Product Specifications

| WLL(TON) | DIMENSIONS(MM) | WEIGHT | ||||||||

| CARBON | ALLOY | B | E | C | M | G | F | D | L | KG/PC |

| 3/4 | 1 | 73 | 25 | 15 | 18 | 16 | 51 | 32 | 127 | 0.23 |

| 1 | 1-1/2 | 80.3 | 25.5 | 16.7 | 20 | 18 | 58 | 35 | 147 | 0.34 |

| 1-1/2 | 2 | 92 | 30.4 | 18.4 | 23 | 22.5 | 67 | 38 | 165 | 0.45 |

| 2 | 3 | 105 | 32 | 22.4 | 26 | 24 | 69 | 41.4 | 177.5 | 0.84 |

| 3 | 5 | 126 | 38.5 | 29.5 | 32 | 29 | 82 | 51 | 216.5 | 1.75 |

| 5 | 7 | 167 | 47 | 35.8 | 40 | 36 | 95.5 | 64 | 262.5 | 3.29 |

| 7-1/2 | 11 | 192 | 61 | 46 | 51 | 47.7 | 111.2 | 76 | 323 | 6.1 |

| 10 | 15 | 214.6 | 66 | 50.8 | 55.6 | 55.5 | 114 | 82.5 | 342 | 8.2 |

| 15 | 22 | 262.5 | 89.5 | 65 | 68.8 | 68.5 | 141 | 108 | 426 | 16 |

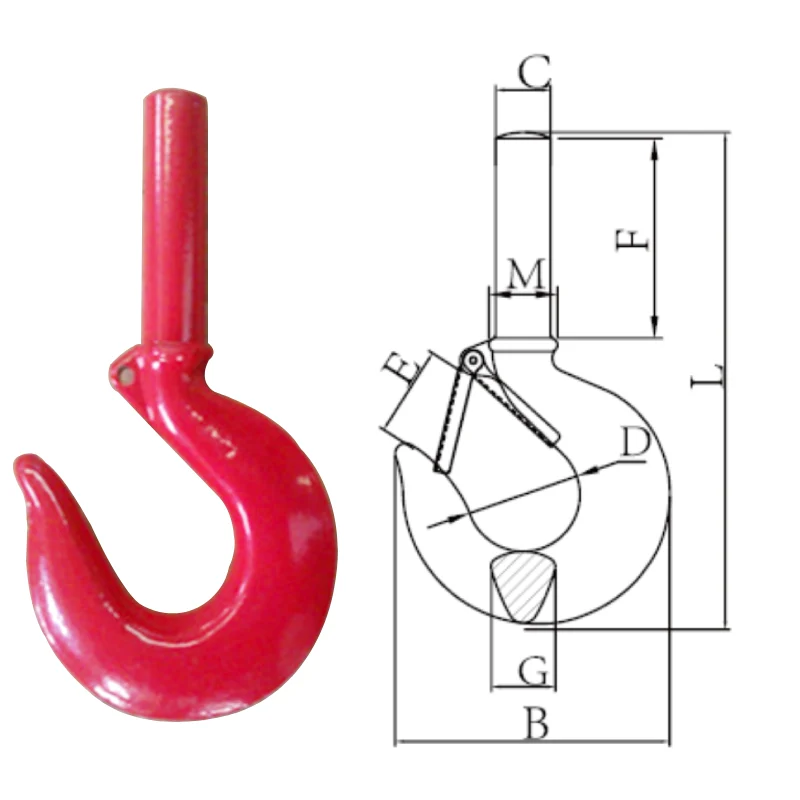

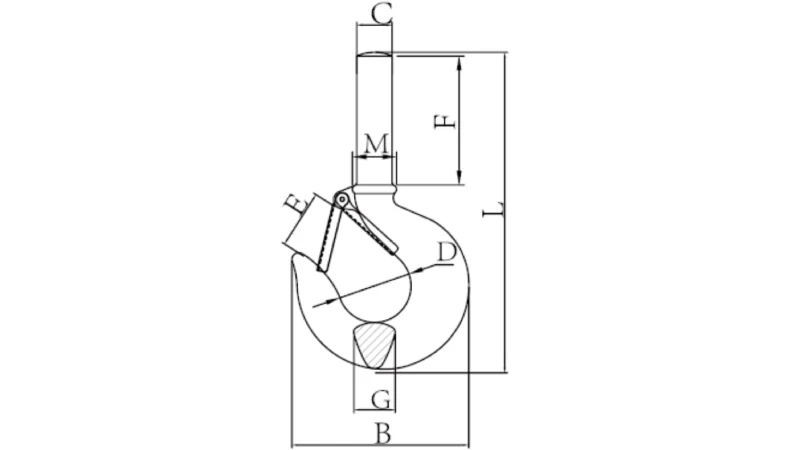

Products Diagrams

Each S-319 Forged Shank Hook is precision-forged with a reinforced shank and secure latch, ensuring maximum load integrity and operator safety during lifting and rigging tasks.

