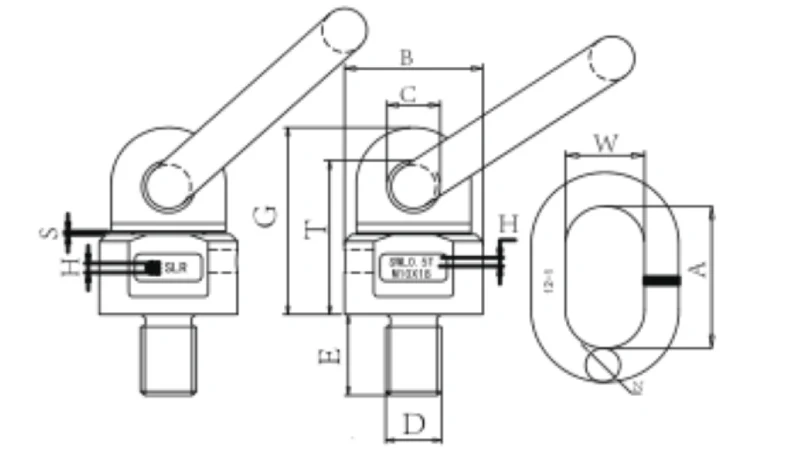

Product Specifications

| ITEM CODE | WEIGHT | WLL(T)(4:1) | D X E | B | C | G | T | A | W | N | H | S | |

| KG | WLL 90° | WLL 0° | MM | MM | MM | MM | MM | MM | MM | MM | MM | MM | |

| M8 | 0.41 | 0.3 | 0.6 | M8X13 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M10 | 0.43 | 0.5 | 0.9 | M10X18 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M10X90 | 0.38 | 0.5 | 1 | M10X90 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M12 | 0.44 | 0.5 | 1 | M12X18 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M12X40 | 0.52 | 0.5 | 1 | M12X40 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M12X45 | 0.47 | 0.5 | 1 | M12X45 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M12X110 | 0.53 | 0.5 | 1 | M12X110 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M14 | 0.45 | 1.12 | 2 | M14X20 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 |

| M16 | 0.46 | 1.12 | 2 | M16X35 | 36 | 16.5 | 52 | 42 | 55 | 30 | 14 | 3 | 1 |

| M16X40 | 0.48 | 1.12 | 2 | M16X40 | 36 | 16.5 | 52 | 42 | 55 | 30 | 14 | 3 | 1 |

| M16X100 | 0.54 | 1.12 | 2 | M16X100 | 36 | 16.5 | 52 | 42 | 55 | 30 | 14 | 3 | 1 |

| M16X120 | 0.6 | 1.12 | 2 | M16X120 | 36 | 16.5 | 52 | 42 | 55 | 30 | 14 | 3.5 | 1 |

| M20 | 0.96 | 2 | 4 | M20X30 | 49.5 | 19 | 68 | 56 | 70 | 35 | 16 | 3.5 | 1 |

| M20X120 | 1.17 | 2 | 4 | M20X120 | 49.5 | 19 | 68 | 56 | 70 | 35 | 16 | 3.5 | 1 |

| M24 | 1.45 | 3.15 | 6.3 | M24X40 | 57 | 22 | 78 | 65.5 | 85 | 40 | 18 | 3.5 | 1.5 |

| M24X40 | 1.42 | 3.15 | 6.3 | M24X90 | 57 | 22 | 78 | 65.5 | 85 | 40 | 18 | 3.5 | 1.5 |

| M24X90 | 1.66 | 3.15 | 6.3 | M24X90 | 57 | 22 | 78 | 65.5 | 85 | 40 | 18 | 3.5 | 1.5 |

| M24X120 | 1.74 | 3.15 | 6.3 | M24X120 | 57 | 22 | 78 | 65.5 | 85 | 40 | 18 | 3.5 | 1.5 |

| M27 | 1.47 | 3.15 | 6.3 | M27X35 | 57 | 22 | 78 | 65.5 | 85 | 40 | 20 | 3.5 | 1.5 |

| M30(5T) | 2.17 | 5.3 | 10.6 | M30X35 | 66 | 23.5 | 96.5 | 80.5 | 85 | 40 | 20 | 4 | 1.5 |

| M30X38 | 2.18 | 5.3 | 10.6 | M30X38 | 66 | 23.5 | 96.5 | 80.5 | 85 | 40 | 20 | 4 | 1.5 |

| M30X120 | 2.65 | 5.3 | 10.6 | M30X120 | 66 | 23.5 | 96.5 | 80.5 | 85 | 40 | 22 | 4 | 1.5 |

| M30(8T) | 3.57 | 8 | 11.8 | M30X35 | 80 | 28 | 112 | 92 | 115 | 50 | 22 | 6 | 2 |

| M30X38 | 3.58 | 8 | 11.8 | M30X38 | 80 | 28 | 112 | 92 | 115 | 50 | 22 | 6 | 2 |

| M30X120 | 4.01 | 8 | 11.8 | M30X120 | 80 | 28 | 112 | 92 | 115 | 50 | 22 | 6 | 2 |

| M36X90 | 4.17 | 8 | 11.8 | M36X90 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 |

| M36X400 | 6.41 | 8 | 11.8 | M36X400 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 |

| M39 | 3.65 | 8 | 11.8 | M39X50 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 |

| M39X90 | 3.71 | 8 | 11.8 | M39X90 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 |

| M42 | 3.62 | 10 | 15 | M42X50 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M42X60 | 6.72 | 10 | 15 | M42X60 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M42X130 | 4.46 | 10 | 15 | M42X130 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M42X180 | 5 | 10 | 15 | M42X180 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M45X60 | 4.17 | 10 | 15 | M45X60 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M48 | 4.02 | 10 | 15 | M48X50 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M48X110 | 4.8 | 10 | 15 | M48X110 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 |

