Product Specifications

| SIZE(d1) | d2 | d3 | d4 | e | h | k | r | WEIGHT | WLL |

| MM | MM | MM | MM | MM | MM | MM | KG/PC | TON | |

| M6 | 20 | 36 | 20 | 8.5 | 36 | 8 | 4 | 0.05 | 0.08 |

| M8 | 20 | 36 | 20 | 8.5 | 36 | 8 | 4 | 0.05 | 0.14 |

| M10 | 25 | 45 | 25 | 10 | 45 | 10 | 4 | 0.09 | 0.23 |

| M12 | 30 | 54 | 30 | 11 | 53 | 12 | 6 | 0.16 | 0.34 |

| M14 | 35 | 63 | 35 | 13 | 62 | 14 | 6 | 0.24 | 0.34 |

| M16 | 35 | 63 | 35 | 13 | 62 | 14 | 6 | 0.24 | 0.7 |

| M18 | 40 | 72 | 40 | 16 | 71 | 16 | 8 | 0.36 | 0.7 |

| M20 | 40 | 72 | 40 | 16 | 71 | 16 | 8 | 0.36 | 1.2 |

| M22 | 50 | 90 | 50 | 20 | 90 | 20 | 12 | 0.72 | 1.2 |

| M24 | 50 | 90 | 50 | 20 | 90 | 20 | 12 | 0.72 | 1.8 |

| M27 | 65 | 108 | 60 | 25 | 109 | 24 | 15 | 1.32 | 1.8 |

| M30 | 65 | 108 | 60 | 25 | 109 | 24 | 15 | 1.32 | 3.2 |

| M33 | 75 | 126 | 70 | 30 | 128 | 28 | 18 | 2.08 | 3.2 |

| M36 | 75 | 126 | 70 | 30 | 128 | 28 | 18 | 2.08 | 4.6 |

| M39 | 85 | 144 | 80 | 35 | 147 | 32 | 20 | 3.11 | 4.6 |

| M42 | 85 | 144 | 80 | 35 | 147 | 32 | 20 | 3.11 | 6.3 |

| M45 | 100 | 166 | 90 | 40 | 168 | 38 | 22 | 5.02 | 6.3 |

| M48 | 100 | 166 | 90 | 40 | 168 | 38 | 22 | 5.02 | 8.6 |

| M52 | 110 | 184 | 100 | 45 | 187 | 42 | 25 | 6.69 | 8.6 |

| M56 | 110 | 184 | 100 | 45 | 187 | 42 | 25 | 6.69 | 11.5 |

| M64 | 120 | 206 | 110 | 50 | 208 | 48 | 25 | 9.3 | 16 |

| M72X6 | 150 | 260 | 140 | 60 | 260 | 60 | 35 | 18.5 | 20 |

| M80X6 | 170 | 296 | 160 | 70 | 298 | 68 | 35 | 27.3 | 28 |

| M100X6 | 190 | 330 | 180 | 80 | 330 | 75 | 40 | 36.4 | 40 |

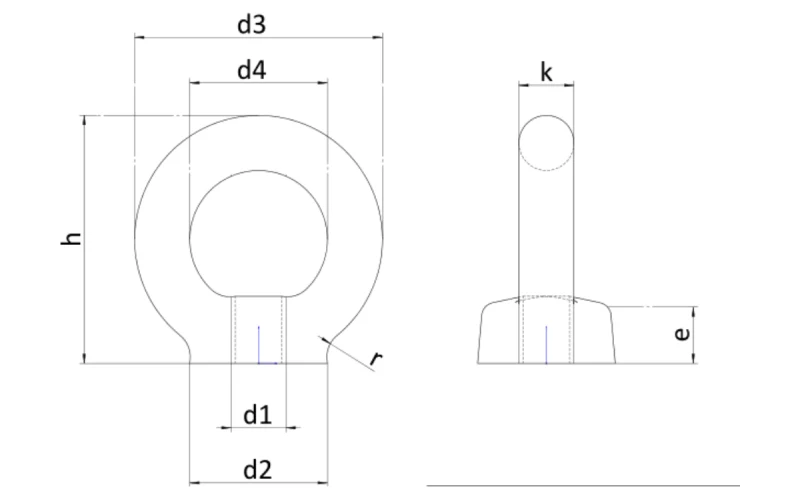

Products Diagrams

The DIN582 Eye Nut features a perfectly rounded eye with a strong threaded base, designed for precise alignment and uniform load distribution. Its compact geometry ensures safety and stability during lifting or suspension operations.

From a side and top view, the consistent wall thickness and smooth contours minimize stress points, while the polished stainless finish enhances both mechanical strength and appearance for industrial and decorative purposes.

Material Specification

Grade:

Manufactured from A2 or A4 stainless steel for exceptional strength, rust resistance, and long-term performance in demanding industrial or marine environments.

Finish:

Highly polished mirror finish offering superior corrosion resistance and a professional look suitable for visible structural or marine installations.

Attachment:

Features an internal threaded hole that connects securely to bolts, rods, or threaded bars, ensuring firm load bearing and easy installation.

DIN582 Eye Nut Type:

Standardized according to DIN582, ensuring compatibility with global lifting equipment and consistent performance across applications.

Material:

Solid stainless steel body forged under high pressure to deliver maximum mechanical strength and load capacity.

Application

Construction Industry

Used for lifting beams, securing scaffolding, and connecting load-bearing chains in construction and industrial assembly sites.

Marine & Offshore

Ideal for ship fittings, cable tension systems, and lifting components exposed to seawater or humid conditions.

Mining Industry

Applied in heavy-duty lifting operations, cable tensioning, and secure connections for underground machinery components.

Advantages

Corrosion & Finish Protection

Durable stainless steel and mirror-polished finish provide long-term protection against rust, chemicals, and harsh outdoor conditions.

Customization & Traceability

Offered with customized threading sizes, material grades, and full traceability documentation for industrial certification requirements.

Load Control & Durability

Designed with precision threading and reinforced eye structure to handle consistent heavy loads without deformation or fatigue.

Bulk Capacity & Lead Time

Large-scale production capacity and efficient supply chain ensure short lead times and competitive wholesale pricing for distributors.

What Our Clients Say

FAQ

What is a DIN582 Eye Nut used for?

A DIN582 Eye Nut is designed for lifting, securing, or suspending loads. It can be screwed onto threaded bolts or rods to create a safe lifting point for hoists, ropes, or chains.

Can DIN582 Eye Nuts be used in marine environments?

Yes, especially when made from A4 stainless steel. This material provides excellent resistance to saltwater corrosion, making it ideal for ships, docks, and offshore platforms.

What sizes are available for your DIN582 Eye Nuts?

Powerful Machinery offers standard sizes from M6 to M24, with custom dimensions available for large-scale industrial or OEM orders.

Are your Eye Nuts certified for lifting use?

Yes, all DIN582 Eye Nuts meet strict international standards and can be supplied with load capacity charts, inspection reports, and material certificates upon request.

How do I install a DIN582 Eye Nut safely?

Ensure the thread matches perfectly with the bolt or stud. Tighten securely, align the load direction, and avoid side loading to maintain safety and load efficiency.

Free Quote

Contact us for product details, pricing or technical support. Just send an email and we’ll respond immediately with an accurate and complete solution.