Product Specifications

| SIZE | b | c | e | f | g | h | SWL | WEIGHT |

| MM | MM | MM | MM | MM | MM | MM | TON | KG/PC |

| 6 | 22 | 33 | 15 | 7 | 36 | 18 | 0.1 | 0.06 |

| 8 | 22 | 33 | 15 | 7 | 36 | 18 | 0.15 | 0.06 |

| 10 | 22 | 33 | 15 | 7 | 36 | 18 | 0.25 | 0.06 |

| 12 | 22 | 33 | 15 | 7 | 36 | 18 | 0.4 | 0.06 |

| 14 | 29 | 44 | 20 | 10 | 48 | 23 | 0.5 | 0.15 |

| 16 | 29 | 44 | 20 | 10 | 48 | 23 | 0.8 | 0.15 |

| 18 | 36 | 52 | 24 | 12 | 58 | 28 | 1 | 0.27 |

| 20 | 40 | 59 | 27 | 14 | 65 | 32 | 1.6 | 0.38 |

| 22 | 45 | 64 | 30 | 14 | 73 | 35 | 1.6 | 0.54 |

| 24 | 52 | 77 | 35 | 17 | 84 | 40 | 2.5 | 0.85 |

| 27 | 58 | 85 | 39 | 20 | 94 | 46 | 2.5 | 1.13 |

| 30 | 65 | 96 | 44 | 22 | 106 | 51 | 4 | 1.62 |

| 33 | 72 | 106 | 48 | 24 | 117 | 56 | 4 | 2.37 |

| 36 | 81 | 118 | 54 | 27 | 131 | 63 | 6.3 | 3.12 |

| 39 | 86 | 123 | 57 | 29 | 137 | 67 | 6.3 | 3.81 |

| 42 | 101 | 148 | 68 | 34 | 164 | 79 | 8 | 6.27 |

| 45 | 101 | 148 | 68 | 34 | 164 | 79 | 8 | 6.45 |

| 48 | 101 | 148 | 68 | 34 | 164 | 79 | 10 | 6.51 |

| 52 | 115 | 168 | 76 | 38 | 186 | 89 | 12.5 | 9.58 |

| 56 | 128 | 188 | 86 | 43 | 208 | 100 | 16 | 12.99 |

| 64 | 144 | 212 | 96 | 48 | 234 | 112 | 20 | 18.2 |

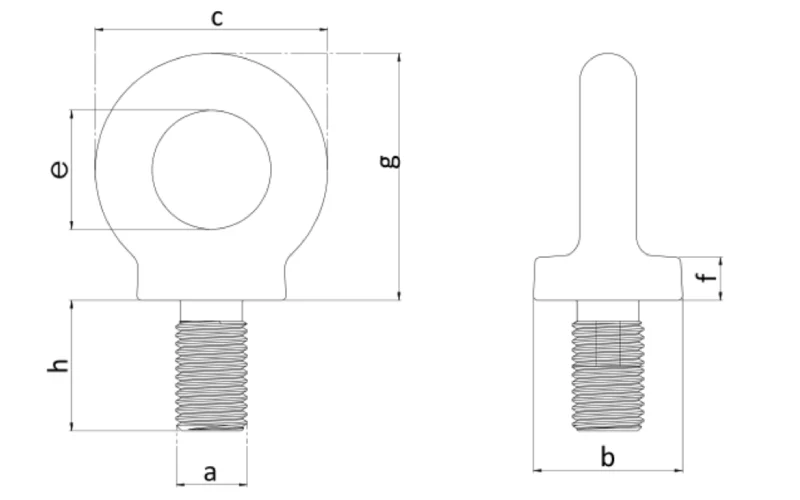

Products Diagrams

Each Bs4278 Collared Eyebolt has a reinforced shoulder design that distributes stress evenly during lifting. The precision-machined collar enhances stability and reduces deformation under high tensile loads.

The thread depth and shank alignment are engineered for perfect fitment into steel plates or machinery blocks. This ensures a secure connection and smooth torque application during installation and operation.

Material Specification

Grade:

Manufactured in Grade 8 or higher carbon/alloy steel, ensuring exceptional tensile strength and resistance to mechanical fatigue during repeated lifting operations.

Finish:

Hot-dip galvanized or zinc-plated finish provides corrosion resistance against harsh weather, moisture, and saltwater environments.

Attachment:

Designed with metric thread standards (M6–M64), allowing easy attachment to shackles, hooks, or lifting slings.

Bs4278 Collared Eyebolts Type:

According to BS4278 specification—Type A (standard) and Type B (collared)—optimized for axial or angular lifting applications.

Material:

Forged from high-grade carbon or stainless steel to ensure long-term stability, strength, and rust protection.

Application

Construction Industry

Used for hoisting machinery, pre-cast panels, and steel structures safely on construction sites.

Marine & Offshore

Ideal for mooring, rigging, and ship maintenance under high humidity and salt exposure.

Mining Industry

Applied in equipment lifting, conveyor assembly, and underground operations demanding high safety factors.

Advantages

Corrosion & Finish Protection

Zinc or galvanized coating extends product life and ensures reliable performance in corrosive marine or outdoor environments.

Customization & Traceability

Custom markings, sizes, and threading available with full batch traceability and factory test certificates for safety verification.

Load Control & Durability

Precision forging and heat-treatment processes guarantee stable load distribution and fatigue resistance under repeated lifting cycles.

Bulk Capacity & Lead Time

Large-scale production enables bulk supply with short lead times, ensuring fast delivery and cost efficiency for distributors.

What Our Clients Say

FAQ

What is a Bs4278 Collared Eyebolt used for?

It’s a lifting component designed to attach hoisting hooks or shackles securely to heavy equipment. The collared design allows safe angular loading and prevents thread damage during lifting operations.

How does it differ from a DIN580 Eyebolt?

While both serve similar purposes, the Bs4278 Collared Eyebolt has a smaller inner diameter and higher load capacity, making it better suited for industrial applications requiring stronger lifting performance.

What materials are available for Bs4278 Collared Eyebolts?

We manufacture them from carbon steel, alloy steel, or stainless steel, depending on load requirements and environmental conditions like corrosion exposure.

Can you provide test certificates or traceability documents?

Yes. Every order comes with material certificates, load-testing reports, and batch traceability to meet safety and compliance requirements for industrial and marine applications.

Do you offer custom designs or thread sizes?

As a manufacturer, we can produce non-standard dimensions, customized thread pitches, or special coatings to match your lifting and assembly needs.

What is the recommended maintenance for Collared Eyebolts?

Inspect regularly for thread wear, corrosion, or deformation. Clean after use and lubricate threads periodically to ensure smooth installation and safe load handling.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.