| M56X84 | 11.6 | 15 | 25 | M56X84 | 117 | 42 | 310 | 280 | 152 | 70 | 32 | 7 | 2.5 |

| M64X95 | 12.4 | 15 | 25 | M64X95 | 117 | 42 | 310 | 280 | 152 | 70 | 32 | 7 | 2.5 |

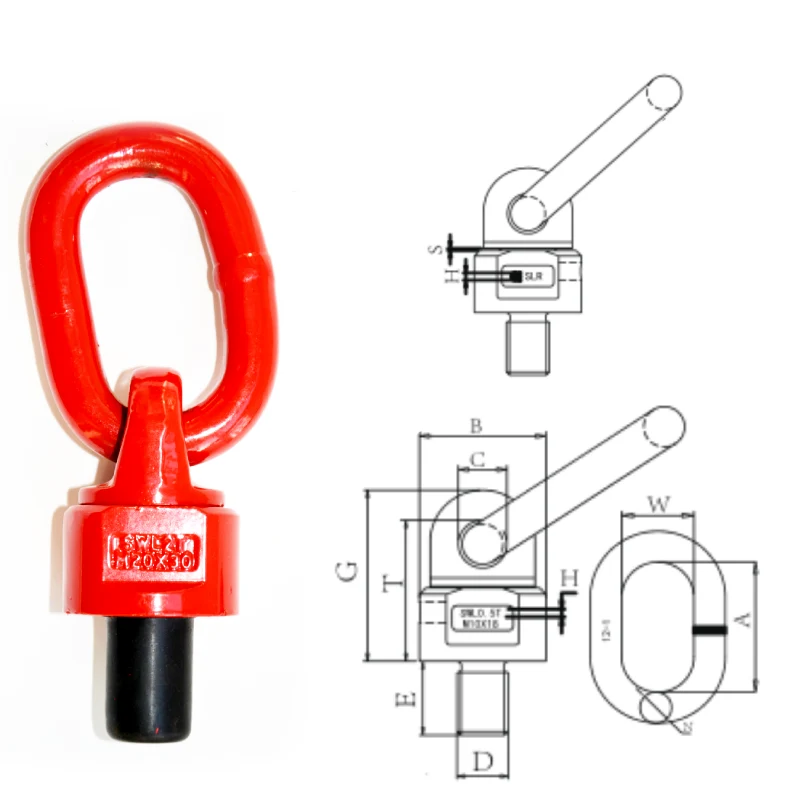

Products Diagrams

G80 Lifting Screw Points from multiple angles, detailing thread, eye, and shank dimensions. This precision ensures accurate fit, safe load distribution, and ease of integration in lifting systems.

The working load direction, attachment points, and rotational alignment. Helps engineers, purchasers, and rigging managers evaluate safe use, load control, and installation within heavy lifting equipment.

Material Specification

Grade:

Forged super alloy steel, quenched and tempered to meet G80 standard, ensuring maximum tensile strength and industrial safety compliance.

Finish:

Power-plastified surface finish provides excellent corrosion resistance, smooth handling, and reduces abrasion for long-term field use.

Attachment:

Threaded shank and lifting eye designed for secure integration with hooks, shackles, and lifting chains for safe rigging.

G80 Lifting Screw Point Type:

Available in standard or custom variants to accommodate industrial load capacities, thread sizes, and rigging requirements.

Material:

High-strength alloy steel certified for industrial lifting, fatigue resistance, and proven durability under extreme working conditions.

Application

Construction Industry

Used in cranes, scaffolding, and heavy lifting for safe, efficient handling of steel beams and structural components.

Marine & Offshore

Ideal for shipyard operations, offshore rigs, and heavy-duty marine lifting with saltwater and high-humidity resistance.

Mining Industry

Supports secure lifting of machinery, minerals, and equipment in rugged, high-stress underground and open-pit environments.

Advantages

Corrosion & Finish Protection

Power-plastified coating and alloy steel construction resist rust and abrasion, extending lifespan in harsh environmental conditions.

Customization & Traceability

OEM options, batch marking, and test reports enhance traceability and compliance with industry standards for bulk procurement.

Load Control & Durability

Individually proof-tested at 2.5× working load and fatigue-tested for 20,000 cycles, ensuring consistent industrial performance.

Bulk Capacity & Lead Time

Large-scale production ensures consistent supply with competitive lead times, ideal for distributors and industrial procurement projects.

What Our Clients Say

FAQ

What makes G80 Lifting Screw Points suitable for industrial lifting?

Forged alloy steel, quenched and tempered, tested for high fatigue, load, and breakage standards. Provides safe, reliable lifting across construction, marine, and mining applications.

What is the working load limit and testing standard?

Each point is proof-tested at 2.5× working load, fatigue-tested for 20,000 cycles, and undergoes breakage and magnaflux inspection for safety assurance.

Can these lifting points be customized?

Yes, we offer thread sizes, eye dimensions, surface finish, and OEM marking customization to meet specific rigging and industrial requirements.

How resistant are they to corrosion?

The power-plastified coating and high-grade alloy steel resist rust, abrasion, and environmental degradation, ideal for marine and outdoor use.

Are G80 Lifting Screw Points traceable?

Yes, each batch is individually tested, marked, and traceable, ensuring compliance with safety standards and facilitating inventory control for industrial buyers.

What industries commonly use these lifting points?

Construction, offshore/marine, mining, heavy machinery manufacturing, and industrial logistics—any environment requiring high-strength, reliable lifting solutions.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.