, materials, and finishes with full production traceability and laser logo marking for OEM and industrial buyers.

Load Control & Durability

The tubular body and gusset design maintain consistent tension, prevent rope deformation, and enhance durability under repetitive load cycles.

Bulk Capacity & Lead Time

Large-scale production ensures stable supply, competitive pricing, and fast global delivery to meet the needs of distributors and bulk purchasers.

What Our Clients Say

FAQ

What is a With or Without Gusset Wire Rope Tubular Thimble used for?

This thimble protects the eye of a wire rope or synthetic rope from wear, twisting, and fraying during lifting or towing. The gusseted type provides additional strength for high-load applications, while the non-gusseted type is ideal for lighter, flexible uses.

What’s the difference between gusseted and non-gusseted thimbles?

The gusseted version has a reinforced plate between the sides, increasing strength and stiffness for heavy loads. The non-gusseted version offers easier installation and flexibility for general-purpose rigging.

What materials are available for your tubular thimbles?

We manufacture them in carbon steel, stainless steel, and galvanized steel to meet various corrosion resistance and strength requirements across different industries.

Can these thimbles be used with synthetic ropes?

Yes. The tubular design keeps synthetic ropes properly aligned, reducing abrasion and extending their lifespan, making it ideal for winch and recovery lines.

Do you offer OEM or customized designs?

Yes. Powerful Machinery provides OEM services including material selection, surface treatment, custom sizes, and logo marking. We ensure consistency and quality for brand and distributor needs.

What’s your production and delivery time for bulk orders?

Standard sizes are available for quick shipment within 10–15 days. Custom orders depend on specifications but always follow strict quality control and fast lead times.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.