All hooks are machined with accurate dimensions and polished to a smooth finish for easy integration with chains, ropes, and lifting accessories while preventing surface abrasion.

Material Specification

Grade:

Manufactured from high-tensile Grade 80 or Grade 100 steel, ensuring exceptional load-bearing capacity and compliance with global lifting standards.

Finish:

Zinc-plated or painted surface provides enhanced corrosion protection, extending service life even in marine or outdoor environments.

Attachment:

Equipped with a threaded shank design for easy attachment to chains, slings, or mechanical assemblies in lifting systems.

S-319 Forged Shank Hooks Type:

Drop-forged shank hook with integrated spring latch for safety, ideal for chain block systems, hoists, and cranes.

Material:

Made from high-quality carbon alloy steel for superior toughness and resistance to wear under repeated loading.

Application of Shank Hooks

Construction Industry

Used for crane lifting, rigging, and securing materials, ensuring reliable load handling on construction sites and heavy projects.

Marine & Offshore

Perfect for shipbuilding, anchor handling, and offshore platforms, providing dependable performance in harsh saltwater conditions.

Mining Industry

Used in lifting machinery and material transport operations, offering strength and endurance in demanding mining environments.

Advantages

Corrosion & Finish Protection

Anti-rust coating ensures long service life, reducing maintenance costs and preventing damage in corrosive environments.

Customization & Traceability

Available in custom sizes and finishes, each unit traceable for safety compliance and quality control assurance.

Load Control & Durability

Precision-forged body provides excellent fatigue resistance and stable performance under dynamic loads.

Bulk Capacity & Lead Time

Large production capacity with efficient delivery systems guarantees consistent supply and short lead times for bulk orders.

What Our Clients Say

FAQ

What makes S-319 Forged Shank Hooks suitable for heavy-duty lifting?

Our hooks are made from forged alloy steel, providing exceptional strength and fatigue resistance. The spring latch adds an extra safety layer, preventing load slippage during use.

Can I customize the hook size and finish for specific applications?

Yes, we offer full customization, including dimensions, coating options, and threading types to fit your equipment or regional safety standards.

Are S-319 Forged Shank Hooks resistant to rust and corrosion?

Each hook is zinc-plated or powder-coated to prevent corrosion, making it ideal for marine and outdoor environments.

What certifications do your hooks comply with?

Our products meet international standards such as EN, ASME, and ISO for lifting hardware, ensuring top-tier safety and reliability.

Do you offer OEM or branding options for distributors?

Yes, we provide OEM production with custom branding, packaging, and logo printing for bulk orders, helping you expand your product range.

How can I get a quotation for bulk or customized orders?

Simply contact our sales team with your specifications. We’ll respond within 24 hours with pricing, lead time, and shipping options tailored to your needs.

What is a Shank Hook?

A shank hook is a type of lifting or rigging hook that features a long, straight, or slightly curved shank. The shank is the portion of the hook that connects to the lifting equipment or rigging system. Here’s a detailed breakdown of its features and uses:

-

Shank Design: The shank provides the structural integrity of the hook, allowing it to bear weight and handle the load. It is typically made of durable, high-strength material like steel to ensure it can withstand heavy loads without bending or breaking.

-

Variety of Applications: Shank hooks are versatile and can be used in a wide range of applications such as construction, industrial lifting, and marine operations. The length and shape of the shank can vary depending on the specific task. Longer shanks offer more clearance and flexibility, while shorter ones provide more stability and strength.

-

Improved Load Distribution: The shank is designed to evenly distribute weight along the hook, making it suitable for both vertical and angled lifting tasks. This makes it ideal for use with different types of lifting equipment, such as cranes and hoists.

-

Customizable Features: As a manufacturer, offering customizable shank hooks ensures your customers can get exactly what they need. Whether it’s a longer shank for deeper or more difficult lifts or a reinforced shank for heavy-duty applications, customization helps meet specific industry demands.

-

Durability and Safety: The shank’s design ensures the hook stays securely in place during lifting, minimizing the risk of slippage or damage to the load. Choosing a high-quality shank hook means better safety and reduced downtime, leading to a more reliable operation.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.