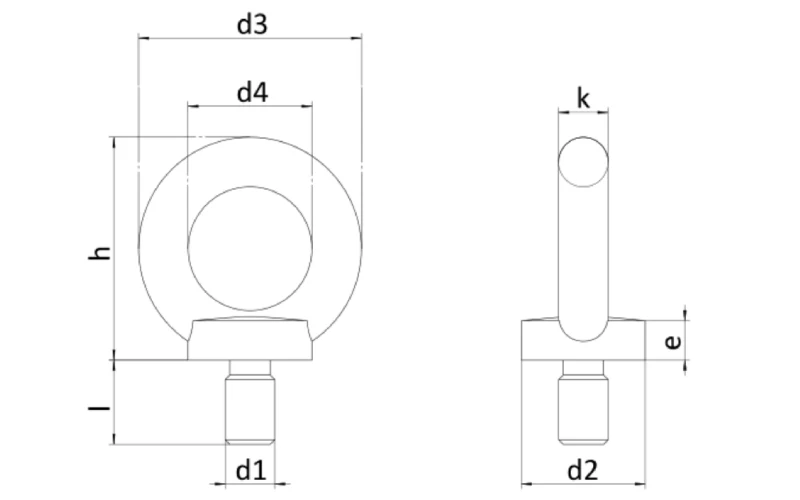

Din 580 Eye Bolt Dimensions

| SIZE(d1) | d2 | d3 | d4 | e | h | k | l | WEIGHT | WLL |

| MM | MM | MM | MM | MM | MM | MM | KG/PC | TON | |

| M6 | 20 | 36 | 20 | 6 | 36 | 8 | 13 | 0.06 | 0.08 |

| M8 | 20 | 36 | 20 | 6 | 36 | 8 | 13 | 0.06 | 0.14 |

| M10 | 25 | 45 | 25 | 8 | 45 | 10 | 17 | 0.11 | 0.23 |

| M12 | 30 | 54 | 30 | 10 | 53 | 12 | 20.5 | 0.18 | 0.34 |

| M14 | 35 | 63 | 35 | 12 | 62 | 14 | 27 | 0.28 | 0.34 |

| M16 | 35 | 63 | 35 | 12 | 62 | 14 | 27 | 0.28 | 0.7 |

| M18 | 40 | 72 | 40 | 14 | 71 | 16 | 30 | 0.45 | 0.7 |

| M20 | 40 | 72 | 40 | 14 | 71 | 16 | 30 | 0.45 | 1.2 |

| M22 | 50 | 90 | 50 | 18 | 90 | 20 | 36 | 0.87 | 1.2 |

| M24 | 50 | 90 | 50 | 18 | 90 | 20 | 36 | 0.87 | 1.8 |

| M27 | 65 | 108 | 60 | 22 | 109 | 24 | 45 | 1.66 | 1.8 |

| M30 | 65 | 108 | 60 | 22 | 109 | 24 | 45 | 1.66 | 3.2 |

| M33 | 75 | 126 | 70 | 26 | 128 | 28 | 54 | 2.65 | 3.2 |

| M36 | 75 | 126 | 70 | 26 | 128 | 28 | 54 | 2.65 | 4.6 |

| M39 | 85 | 144 | 80 | 30 | 147 | 32 | 63 | 4.03 | 4.6 |

| M42 | 85 | 144 | 80 | 30 | 147 | 32 | 63 | 4.03 | 6.3 |

| M45 | 100 | 166 | 90 | 35 | 168 | 38 | 68 | 6.38 | 6.3 |

| M48 | 100 | 166 | 90 | 35 | 168 | 38 | 68 | 6.38 | 8.6 |

| M52 | 110 | 184 | 100 | 38 | 187 | 42 | 78 | 8.8 | 8.6 |

| M56 | 110 | 184 | 100 | 38 | 187 | 42 | 78 | 8.8 | 11.5 |

| M64 | 120 | 206 | 110 | 42 | 208 | 48 | 90 | 12.4 | 16 |

| M72X6 | 150 | 260 | 140 | 50 | 260 | 60 | 100 | 23.3 | 20 |

| M80X6 | 170 | 296 | 160 | 55 | 298 | 68 | 112 | 34.2 | 28 |

| M100X6 | 190 | 330 | 180 | 60 | 330 | 75 | 130 | 49.1 | 40 |

Products Diagrams

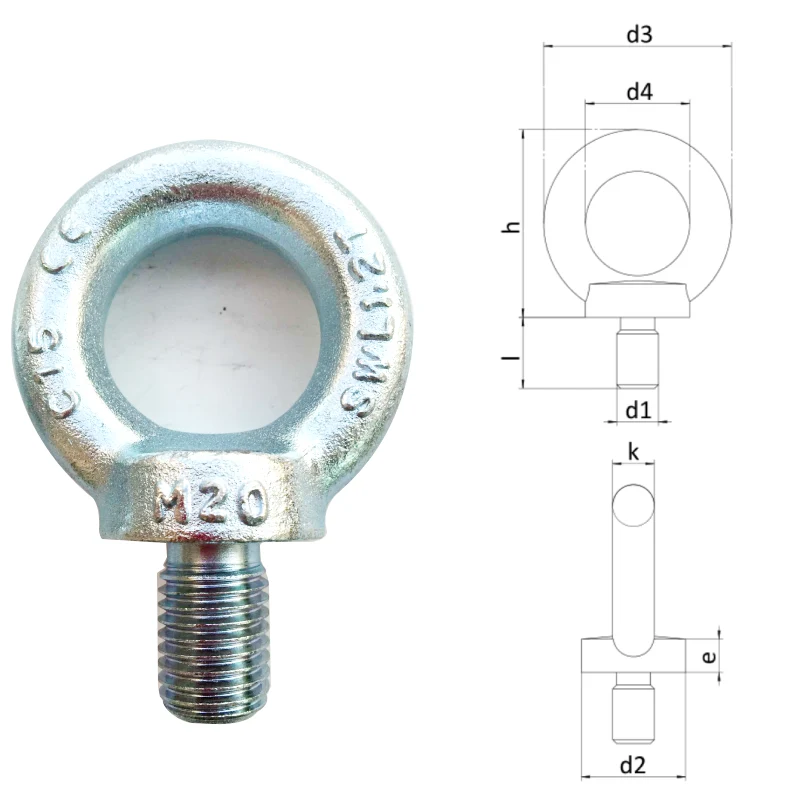

DIN580 Eye Bolts are forged to exact dimensions, ensuring consistent load alignment and secure installation. The smooth circular eye provides stable rope or hook attachment, minimizing friction during lifting operations.

Each bolt undergoes controlled heat treatment and surface finishing to resist deformation under heavy loads. The polished surface enhances corrosion resistance and extends operational lifespan in harsh environments.

Din 580 Eye Bolt Material

Grade:

Manufactured in stainless steel A2 or A4 grades for excellent mechanical strength and corrosion resistance, ideal for marine and outdoor lifting environments.

Finish:

Electropolished or zinc-plated surface ensures smooth appearance and protection from rust, oxidation, and wear caused by frequent heavy use.

Attachment:

Threaded shank provides strong, reliable connection to machinery, rigging components, or structural bases, ensuring stable load performance.

DIN580 Eye Bolts Type:

Standard forged lifting eye bolts per DIN580 specification, compatible with global lifting systems and easy to integrate with other rigging accessories.

Material:

Premium stainless steel or carbon steel options, selected based on customer load requirements and environmental exposure conditions.

Application of Din 580 Eye Bolts

Construction Industry

Used in lifting and securing heavy beams, formwork, and equipment, providing dependable anchor points for cranes and rigging operations.

Marine & Offshore

Ideal for mooring, deck lifting, and cable attachments in salty, humid conditions, ensuring safe and rust-free operation.

Mining Industry

Reliable for connecting hoisting systems and heavy machinery, ensuring strong load capacity in demanding and dusty work environments.

Advantages

Corrosion & Finish Protection

Special surface treatments prevent rust and wear, extending the lifespan of bolts in corrosive and outdoor environments.

Customization & Traceability

OEM logo marking, thread type, and material grade customization with full batch traceability for industrial buyers.

Load Control & Durability

Forged construction ensures stable performance and high load-bearing capacity under continuous stress and vibration.

Bulk Capacity & Lead Time

Large production capability guarantees fast delivery and stable quality for bulk orders, supporting project deadlines efficiently.

What Our Clients Say

FAQ of Din 580 Lifting Eye Bolt

What is the DIN580 standard for Eye Bolts?

DIN580 is a German standard defining the dimensions, load ratings, and safety factors for lifting eye bolts. It ensures compatibility and reliability across global lifting and rigging systems.

How should I choose the right size Eye Bolt?

Select the size according to load weight, installation hole size, and working angle. M6 to M36 are available, covering light-duty to heavy industrial lifting applications.

Are these Eye Bolts corrosion-resistant?

Yes. Our stainless steel A2/A4 eye bolts are resistant to corrosion, moisture, and salt, making them ideal for marine, offshore, and outdoor industrial use.

Can I order custom markings or threads?

We offer OEM customization for thread type, length, and logo marking to match your brand or project requirements.

What’s the typical load capacity of DIN580 Eye Bolts?

Load capacity varies by size—from a few hundred kilograms (M6) to several tons (M36). All eye bolts are tested and certified for rated working loads.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.